Preparation method and application of phospholipid-coated polyacrylic acid/zinc phosphate nanoparticles

A technology of polyacrylic acid and zinc phosphate, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulations, etc., to achieve the effects of stable structure, high drug loading, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: Preparation of zinc phosphate nanoparticles

[0068] In a 100 mL round bottom flask, 5.0 mg of ZnO white powder and 20 mg of polyacrylic acid were sequentially added to 10 mL of deionized water, then stirred at 25°C for 30 min until the solution was transparent. With stirring, slowly add 10 mL of isopropanol dropwise to the clear solution. Then 14.67mg Na 2 HPO 4 12H 2 O was added to the above reaction solution, and after 4 hours of reaction, the solution was transferred to a 25mL hydrothermal reactor, placed in an oven at 120°C for 30 minutes, cooled to room temperature naturally, centrifuged (8000r / min, 8min), and deionized Water was washed several times to obtain PAA / ZnP nanoparticles.

Embodiment 2

[0069] Example 2: Characterization of zinc phosphate nanoparticles

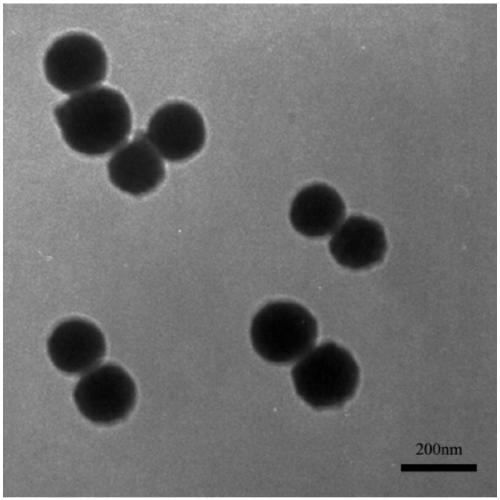

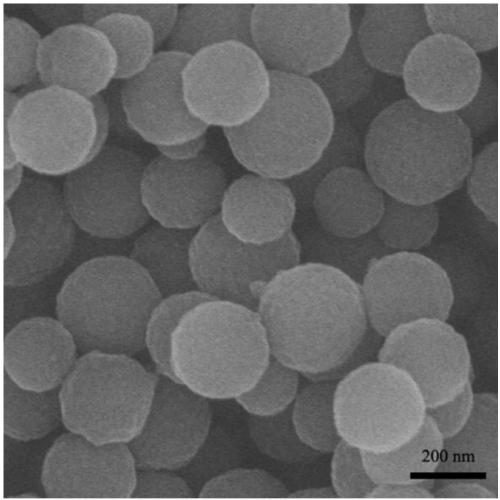

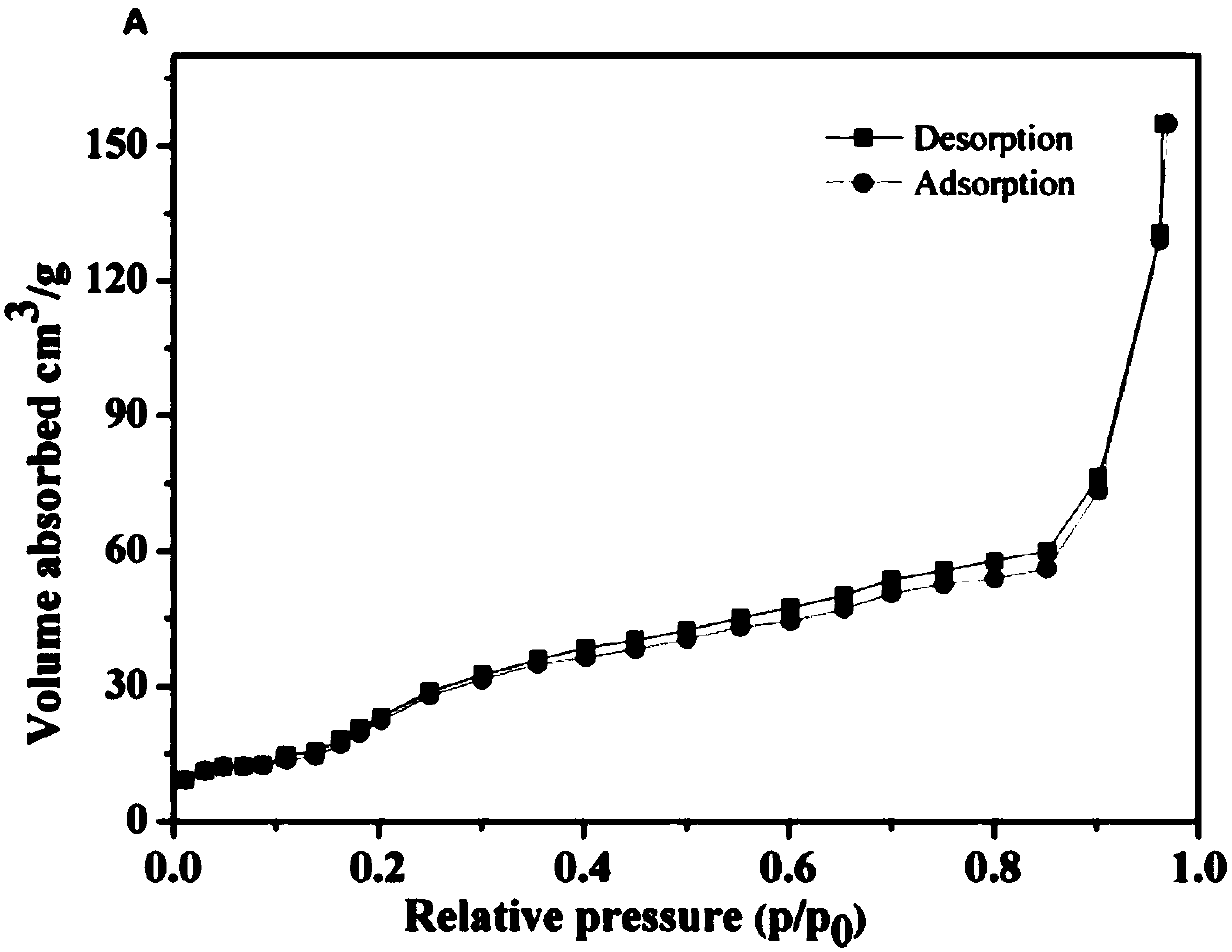

[0070] The morphology of PAA / ZnP NPs was observed by transmission electron microscopy, and the results were as follows: figure 1 shown; using scanning electron microscope to observe the surface characteristics of PAA / ZnP NPs nanoparticles, the results are as follows figure 2 shown. TEM and SEM results