High-toughness and high-temperature-resistant UV peelable adhesive and preparation method and application thereof

A high-temperature, high-toughness technology, used in adhesives, non-polymer adhesive additives, adhesive types, etc., can solve problems such as poor adhesive layer toughness, and achieve the effects of easy peeling, cost saving, and simple curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation of UV-curable peelable blue glue composition comprises the following steps:

[0042] The UV-curable blue glue composition of the present invention can be prepared by putting each raw material of the adhesive composition into the mixing tank sequentially according to the proportioning requirements, and stirring according to a certain speed and time. The preparation process is carried out under normal temperature and pressure, and needs to be protected from light.

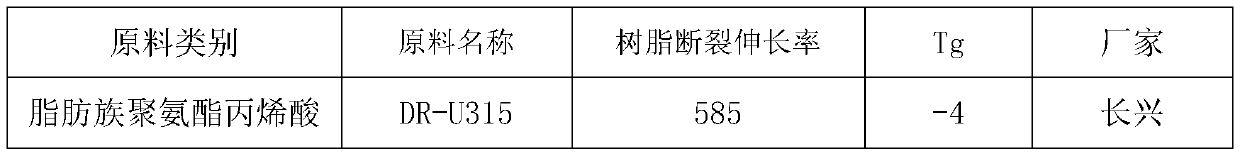

Embodiment 1

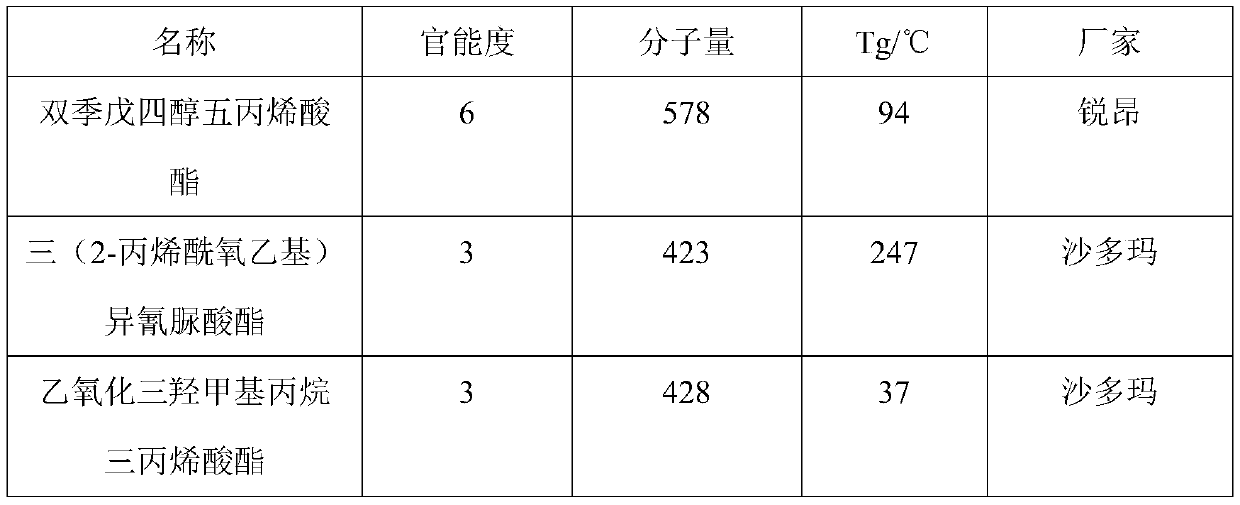

[0044] 1. Put 20g of aliphatic polyurethane acrylate oligomer DR-U315, 10g of hydroxyethyl acrylate, 40g of polyethylene glycol di(meth)acrylate (molecular weight 512) and 5g of sodium lauryl sulfate into the mixing tank Stirring in , the stirring speed was set at 1000rpm / min, and stirred for 20 minutes;

[0045] 2. Add 3g of 1-hydroxycyclohexyl phenyl ketone and 1g of 2,4,6-(trimethylbenzoyl) diphenylphosphine oxide, and 0.1g of 2,6-dibutyl-4- After methyl phenol is weighed, drop into stirring tank successively and stir, stirring speed is set as 1000rpm / min, and stirring time is 30 minutes;

[0046] 3. Filter and package the mixture in the mixing tank to obtain UV peelable adhesive with high toughness and high temperature resistance; the product performance test data are shown in Table 3.

Embodiment 2

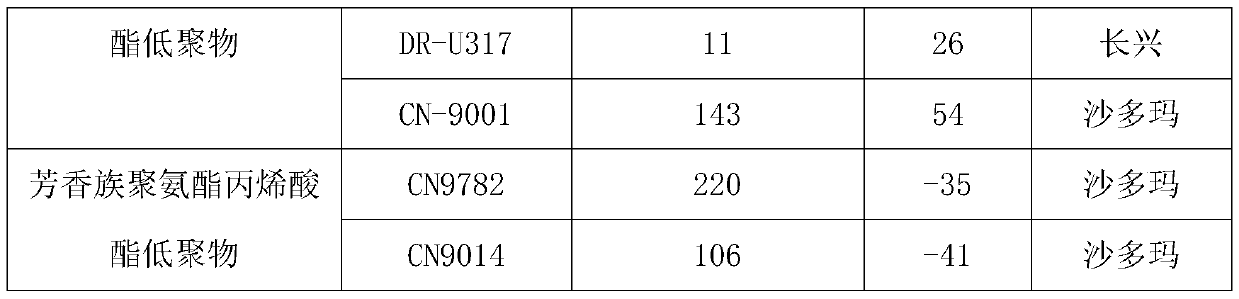

[0048] 1. Put 25g aromatic polyurethane acrylate oligomer CN9782, 30g isocylacrylate, 20g amino-modified polyethylene glycol acrylate, 20g ethoxylated bisphenol A (meth)acrylate and 8g alkyl polyether After weighing, put it into the mixing tank and stir, the stirring speed was set at 900rpm / min, and stirred for 20 minutes;

[0049] 2. After weighing 4g of 1-hydroxycyclohexyl phenyl ketone, 1g of 2,4,6-(trimethylbenzoyl) diphenylphosphine oxide and 0.1g of tris(hexadecanyl alcohol) ester, Put it into the mixing tank and stir, the stirring speed is set to 1200rpm / min, and the stirring time is 40 minutes;

[0050] 3. Weigh 0.5g of blue pigment VP3491, 0.5g of dispersant BYK2008, and 0.2g of leveling agent, put them into the mixing tank, set the stirring speed at 1200rpm / min, and stir for 35 minutes;

[0051] 4. Filter and package the mixture in the mixing tank to obtain UV peelable adhesive with high toughness and high temperature resistance; the product performance test data ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com