Reverse electrodialysis reactor, wastewater treatment device and application thereof

A technology for reverse electrodialysis and wastewater treatment, applied in the field of electrochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

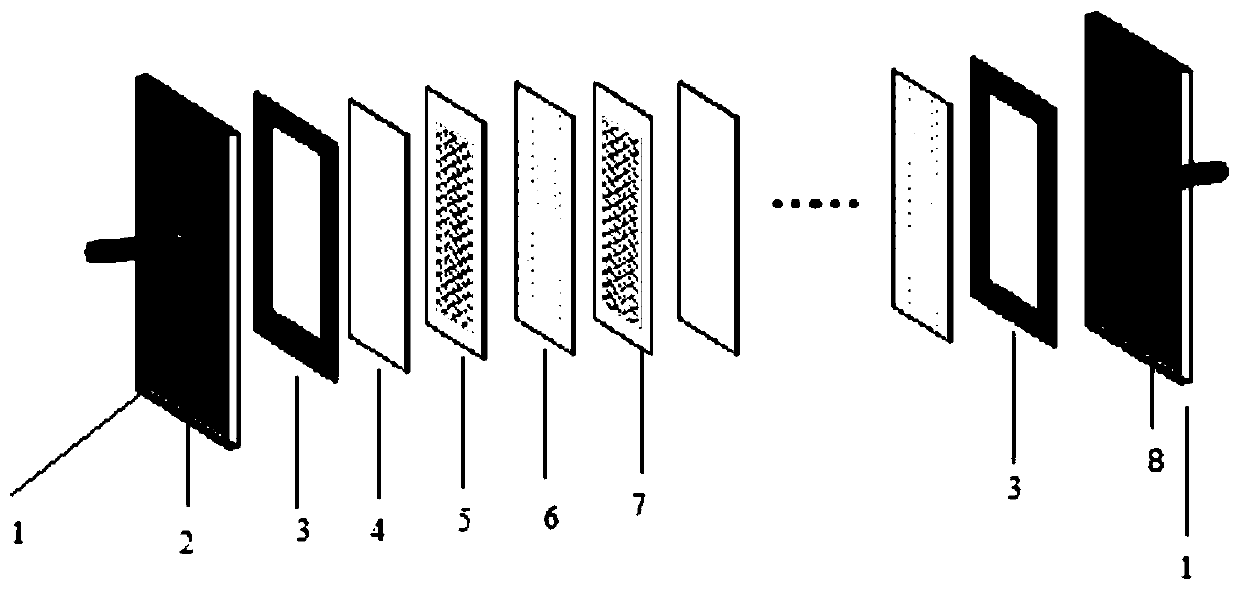

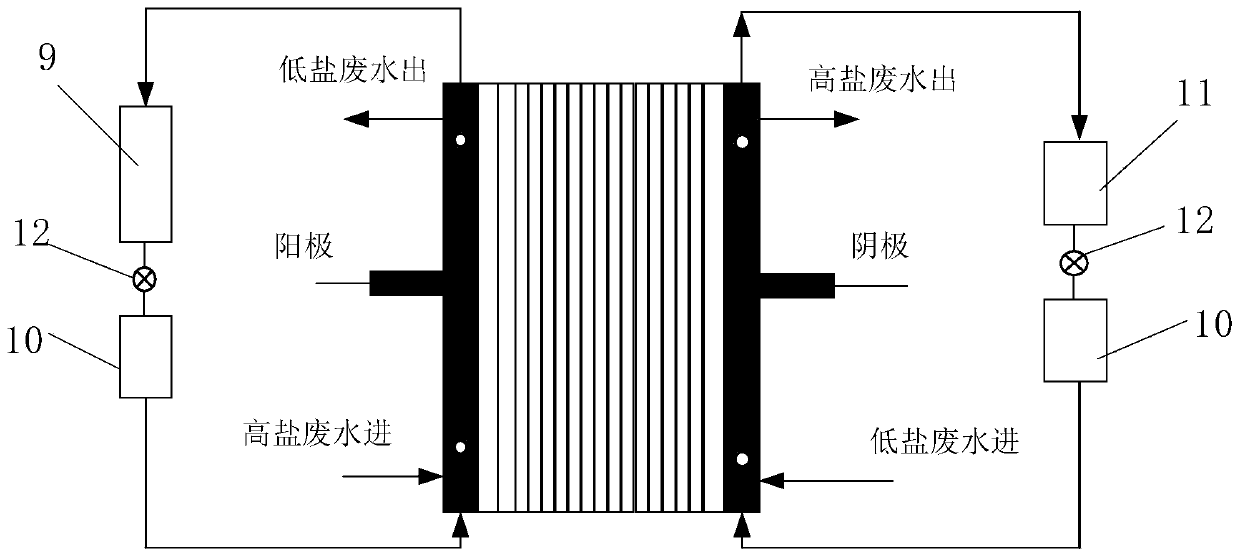

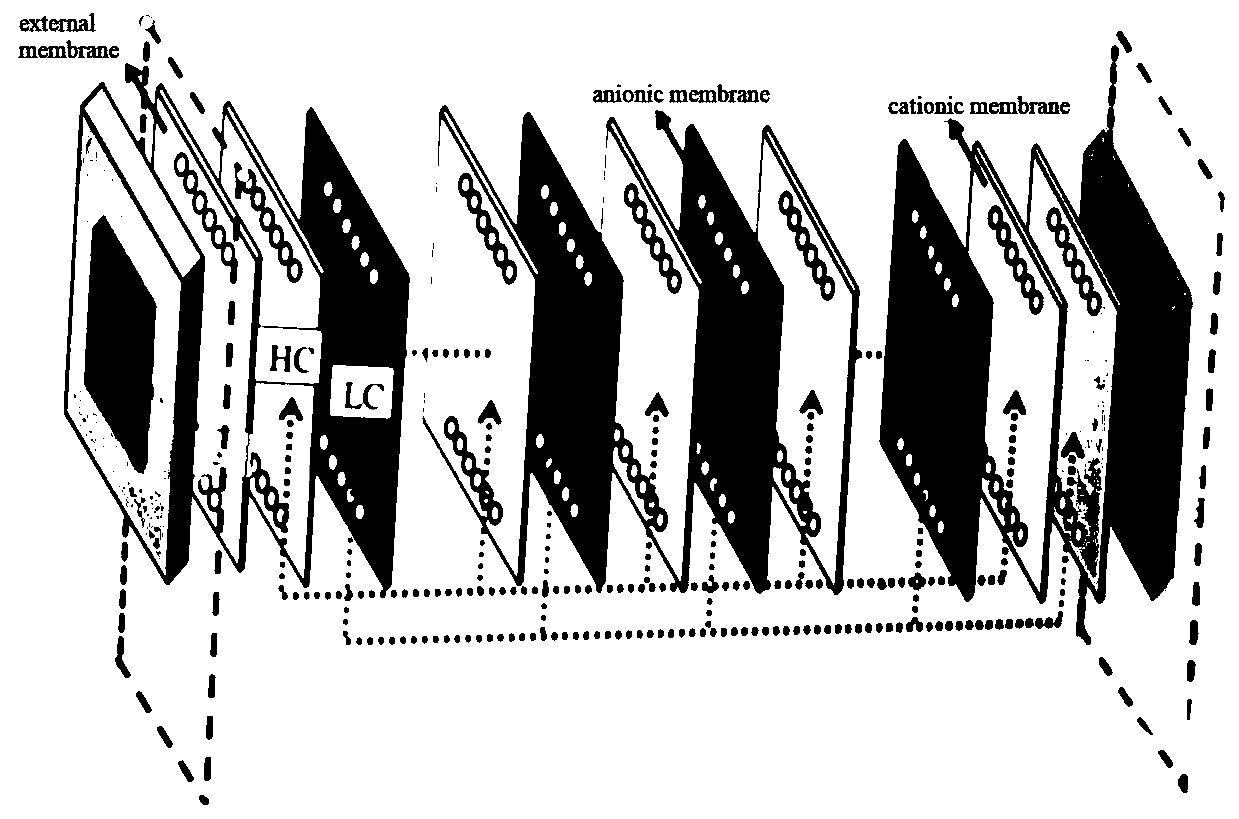

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Wastewater treatment of a pesticide enterprise:

[0045] A certain chlorfenapyr production wastewater discharged from different production sections contained the highest sodium chloride 131.89g / L, and the corresponding COD content was 215392mg / L. The minimum sodium chloride content is 12.25g / L, and the corresponding COD content is 130048mg / L. The organic wastewater containing high and low salt is introduced into the self-made electrolysis reactor equipped with titanium-based iridium dioxide-coated DSA anode plate, carbon felt cathode plate and 60 sets of anion and cation exchange membranes. The flow rate of each peristaltic pump is 200mL / min. The electrolyte is 200mL, and the current density is 1.8A / m continuously generated during the continuous reaction process 2 , The reaction runs for 4 hours to measure the COD content of the wastewater in the cathode and anode chambers, and replace 200mL of the original wastewater. The reaction can continuously obtain a...

Embodiment 2

[0046] Embodiment 2: Treatment of certain dichloronicotinic acid wastewater

[0047] The dichloronicotinic acid wastewater of an enterprise contains 165.96g / l of sodium chloride and 26500mg / l of COD. This wastewater is introduced into the above-mentioned introduction as high-salt wastewater. Equipped with titanium-based iridium dioxide-plated DSA anode plate, carbon felt cathode plate and 60 groups of anion and cation exchange membranes in a self-made reactor. The enterprise's production reuse water is used as low-salt wastewater, and its sodium chloride content is 2.5g / L. The flow rate of each peristaltic pump is 200mL / min. The cathode and anode chamber electrolyte is 200mL, and the current density is continuously generated at 2.3A / m during the continuous reaction process 2 , The reaction runs for 3 hours to measure the COD content of the wastewater in the cathode and anode chambers, and replace 200mL of the original wastewater. The reaction can continue to obtain about 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com