A chain extender masterbatch for PET extrusion foaming and its preparation method and application

A technology for extruding foaming and chain extenders, applied in the field of chain extenders, can solve the problems of increasing the complexity of the processing process, reducing the final product, affecting the stability, etc., to reduce the construction cost and the complexity of the extrusion process, The effect of reducing the degree of thermal degradation and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

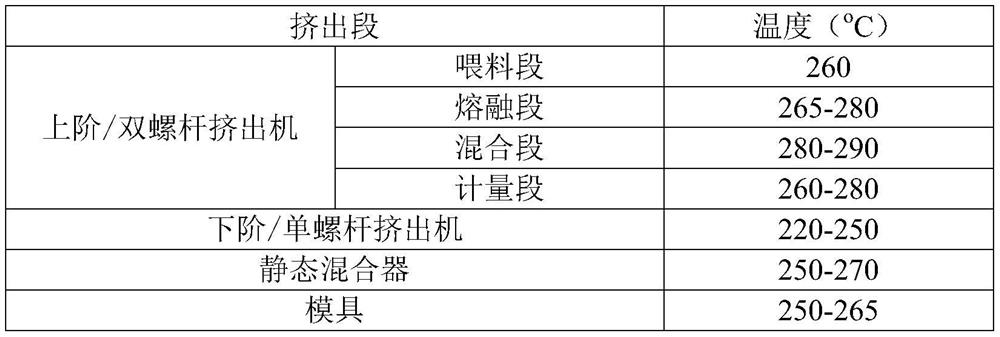

[0045] A kind of chain extender masterbatch that is used for PET extrusion foaming, adopts following method to prepare:

[0046] (1) Ingredients: According to parts by weight, weigh 5 parts of PMDA, 25 parts of PBT, and 70 parts of POE-g-GMA. The melting temperature of PBT is 190°C and the intrinsic viscosity is 1.0dL / g. The index is 2g / 10min, and the grafting rate of GMA in POE-g-GMA is 1%;

[0047] (2) Use a twin-screw extruder to melt and blend the above-mentioned components, and the blending temperature is selected to be 205°C; all components are fed simultaneously from the main feeding port of the extruder, and are melted and plasticized, blended and then blended. Extruded through a porous head, the screw diameter D of the extruder=30mm, the length-to-diameter ratio L / D of the extruder screw is 30-48, which is selected as 40 in this embodiment, and the screw speed is 100-500rpm. In the embodiment, 200 rpm is selected, and the extruded material is air-cooled and pelletize...

Embodiment 2

[0049] A kind of chain extender masterbatch that is used for PET extrusion foaming, adopts following method to prepare:

[0050] (1) Ingredients: Weigh 5 parts of PMDA, 25 parts of PBT, 35 parts of POE, and 35 parts of POE-g-GMA according to parts by weight. The melting temperature of PBT is 190°C and the intrinsic viscosity is 1.0dL / g. The melting temperature of POE The index is 1g / 10min, the melt index of POE-g-GMA is 2g / 10min, and the grafting rate of GMA in POE-g-GMA is 1%;

[0051] (2) A twin-screw extruder is used to melt and blend the above-mentioned components, and all components are fed simultaneously at the main feeding port of the extruder. The screw diameter of the extruder is D=30mm, and the aspect ratio L / D =48, the blending temperature is 205° C., the screw speed is 200 rpm, and the extruded material is air-cooled and pelletized.

Embodiment 3

[0053] A kind of chain extender masterbatch that is used for PET extrusion foaming, adopts following method to prepare:

[0054] (1) Ingredients: Weigh 10 parts of PMDA, 40 parts of PBT, 30 parts of POE, and 20 parts of POE-g-GMA according to parts by weight. The melting temperature of PBT is 190°C and the intrinsic viscosity is 1.0dL / g. The index is 1g / 10min, the melt index of POE-g-GMA is 2g / 10min, and the grafting rate of GMA in POE-g-GMA is 1%;

[0055] (2) A twin-screw extruder is used to melt and blend the above-mentioned components, and all components are fed simultaneously at the main feeding port of the extruder. The screw diameter of the extruder is D=30mm, and the aspect ratio L / D =48, the blending temperature is 205° C., the screw speed is 200 rpm, and the extruded material is air-cooled and pelletized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com