Mountain energy-saving sunlight greenhouse wall and manufacturing method thereof

A technology for a solar greenhouse and a manufacturing method, applied in greenhouse cultivation, botanical equipment and methods, walls, etc., can solve the problems of high cost, short service life, complicated construction process, etc., and achieve excellent stability and durability, excellent mechanics performance, the effect of promoting promotion and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

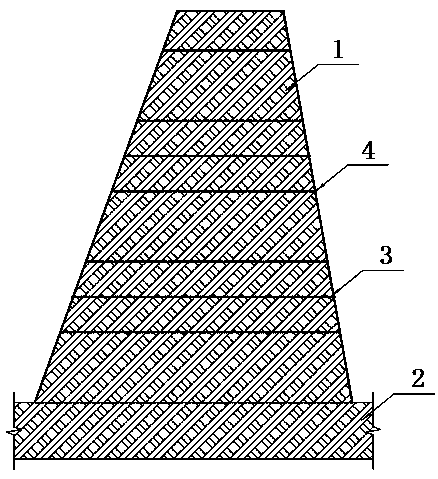

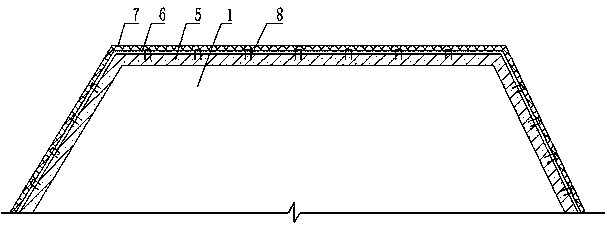

[0031] A mountain energy-saving solar greenhouse wall, comprising a wall foundation 2 and a wall 1, the wall foundation 2 is located at the bottom of the wall 1, and the wall foundation 2 is wider than the bottom of the wall 1 by more than 300mm.

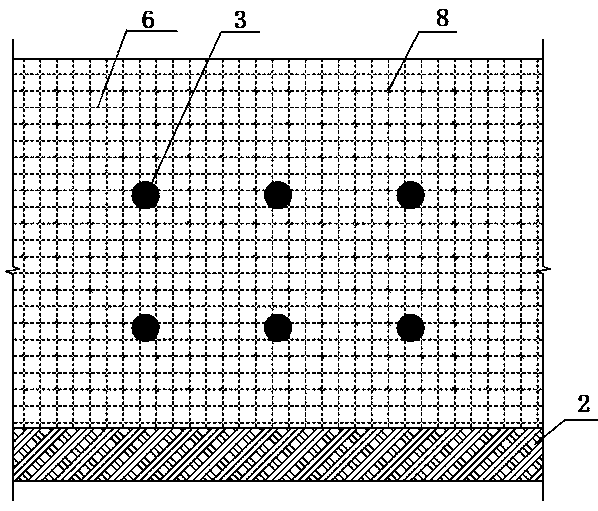

[0032] The wall 1 has a trapezoidal structure, and a plurality of geogrids 3 and anchor rods 4 are arranged in the wall, a consolidation layer 5 is arranged on the surface of the wall, and a steel wire mesh 6 and a cement mortar surface layer 7 are arranged outside the consolidation layer 5 , the steel wire mesh 6 is connected to the consolidation layer 5 and embedded in the cement mortar surface layer 7 . Steel mesh is fixed with U-shaped anchor bar 8.

[0033] Geogrid 3 is made of glass fiber geogrid, the grid size is 25.4×25.4mm, and the interval between multiple geogrids is 1 meter. Multi-layer geogrids are laid from bottom to top. When laying each layer of geogrids, adjacent pieces are lapped. The lap width is not less than 15...

Embodiment 2

[0046] Aiming at mountain conditions, multiple greenhouses are arranged in front and back. The consolidation material sprayed on the outside of the back wall of the greenhouse is W-OHC solution with a mass concentration of 10-15%. The penetration depth of the consolidation material solution into the wall is 5-8cm; steel wire mesh The strength of the cement mortar sprayed on the outer surface is not less than M5, and the thickness is greater than 10mm. Also mixed with quartz powder and cellulose ether in the cement mortar, according to parts by weight, for every 100 parts of cement, add 60-80 parts of quartz powder and 0.05-0.5 part of cellulose ether to enhance the strength and toughness of the cement mortar. The firmness of the outer side of the rear wall is enhanced.

Embodiment 3

[0048] For areas with many rodents, when making the wall foundation of the greenhouse, double-layer steel wire mesh is inserted longitudinally in the foundation, and the insertion depth of the steel mesh is more than 50 cm from the upper surface of the foundation to prevent rodents from damaging the greenhouse wall. And it can prevent the influence of mountain tree root growth on the greenhouse wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com