Comfortable fabric with moisture-absorbing, uniform-heating and warm-keeping structure and weaving method of comfortable fabric

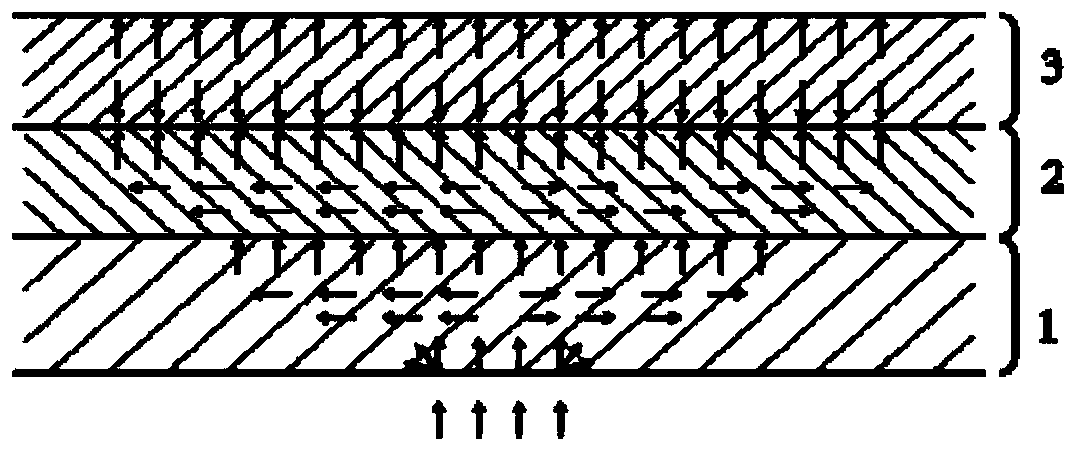

A technology of comfort and fabrics, applied in textiles and papermaking, chemical instruments and methods, textiles, etc., can solve the problems of difficult moisture absorption and heating effects of fabrics, concentrated heat generation in sweating parts, and does not consider uneven distribution of sweat, etc., to achieve effective Facilitate rapid diffusion and outward transfer, promote the effect of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

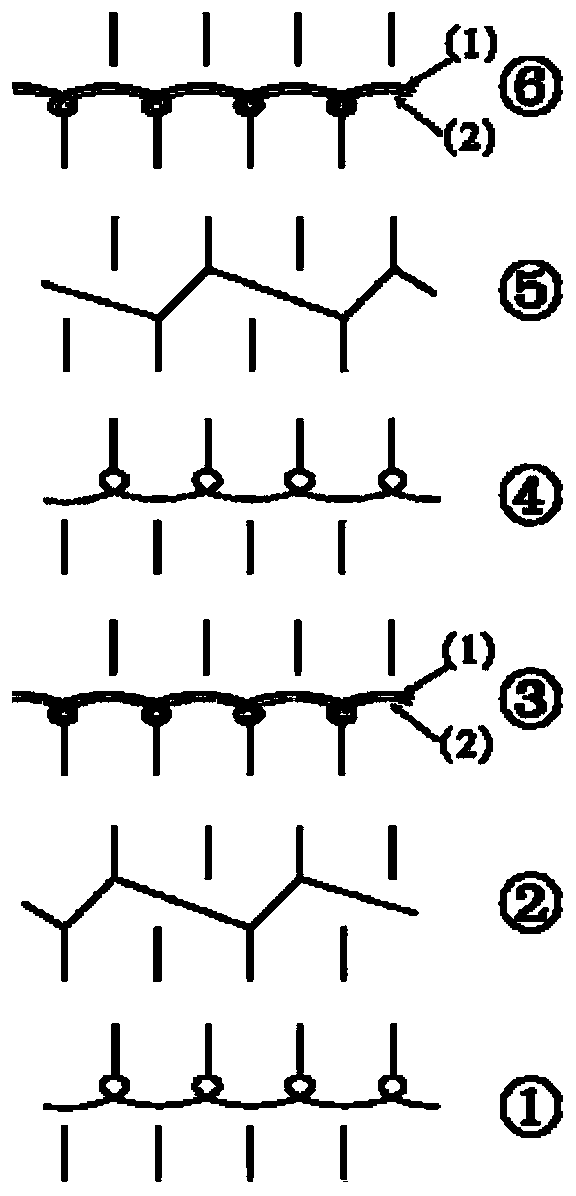

[0055] A method for weaving a comfortable fabric with a moisture-absorbing uniform heat-retaining structure, the steps of which are as follows:

[0056] Raw material preparation: the first yarn is cross-section polyester DTY filament, the specification is 150D / 144F; the second yarn is EKS fiber and viscose fiber Siro compact blended yarn, the blending ratio is 40 / 60, and the specification is 32 pounds, among which EKS fiber is developed by Japan Toyobo, a compound made of acrylic acid, acrylate, acrylamide grafted and cross-linked. It is a Mg salt type cross-linked polyacrylate fiber; the third yarn It is hollow polyester filament, the specification is 167D / 144F; the fourth yarn is polyester filament, and the specification is 75D / 36F;

[0057] (1) prepare above-mentioned four kinds of yarn raw materials, meanwhile, according to the actual situation of used 30 inch double-sided knitting large circular knitting machine, prepare the bobbins necessary for above four kinds of yarns...

Embodiment 2

[0072] A method for weaving a comfortable fabric with a moisture-absorbing uniform heat-retaining structure, the steps of which are as follows:

[0073] Raw material preparation: the first yarn is a composite yarn made of 75D / 72F cross-section polyester filament and 60S polyester-cotton 80 / 20 staple yarn; the second yarn is Shuresi fiber and viscose fiber It is a compact blended yarn with a blending ratio of 40 / 60 and a specification of 32 pounds. Among them, Shuresi fiber is a kind of acrylic fiber made by a special process. It is made of acrylic acid, sodium acrylate and acrylamide. Functional moisture-absorbing and heating fibers composed of groups; the third yarn is hollow polyester fiber filament, the specification is 167D / 144F; the fourth yarn is polyester filament, the specification is 75D / 36F;

[0074] (1) prepare above-mentioned four kinds of yarn raw materials, meanwhile, according to the actual situation of used 30 inch double-sided knitting large circular knitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com