Flame-retardant functional protein master batch and preparation method thereof

A technology of functional masterbatch and protein, applied in the field of polymer material composition, can solve the problems of poor dispersibility and poor compatibility of protein materials, and achieve the effects of improving the uniformity of carbon formation, solving the difficulty of dispersibility, and improving the density and stability characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

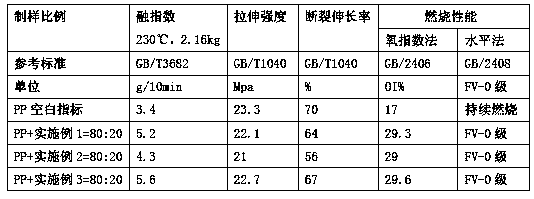

Embodiment 1

[0042] The components by mass include: 60Kg of soybean extract concentrated protein dry powder, 6Kg of lignocellulose, 8 Kg of sodium silicate, 2 Kg of coupling agent vinyl trichlorosilane, 3 Kg of branching agent, 18 Kg of PBAT, zinc stearate 1 Kg, EVA wax 1.5 Kg, antioxidant 0.5 Kg.

[0043] Put the soybean protein component, lignocellulose component, sodium silicate component and branching agent component in the formula together into the autoclave, adjust the pressure to 3MPa, the mixing speed to 150r / min, and the temperature to 120°C. The pre-dispersion time is 35 minutes later. Put in the coupling agent vinyltrichlorosilane, adjust the pressure to 5MPa, and the temperature at 145°C, and continue mixing and dispersing for 15 minutes.

[0044]Put the zinc stearate, EVA wax, antioxidant and PBAT of the remaining components into the high-speed mixer and mix all the components evenly; the speed of the high-speed mixer is 120r / min, and the temperature is adjusted from 145 ° C ...

Embodiment 2

[0047] Formula components, including: 30 Kg of concentrated protein dry powder extracted from soybean, 30 Kg of concentrated protein dry powder extracted from corn, 6 Kg of lignocellulose, 8 Kg of sodium silicate, 2 Kg of coupling agent, 3 Kg of branching agent, 18 Kg of PBAT, hard Zinc fatty acid 1 Kg, EVA wax 1.5Kg, antioxidant 0.5 Kg.

[0048] Put the protein component, lignocellulose component, sodium silicate component and branching agent component in the formula together into the autoclave, adjust the pressure to 3MPa, adjust the mixing speed to 150r / min, adjust the temperature to 120°C, and pre- After the dispersion time was 35 minutes, the coupling agent vinyltrichlorosilane was added, the pressure was adjusted to 5 MPa, the temperature was 145° C., and the mixing was continued for 15 minutes.

[0049] Put the zinc stearate, EVA wax, antioxidant and PBAT of the remaining components into the high-speed mixer and mix all the components evenly; ℃, the pressure is adjuste...

Embodiment 3

[0052] According to the quality components, it includes: 30 Kg of concentrated protein dry powder extracted from soybean, 30 Kg of concentrated protein dry powder extracted from seaweed, 6 Kg of lignocellulose, 8 Kg of sodium silicate, 2 Kg of coupling agent, 3 Kg of branching agent, 18 Kg of PBAT, Zinc stearate 1 Kg, EVA wax 1.5 Kg, antioxidant 0.5 Kg.

[0053] Put the protein component, lignocellulose component, sodium silicate component and branching agent component in the formula together into the autoclave, adjust the pressure to 3MPa, adjust the mixing speed to 150r / min, adjust the temperature to 120°C, and pre- Dispersion time was 35 minutes, then the coupling agent vinyltrichlorosilane was added, the pressure was adjusted to 5 MPa, the temperature was 145°C, and the mixing was continued for 15 minutes.

[0054] Put the zinc stearate, EVA wax, antioxidant and PBAT of the remaining components into the high-speed mixer and mix all the components evenly; ℃, the pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com