Method for manufacturing glass-based buried spot-size converter through temperature gradient ion diffusion of grooved hot plate

A mode spot converter and ion diffusion technology, which is applied in the field of optical devices and integrated optics, to achieve the effects of reduced device insertion loss, improved matching degree, optimized structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

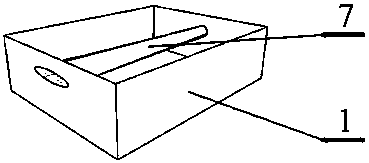

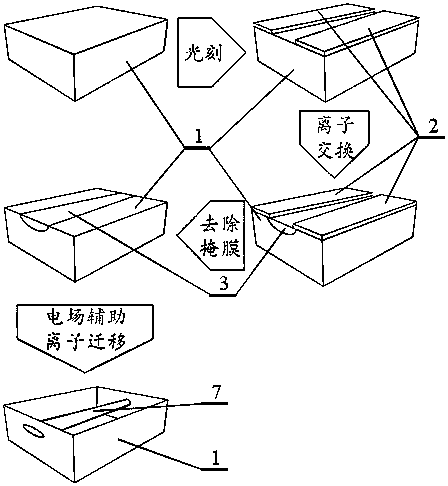

[0024] Embodiment 1: slowly changing Ag + / Na + Ion-exchange glass-based buried mode spot converter

[0025] Required equipment and materials: double-sided polished BK7 glass substrate with a thickness of 1 mm (1), cleaning equipment and lotion, sputtering coating equipment, strip waveguide mask (line width 3-5 microns), photolithography equipment, Corrosion equipment, acetone, beaker, high temperature furnace, chip end face grinding and polishing equipment, quartz crucible, quartz flower basket, hot plate with groove (5) (groove length 8.0mm, width 2.5mm, depth 5.0mm), doping ion is Ag + , the molten salt containing dopant ions is Ca(NO 3 ) 2 、NaNO 3 and AgNO3 mixed molten salt (the molar ratio of the three is 49:49:2, and the dopant ion is Ag + ).

[0026] The main steps are as follows:

[0027] (A) Fabrication of the glass substrate (1) to bury the strip-shaped ion-doped region (8)

[0028] Main steps: cleaning the glass substrate (1); sputtering an aluminum film wi...

Embodiment 2

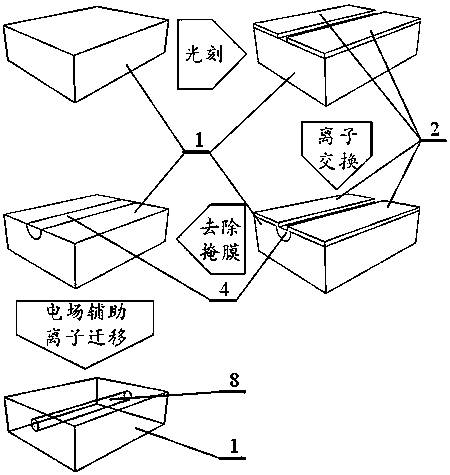

[0037] Example 2: Compact Ag + / Na + Ion-exchange glass-based buried mode spot converter

[0038] Required equipment and materials: double-sided polished BK7 glass substrate with a thickness of 1 mm (1), cleaning equipment and lotion, sputtering coating equipment, strip waveguide mask (line width 3-5 microns), photolithography equipment, Corrosion equipment, acetone, beaker, high temperature furnace, chip end face grinding and polishing equipment, quartz crucible, quartz flower basket, hot plate with groove (5) (groove length 8.0mm, width 2.5mm, depth 1.5mm), doped ion is Ag + , the molten salt containing dopant ions is Ca(NO 3 ) 2 、NaNO 3 and AgNO3 mixed molten salt (the molar ratio of the three is 49:49:2, and the dopant ion is Ag + ).

[0039] The main steps are as follows:

[0040] (A) Fabrication of the glass substrate (1) to bury the strip-shaped ion-doped region (8)

[0041] Main steps: cleaning the glass substrate (1); sputtering an aluminum film with a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com