Silicone rubber for low-compression-set rubber roller and preparation method thereof

A permanent deformation and low compression technology, which is applied in the field of silicone rubber for low compression permanent deformation rubber rollers and its preparation, can solve the problems of poor heat resistance, high compression set rate, and poor compression set rate, and achieve excellent mechanical properties , The effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

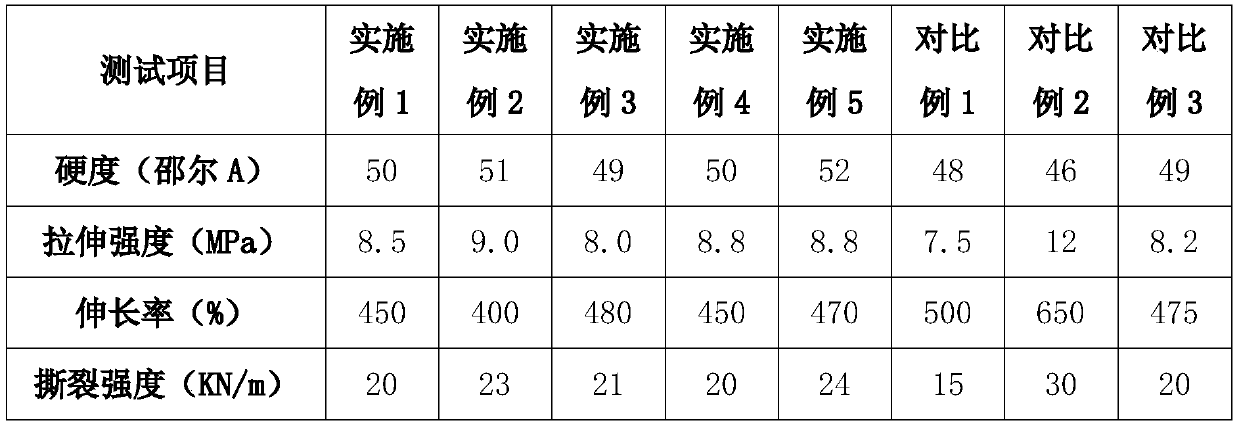

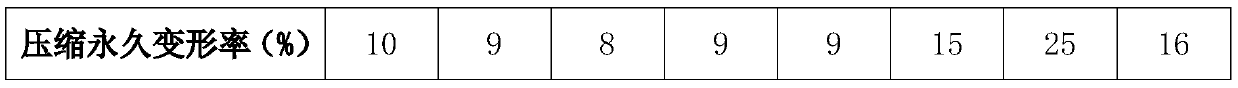

Examples

Embodiment 1

[0076] Each raw material composition is as follows:

[0077] 50 parts of methyl vinyl silicone rubber with a molar mass of 600,000 g / mol and a vinyl content of 0.16%, 50 parts of methyl vinyl silicone rubber with a molar mass of 600,000 g / mol and a vinyl content of 0.22% 50 parts of glue, BET method specific area is 200m 2 35 parts of fumed silica per g, 55 parts of silicon micropowder with a particle size of 1.5 μm, 2 parts of hexamethyldisilazane, 2 parts of dimethyldimethoxysilane, 1 part of deionized water, 1 part of nano-titanium dioxide with a particle size of 5nm, 1 part of nano-cerium oxide with a particle size of 7nm, 0.2 part of zinc stearate, 0.1 part of stearic acid, 2,5-dimethyl-2,5-di-tert-butyl peroxide 1.2 parts of hexane oxide.

[0078] The preparation method of silicone rubber is as follows:

[0079] A. Add all methyl vinyl silicone rubber raw rubber and part of white carbon black into the kneader, then pour hexamethyldisilazane, dimethyldimethoxysilane, d...

Embodiment 2

[0084] Each raw material composition is as follows:

[0085] 60 parts of methyl vinyl silicone rubber with a molar mass of 700,000 g / mol and a vinyl content of 0.15%, 60 parts of methyl vinyl silicone rubber with a molar mass of 500,000 g / mol and a vinyl content of 0.25% 40 parts of glue, the specific area of BET method is 150m 2 40 parts per gram of fumed silica, 50 parts of silicon micropowder with a particle size of 1 μm, 3 parts of hexamethyldisilazane, 3 parts of dimethyldimethoxysilane, 2 parts of deionized water, granules 0.5 parts of nano-titanium dioxide with a particle size of 7nm, 1.5 parts of nano-cerium dioxide with a particle size of 7nm, 0.2 parts of zinc stearate, 0.2 parts of stearic acid, 2,5-dimethyl-2,5-di-tert-butyl peroxide 1.0 parts of hexane oxide.

[0086] The preparation method of silicone rubber is the same as that of Example 1.

Embodiment 3

[0088] Each raw material composition is as follows:

[0089] 40 parts of methyl vinyl silicone rubber with a molar mass of 650,000 g / mol and a vinyl content of 0.18%, 40 parts of methyl vinyl silicone rubber with a molar mass of 550,000 g / mol and a vinyl content of 0.20% 60 parts of glue, BET method specific area is 380m 2 30 parts / g of fumed silica, 60 parts of silicon micropowder with a particle size of 2 μm, 1 part of hexamethyldisilazane, 1 part of dimethyldimethoxysilane, 1 part of deionized water, hard 0.1 part of zinc fatty acid, 0.1 part of stearic acid, and 0.8 part of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane.

[0090] The preparation method of silicone rubber is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com