Polyarylethersulfone containing multiple flexible side chain quaternary ammonium salt structures, and preparation method thereof

A technology of polyaryl ether sulfone and quaternary ammonium salt is applied in the field of polymer anion exchange membrane and its preparation. Water swelling, excellent dimensional stability, the effect of improving ion conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

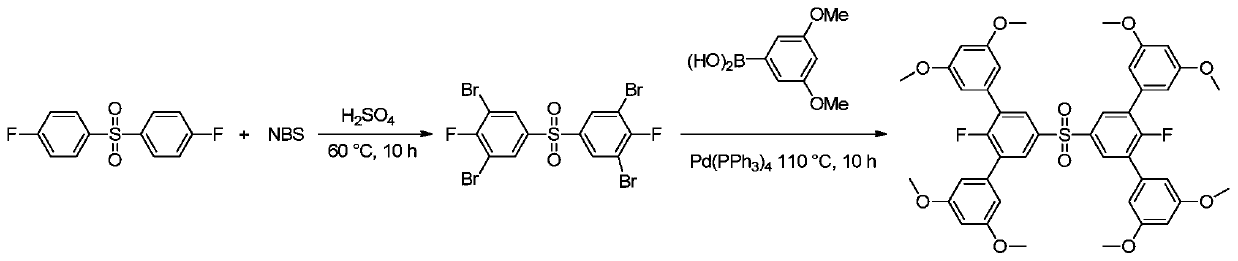

Method used

Image

Examples

Embodiment 1

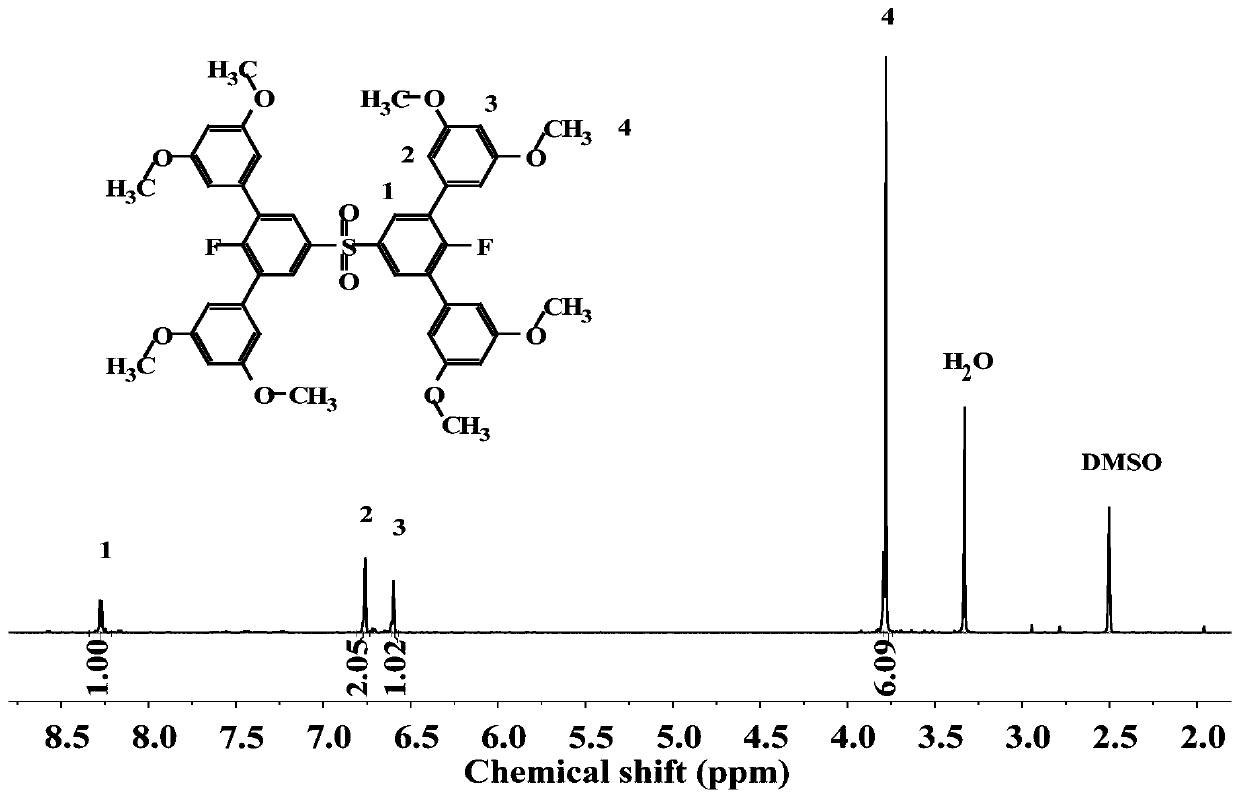

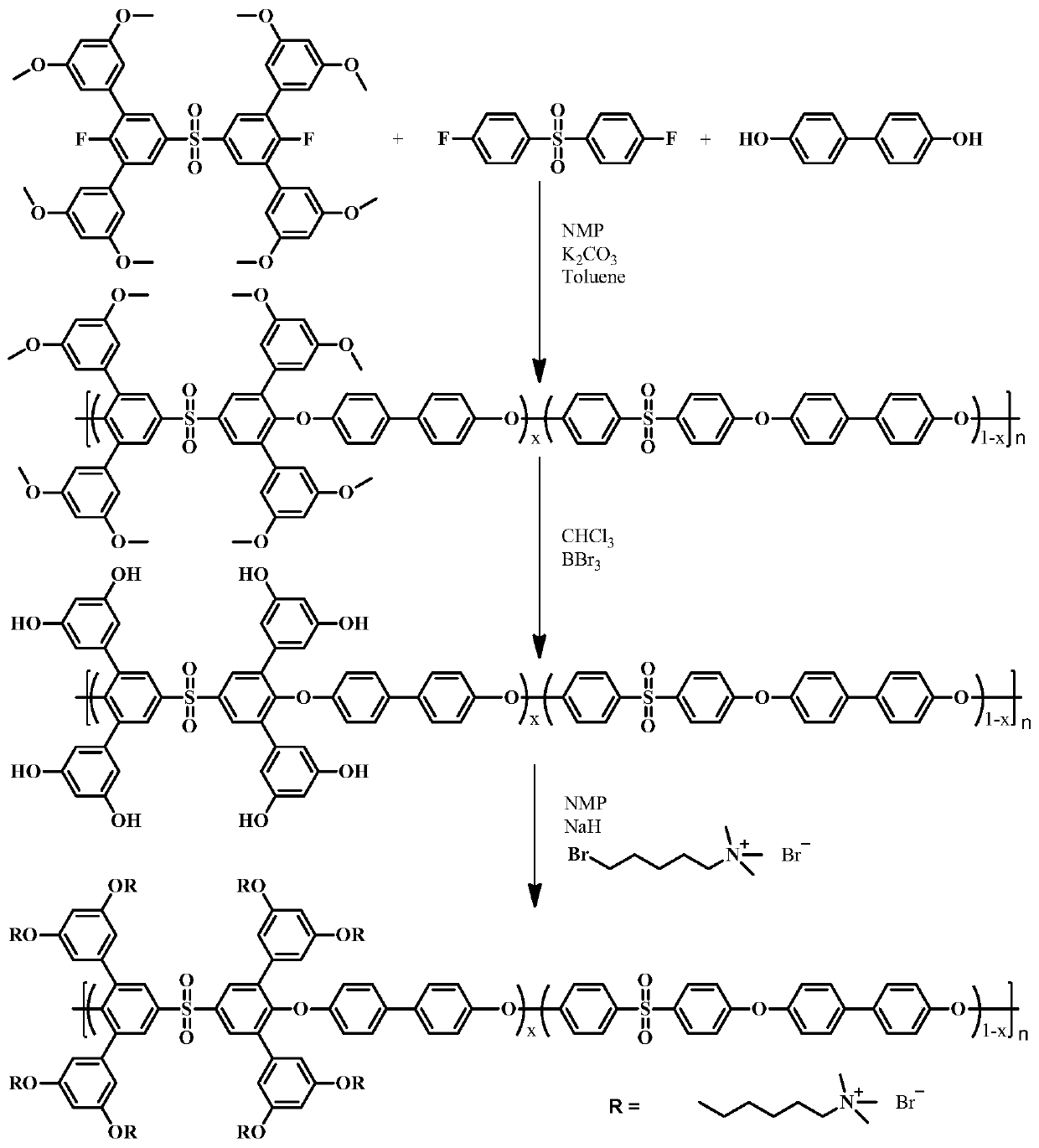

[0035] (1) Preparation of polyarylethersulfone with multiple flexible side chain quaternary ammonium salt structure

[0036] In a 100mL dry three-necked flask equipped with mechanical stirring, 1.0g (5.1mmol of hydroxyl) polyaryl ether sulfone polymer (PAES-OH-35) containing polyhydroxyl structure was dissolved in 10mL of N-methylpyrrolidone solvent, Add 0.61g (15.3mmol) of sodium hydride and 4.4g (15.3mmol) (5-bromopentyl) trimethylammonium bromide at 0°C, react at 90°C for 6h, pour the reactant into isopropyl Precipitate in alcohol to obtain polyarylethersulfone (PAES-QA-35) containing multiple flexible quaternary ammonium salt side group structures, with a yield of 98%; 1 H NMR (DMSO-d 6 ,400MHz), as attached Figure 4 as shown in c.

