Method for preparing multi-scale nano-composite structure through laser cleaning assisted laser ablation

A technology of laser cleaning and composite structure, which is applied in laser welding equipment, cleaning methods and appliances, cleaning methods using liquids, etc., can solve problems such as complex equipment, increased processing costs, and reduced wave-absorbing characteristics, so as to improve wave-absorbing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] A method for preparing a multi-scale micro-nano composite structure by laser cleaning assisted by laser ablation, comprising the following steps:

[0022] 1) Ultrasonic cleaning is performed on the surface of the single crystal silicon wafer sample 7 with acetone and absolute alcohol respectively, and the surface of the single crystal silicon wafer sample is cleaned by drying with cold wind;

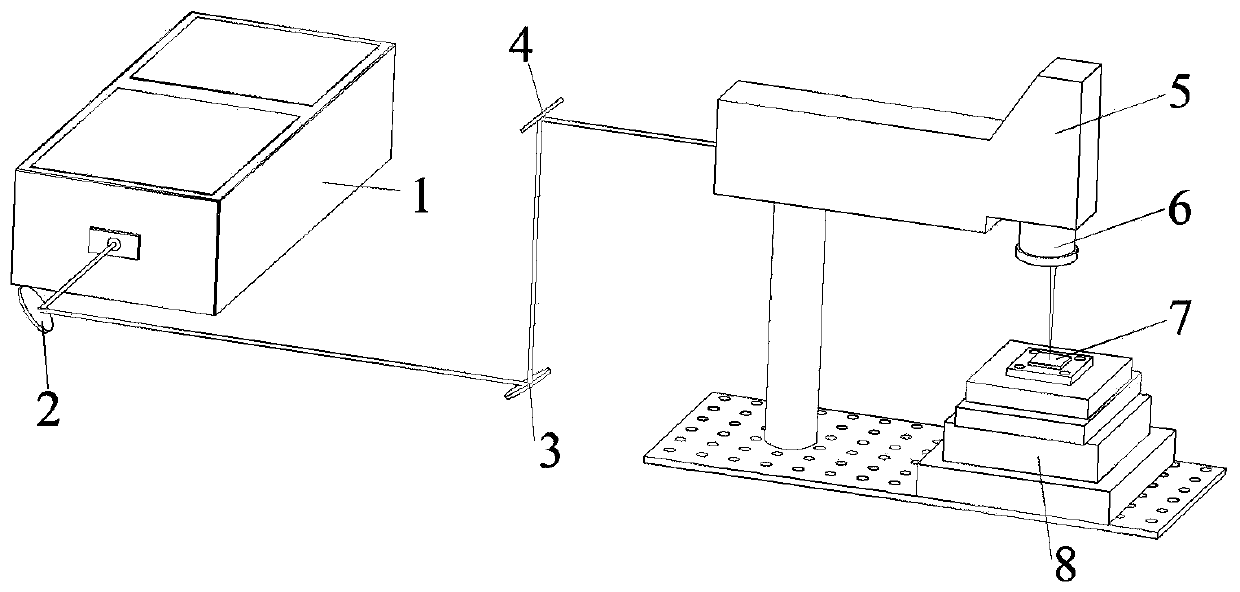

[0023] 2) Build the optical path, refer to figure 1 , the optical path includes a femtosecond laser 1, the output light of the femtosecond laser 1 passes through the first reflector 2, the second reflector 3, and the third reflector 4 and then enters the scanning vibrating mirror 5, and the light passes through the circular lens lens 6 of the scanning vibrating mirror 5 After focusing, it is irradiated on the stage 8, the femtosecond laser 1, the scanning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com