showed that PAA / ZnP NPs were spherical nanoparticles with rough appearance and uniform particle size. The particle size measured by laser particle size method is 165nm. The nitrogen adsorption and pore size results of PAA / ZnP NPs are as follows image 3 , 4 As shown, its specific surface area is 167.24m 2 / g, the pore volume is 0.32cm 3 / g, the average pore size is 2.67nm, with large surface area, pore volume and wide pore size distribution suitable for drug carriers. Using TEM to observe the morphology of PAA / ZnP NPs in different PBS (pH 5.0 and pH 7.4), the results are as follows Figure 5 shown. The...

Embodiment 3

[0071] Embodiment 3: compared with embodiment 1, the consumption of ZnO white powder is changed into 10.0mg, and stirring time is changed into 45min, and the consumption of isopropanol is changed into 30ml, Na 2 HPO 4 12H 2 The amount of O was changed to 44.8 mg, and other reaction conditions were unchanged. The specific surface area of the obtained PAA / ZnP nanoparticles is 167.24m 2 / g, the pore volume is 0.32cm 3 / g, the average pore size is 2.67nm, with large surface area, pore volume and wide pore size distribution suitable for drug carriers. The particle size measured by laser particle size method is 165nm, and its specific surface area is 220m 2 g -1 , the pore volume is 0.55cm 3 g -1 , the pore size distribution is 4.5nm, with a wide pore size distribution, which can realize the loading and release of drugs, and can meet the requirements of drug loading.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com