Metal oxide composite self-supporting heat-conducting carbon film, metal lithium negative electrode and preparation and application of metal oxide composite self-supporting heat-conducting carbon film

A self-supporting, oxide-based technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve problems such as complex processes and poor lithium affinity, achieve adjustable porosity, reduce current density, and improve long-term cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

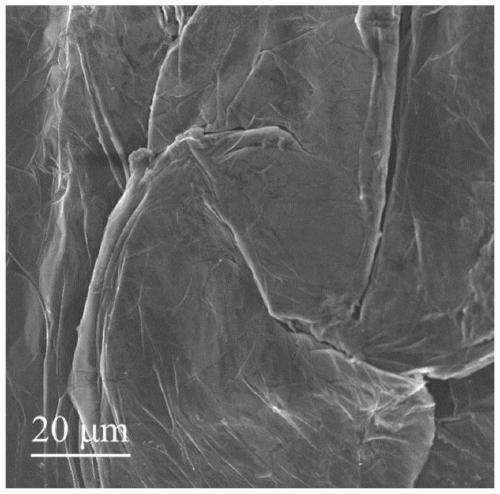

[0066] A heat-conducting carbon film is obtained by mixing polymer polyimide with graphene after carbonization at 800°C for 2 hours and pressing it in a hot roller press to form a film. The film forming pressure is 6MPa and the rolling speed is 1.0m. / min, the temperature is 400°C; the obtained thermally conductive carbon film (see SEM picture figure 1 ; film-forming structure, and there are certain wrinkles on the surface), it is cut into a disc with a diameter of 13mm for later use. Weigh 2.39g of zinc nitrate hexahydrate Zn(NO3)2·6H2O and dissolve in 100mL of anhydrous methanol to form a colorless solution A; weigh 4.69g of 2-methylimidazole and 1g of the modified carbon film, and dissolve them in 100mL Solution B was configured in anhydrous methanol. Secondly, under the condition of magnetic stirring, with the help of a separatory funnel, will contain a large amount of Zn 2+ The solution A was added dropwise to the solution B containing a large amount of organic ligands ...

Embodiment 2

[0068] Compared with Example 1, the only difference is that the charging and discharging system is changed. The result is: at 1mA / cm 2 current density and 3mAh / cm 2 Under the area capacity, the average Coulombic efficiency reaches 98.1%, and the stable cycle is more than 210 cycles.

Embodiment 3

[0070] Compared with Example 1, the only difference is that the film-forming pressure is changed to 10MPa, and the electrochemical performance is measured by the method of Example 1. The result is: the average Coulombic efficiency is 98.1%, and it can cycle stably for more than 370 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com