[0037] (2) Preparation of polyaryl ether sulfone containing polyhydroxyl structure

[0038] In a 250 mL dry three-neck flask equipped with mechanical stirring and nitrogen protection, 2.0 g (9.5 mmol methoxy) of polyarylethersulfone (PAES...

Embodiment 2

[0042] (1) Preparation of polyarylethersulfone with multiple flexible side chain quaternary ammonium salt structure

[0043] In a 100mL dry three-neck flask equipped with mechanical stirring, 1.0g (3.9mmol of hydroxyl) polyaryl ether sulfone polymer (PAES-OH-25) containing polyhydroxyl structure was dissolved in 15mL of N-methylpyrrolidone solvent, Add 0.31g (7.8mmol) of sodium hydride and 2.3g (7.8mmol) (5-bromopentyl) trimethylammonium bromide at 0°C, react at 90°C for 8h, pour the reactant into isopropyl Settled in alcohol to obtain polyarylethersulfone (PAES-QA-25) with multiple flexible quaternary ammonium salt side group structures, with a yield of 98%.

[0044] (2) Preparation of polyaryl ether sulfone containing polyhydroxyl structure

[0045] In a 250 mL dry three-neck flask equipped with mechanical stirring and nitrogen protection, 2.0 g (7.5 mmol methoxy) of polyarylether sulfone (PAES-M-25) containing polymethoxyl structure was dissolved in 100 mL of chloroform I...

Embodiment 3

[0049] (1) Preparation of polyarylethersulfone with multiple flexible side chain quaternary ammonium salt structure

[0050] In a 100mL dry three-necked flask equipped with mechanical stirring, 1.0g (2.6mmol of hydroxyl) polyaryl ether sulfone polymer (PAES-OH-15) containing polyhydroxyl structure was dissolved in 15mL of N-methylpyrrolidone solvent, Add 0.31g (7.7mmol) of sodium hydride and 2.2g (7.7mmol) (5-bromopentyl) trimethylammonium bromide at 0°C, react at 90°C for 8h, pour the reactant into isopropyl Settled in alcohol to obtain polyarylethersulfone (PAES-QA-15) with a structure containing multiple flexible quaternary ammonium salt side groups, with a yield of 98%.

[0051] (2) Preparation of polyaryl ether sulfone containing polyhydroxyl structure

[0052] In a 250 mL dry three-neck flask equipped with mechanical stirring and nitrogen protection, 2.0 g (5.0 mmol methoxy) of polyarylethersulfone (PAES-M-15) containing polymethoxyl structures was dissolved in 100 mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com