Preparation method of six-membered spinel type iron-cobalt-chromium-manganese-magnesium-copper high-entropy oxide and powder thereof

An iron-cobalt-chromium-manganese-magnesium-copper-based, spinel-type technology is applied in the field of high-entropy oxide powder materials, which can solve the problems of high raw material cost, complex process, long holding time, etc., and achieves uniform distribution, simple operation, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a six-element spinel-type iron-cobalt-chromium-manganese-magnesium-copper-based high-entropy oxide and its powder, comprising the following steps:

[0028] Step 1, mix:

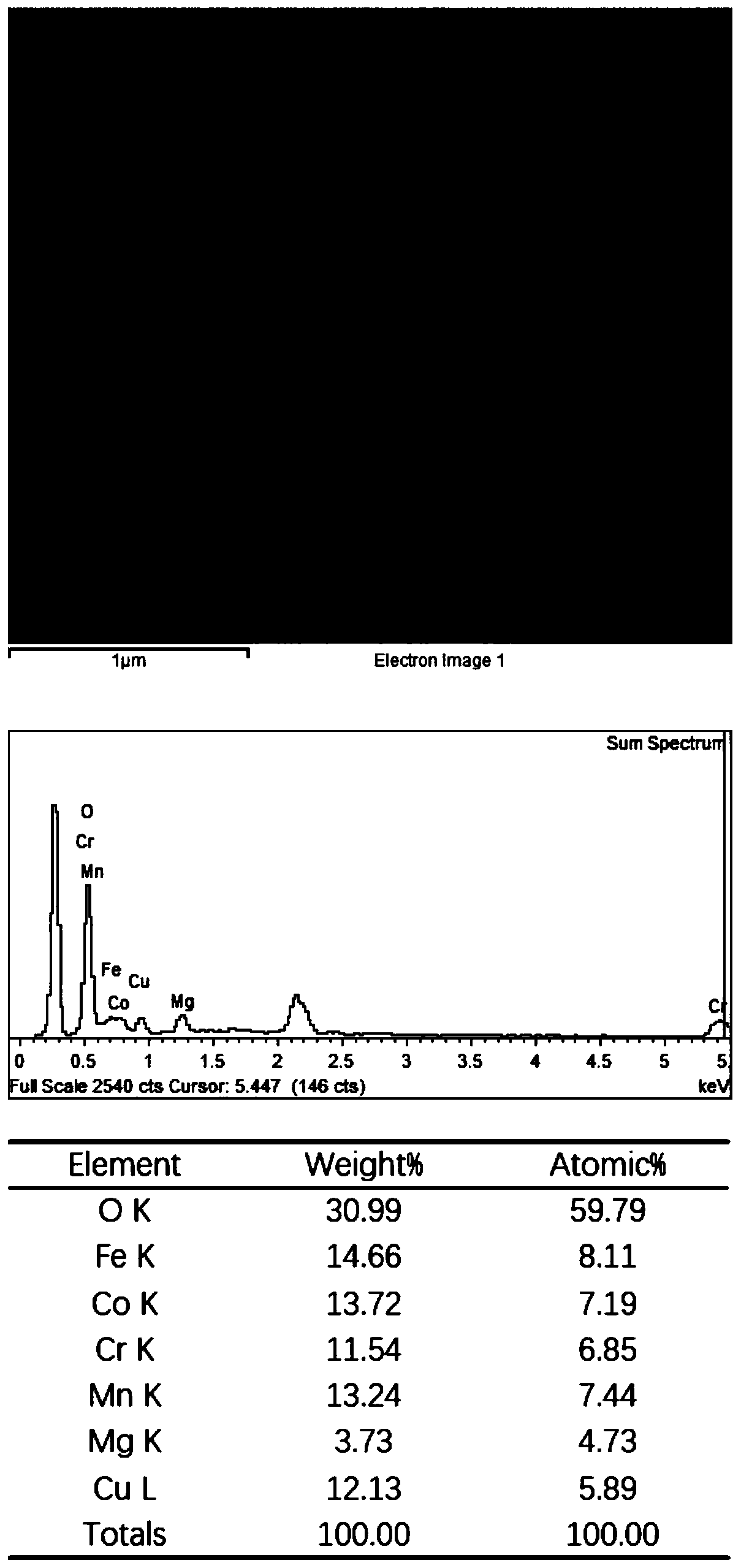

[0029] (1) Weigh Fe respectively according to molar ratio 1:1:1:2:1:1 2 o 3 (52.3g), Co 2 o 3 (54.3g), Cr 2 o 3 (49.8g), MnO 2 (61.9g), MgO (13.1g) and CuO (26.0g) powder, the powder after mixing is packed in the ball mill jar;

[0030] (2) According to the mass ratio of ball: material: water is 3:1:1, add ZrO respectively 2 Grinding balls and distilled water;

[0031] (3) Place the polyurethane ball milling pot milling on the pot milling machine station, and continuously ball milling at 220r / min for 12 hours to obtain mixed powder;

[0032] (4) The ball-milled powder is dried and sieved.

[0033] Step 2, calcining:

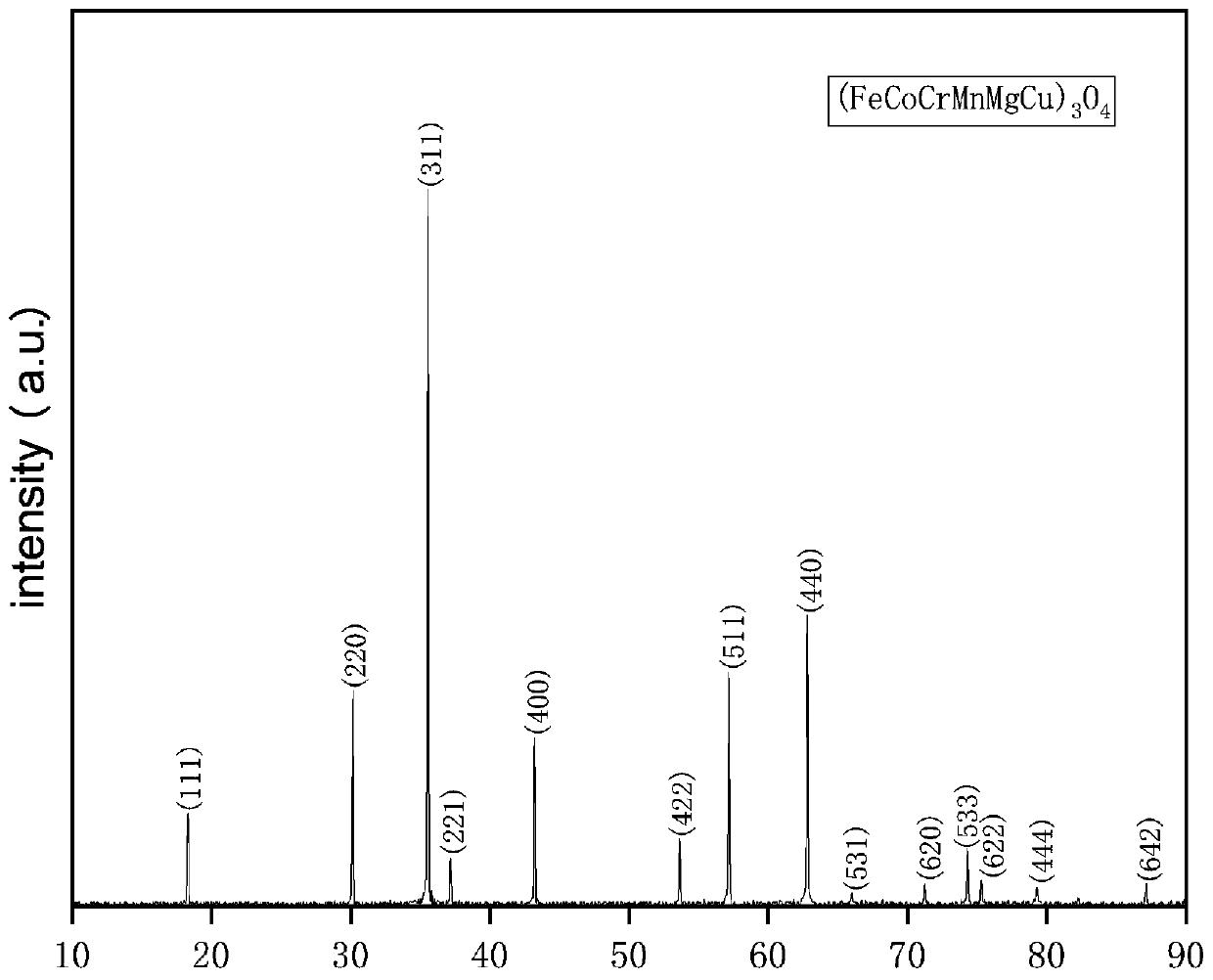

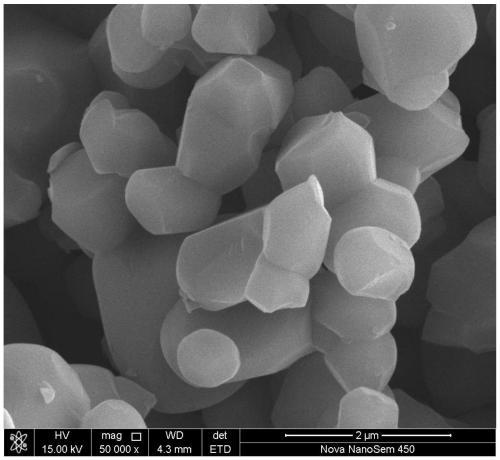

[0034] The sieved mixed powder is calcined in a muffle furnace and heated to 1000 ° C for 1 hour, and the furnace is cooled to room temperature after cal...

Embodiment 2

[0040] A method for preparing a six-element spinel-type iron-cobalt-chromium-manganese-magnesium-copper-based high-entropy oxide and its powder, comprising the following steps:

[0041] Step 1, mix:

[0042] (1) Weigh Fe respectively according to molar ratio 1:1:1:2:1:1 2 o 3 (52.3g), Co 2 o 3 (54.3g), Cr 2 o 3 (49.8g), MnO 2 (61.9g), MgO (13.1g) and CuO (26.0g) powder, the powder after mixing is packed in the ball mill jar;

[0043] (2) According to the mass ratio of ball: material: water is 3:1:1, add ZrO respectively 2 Grinding balls and distilled water;

[0044] (3) Place the polyurethane ball milling pot milling on the pot milling machine station, and continuously ball milling at 220r / min for 12 hours to obtain mixed powder;

[0045] (4) The ball-milled powder is dried and sieved.

[0046] Step 2, calcining:

[0047] The sieved mixed powder is calcined in a muffle furnace and heated to 900 ° C for 2 hours, and the furnace is cooled to room temperature after cal...

Embodiment 3

[0049] A method for preparing a six-element spinel-type iron-cobalt-chromium-manganese-magnesium-copper-based high-entropy oxide and its powder, comprising the following steps:

[0050] Step 1, mix:

[0051] (1) Weigh Fe respectively according to molar ratio 1:1:1:2:1:1 2 o 3 (52.3g), Co 2 o 3 (54.3g), Cr 2 o 3 (49.8g), MnO 2 (61.9g), MgO (13.1g) and CuO (26.0g) powder, the powder after mixing is packed in the ball mill jar;

[0052] (2) According to the mass ratio of ball: material: water is 3:1:1, add ZrO respectively 2 Grinding balls and distilled water;

[0053] (3) Place the polyurethane ball milling pot milling on the pot milling machine station, and continuously ball milling at 220r / min for 12 hours to obtain mixed powder;

[0054] (4) The ball-milled powder is dried and sieved.

[0055] Step 2, calcining:

[0056] The sieved mixed powder is calcined in a muffle furnace and heated to 800 ° C for 3 hours, and the furnace is cooled to room temperature after cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com