Thermal insulation building product and preparation method thereof

A thermal insulation and product technology, which is applied in the field of building materials technology and solid waste treatment, can solve the problems of large volume and no advantage in weight, and achieve the effects of high compressive strength, reduced apparent density, and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] This specific embodiment also includes the preparation method of the above-mentioned thermal insulation building products, including the following steps:

[0034]1) According to the ratio, mix the shield slag and active waste residue in the mixer and stir for 5-10 minutes until the first mixed material is obtained, then add the alkaline activator according to the ratio and continue to stir for 1-2 minutes; then add water and continue to stir for 1 -2min obtains the second mixed material of flowing state;

[0035] 2) According to the mass ratio of the total mass of foaming agent and foam stabilizer to water: 1:20-50, mix foaming agent and foam stabilizer with water to obtain foaming liquid, and foam the foaming liquid in a foaming machine Bubble to 0.25-1 times of the volume of the first mixed material to make foam;

[0036] 3) Stir the foam prepared in step 2) and the second mixed material prepared in step 1) for 2-3 minutes at a speed of 120-150 r / min to mix and mix, ...

Embodiment 1

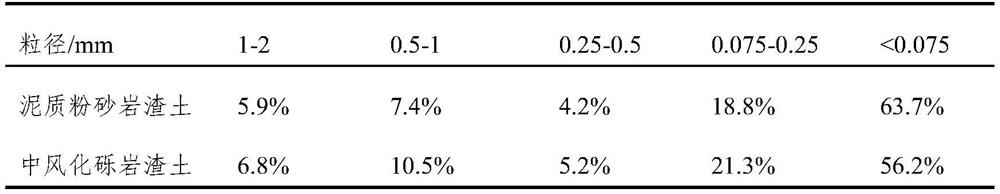

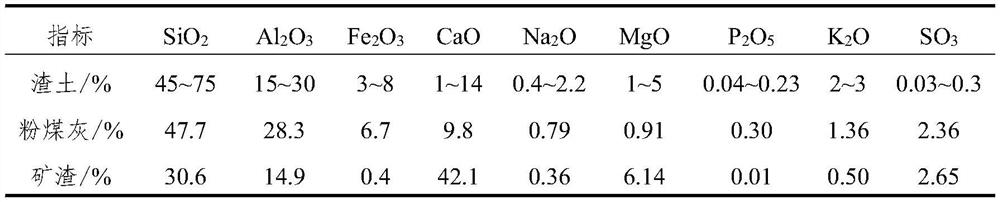

[0039] The shield slag in this example is taken from argillaceous siltstone in a certain section of the Changsha subway, and the slag material is air-dried or dried, crushed, and passed through a 2mm sieve for use; the granulated blast furnace slag has a mesh number of 200; alkaline excitation In the agent, the sodium hydroxide solution concentration is 10mol / L, and the water glass modulus is 3.26, and the mass ratio of water glass and the described sodium hydroxide solution is 2:1; Foaming agent is anionic sodium lauryl sulfate ( SDS); The foam stabilizer is a modified FM-550 type silicone resin polyether emulsion with a polyether content of 55%, all of which are commercially available.

[0040] The thermal insulation building product in this embodiment is composed of the following raw materials: argillaceous siltstone shield dregs, granulated blast furnace slag, alkaline activator, foaming liquid; wherein, the first mixed material is Calculated, it is composed of 70% shield ...

Embodiment 2

[0047] The shield slag in this example is taken from the moderately weathered conglomerate in a certain section of the Changsha subway, and the slag material is air-dried or dried, crushed, and passed through a 2mm sieve for later use; the granulated blast furnace slag has a mesh number of 200; alkaline excitation In the agent, the sodium hydroxide solution concentration is 10mol / L, and the water glass modulus is 3.26, and the mass ratio of water glass and the described sodium hydroxide solution is 2:1; Foaming agent is anionic sodium lauryl sulfate ( SDS); The foam stabilizer is a modified FM-550 type silicone resin polyether emulsion with a polyether content of 55%, all of which are commercially available.

[0048] The thermal insulation building product in this embodiment is composed of the following raw materials: moderately weathered conglomerate shield slag, granulated blast furnace slag, alkaline activator, and foaming liquid; wherein, the first mixed material is Calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com