Imidazole-containing chemical silver plating wastewater treatment system and method thereof

A technology of chemical silver plating and treatment method, which is applied in metallurgical wastewater treatment, chemical instruments and methods, special compound water treatment, etc. It can solve the problems of high treatment cost, unreachable, membrane damage, etc., and achieve simple process equipment and automatic control Strong performance and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

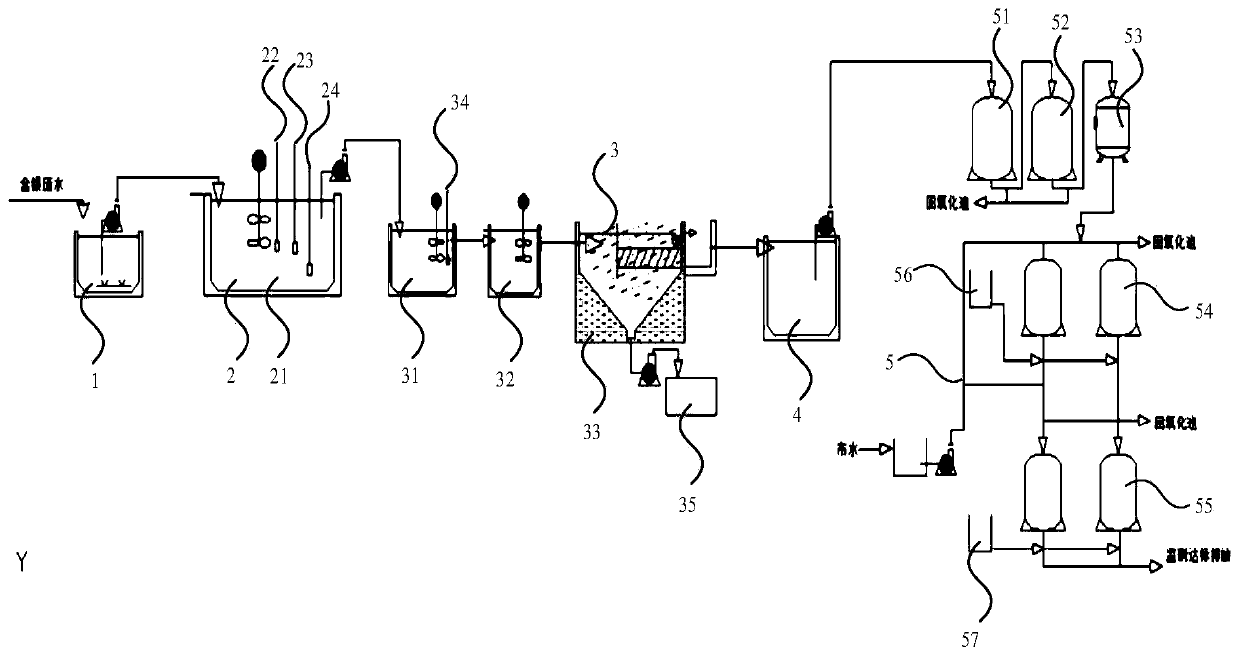

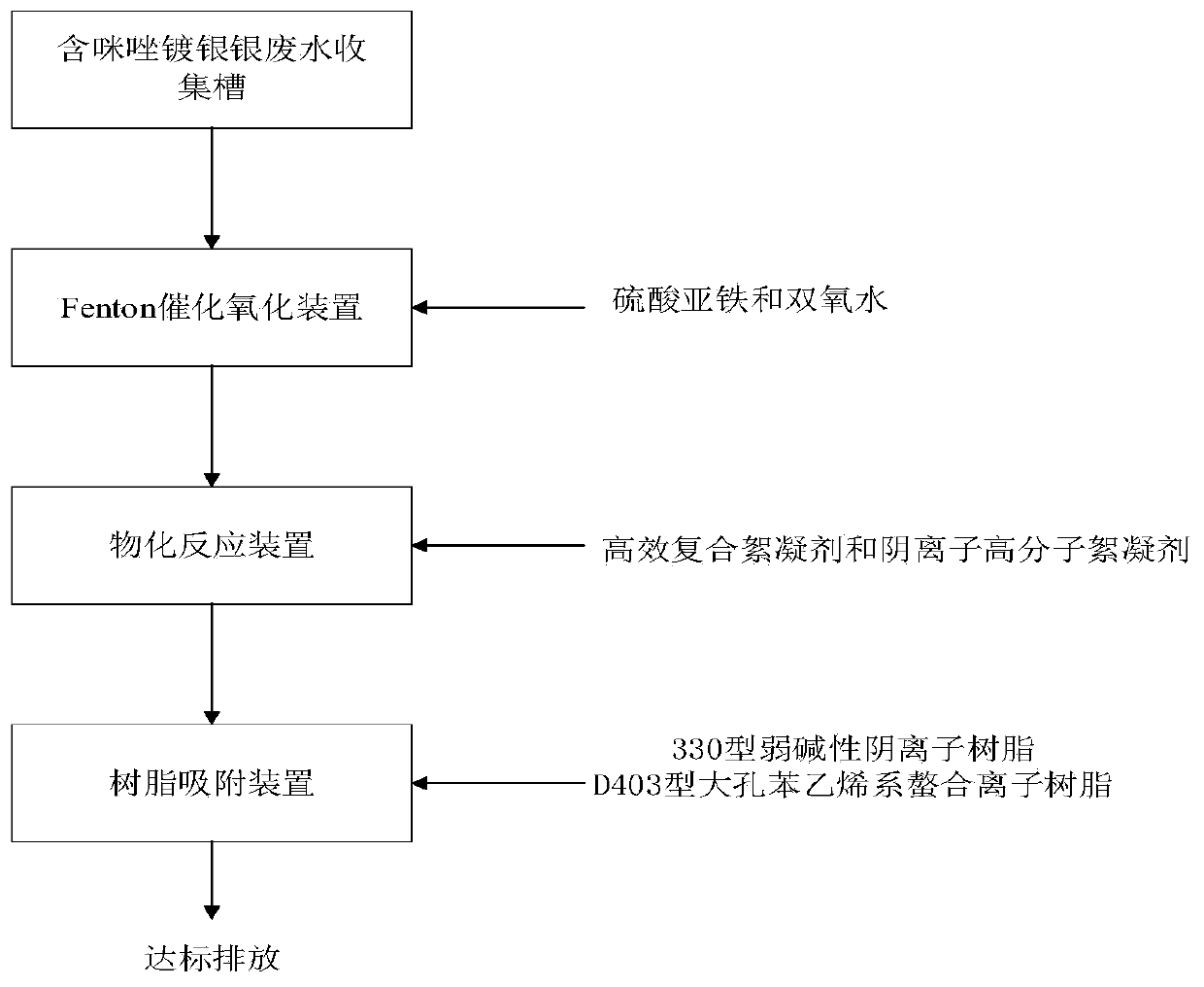

Method used

Image

Examples

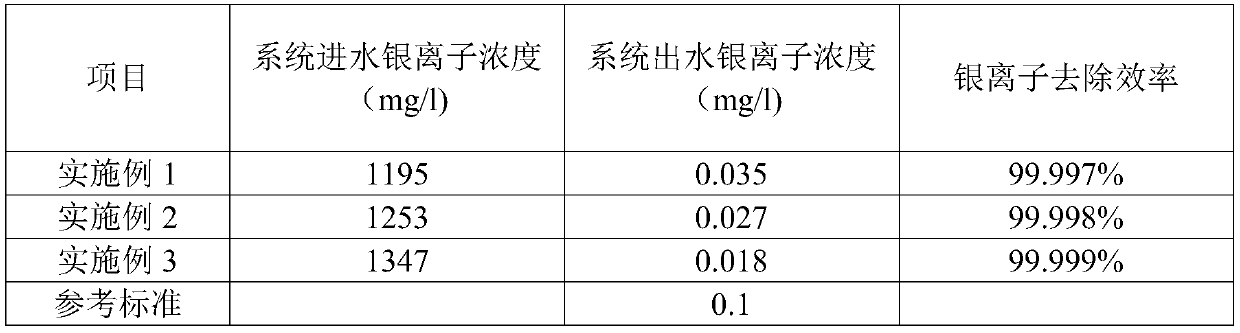

Embodiment 1

[0051] Embodiment 1 of the present invention provides a kind of processing method that adopts above-mentioned system to process the chemical silver-plating waste water containing imidazole, comprises the steps:

[0052] (1) Promote imidazole-containing chemical silver-plating wastewater from the collection tank to the oxidation pond of the Fenton catalytic oxidation device by pumping, add sulfuric acid or liquid caustic soda to the oxidation pond by the pH regulator, and adjust the pH of the mixed solution in the oxidation pond to 3.5, add ferrous sulfate again in the oxidation tank, the addition is 1% of the weight of the imidazole-containing chemical silver-plating wastewater, fully stir for 10min after adding, then add hydrogen peroxide in the oxidation tank, the addition is the weight of the imidazole-containing chemical silver-plating wastewater After fully stirring and reacting for 30 minutes, pass steam into the oxidation tank to heat up the oxidation tank until the temp...

Embodiment 2

[0056] Embodiment 2 of the present invention provides a kind of treatment method that adopts above-mentioned system to process the chemical silver-plating waste water containing imidazole, comprises the steps:

[0057] (1) Promote imidazole-containing chemical silver-plating wastewater from the collection tank to the oxidation pond of the Fenton catalytic oxidation device by pumping, add sulfuric acid or liquid caustic soda to the oxidation pond by the pH regulator, and adjust the pH of the mixed solution in the oxidation pond to 4. Add ferrous sulfate to the oxidation pond again, the addition is 3% of the weight of the imidazole-containing chemical silver-plating wastewater, fully stir for 10min after adding, then add hydrogen peroxide in the oxidation pond, the addition is the weight of the imidazole-containing chemical silver-plating wastewater After fully stirring and reacting for 60 minutes, pass steam into the oxidation tank to heat up the oxidation tank until the tempera...

Embodiment 3

[0061] Embodiment 3 of the present invention provides a kind of processing method that adopts above-mentioned system to process the chemical silver-plating waste water containing imidazole, comprises the steps:

[0062] (1) Promote imidazole-containing chemical silver-plating wastewater from the collection tank to the oxidation pond of the Fenton catalytic oxidation device by pumping, add sulfuric acid or liquid caustic soda to the oxidation pond by the pH regulator, and adjust the pH of the mixed solution in the oxidation pond to 5. Add ferrous sulfate to the oxidation pond again, the addition is 5% of the weight of the imidazole-containing chemical silver-plating wastewater, fully stir for 10 minutes after adding, then add hydrogen peroxide in the oxidation pond, the addition is the weight of the imidazole-containing chemical silver-plating wastewater After fully stirring and reacting for 120 minutes, pass steam into the oxidation tank to heat up the oxidation tank until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com