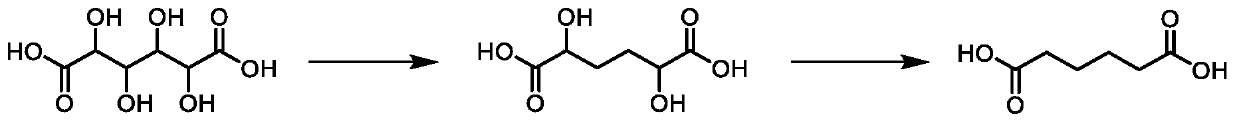

Method for preparing adipic acid and 2, 5-dihydroxy adipic acid from hexaldehyde saccharic acid

A technology of aldoglucaric acid and hydroxyadipic acid, which is applied in the preparation of carboxylate, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of environmental pollution, high cost, and non-green production process, and achieve Environmental friendliness and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] 1. TiO 2 Preparation of supported Pd catalyst

[0037] With 1%Pd / TiO 2 The preparation of the catalyst is used as an example for non-limiting illustration.

[0038] 560mg of 10wt% Pd(NH 3 ) 4 (NO 3 ) 2 Mix the aqueous solution with 20mL deionized water, add 2g TiO 2 The carrier was stirred at room temperature for 8 hours, the solvent was evaporated to dryness by a rotary evaporator, and then dried in an oven at 120° C. for 10 hours. Calcined in air at 400°C for 3h, then in 20%H 2 +N 2 Reduction at 300℃ for 1h to get 1%Pd / TiO 2 catalyst. The loading amount of Pd is 1% (mass percentage).

[0039] 2. TiO2 2 Loaded MoO 3 Catalyst preparation

[0040] With 15% MoO 3 / TiO 2 The preparation of the catalyst is used as an example for non-limiting illustration.

[0041] Mix 552mg ammonium heptamolybdate and 20mL deionized water, add 2g TiO 2 The carrier was stirred at room temperature for 8 hours, the solvent was evaporated to dryness by a rotary evaporator, and...

Embodiment 1

[0048] Embodiment 1, prepare 2,5-dihydroxyadipic acid by glucaric acid in aqueous solution

[0049] In a 50mL autoclave, add 0.2g of 1%Pd / TiO 2 Catalyst and 15mL mass percentage content are 2% glucaric acid aqueous solution, after reaction kettle is airtight, be filled with 2MPa hydrogen gas scrubbing three times, in the reaction kettle, be filled with 2MPa hydrogen gas, put reaction kettle on heating furnace and be heated to The reaction temperature was 150° C., and the reaction was stirred for 8 hours at a rotation speed of 600 rpm. After the reaction was completed, the mixture was cooled down to room temperature in an ice-water bath, and filtered under reduced pressure. The filtrate was 2,5-dihydroxyadipic acid with a yield of 93%.

Embodiment 2

[0050] Embodiment 2, prepare 2,5-dihydroxyadipic acid by galactaric acid in aqueous solution

[0051] In a 50mL autoclave, add 0.2g of 1%Pd / TiO 2 Catalyst and 15mL of galactaric acid aqueous solution with a mass percentage of 2%. After the reactor is sealed, fill it with 2MPa hydrogen to scrub three times, then fill the reactor with 2MPa hydrogen, and place the reactor on a heating furnace for heating To the reaction temperature of 150° C., the reaction was stirred at 600 rpm for 8 h. After the reaction was completed, the mixture was cooled down to room temperature in an ice-water bath, and filtered under reduced pressure. The filtrate was 2,5-dihydroxyadipic acid with a yield of 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com