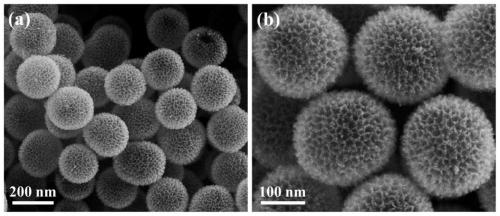

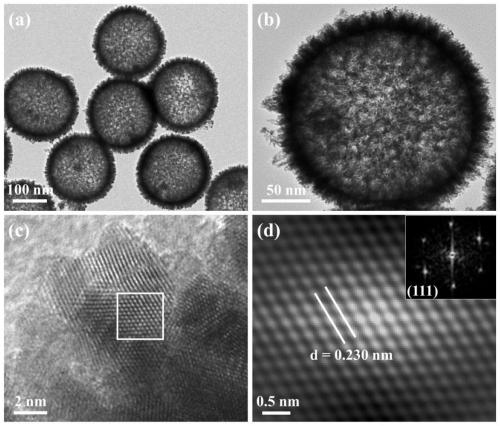

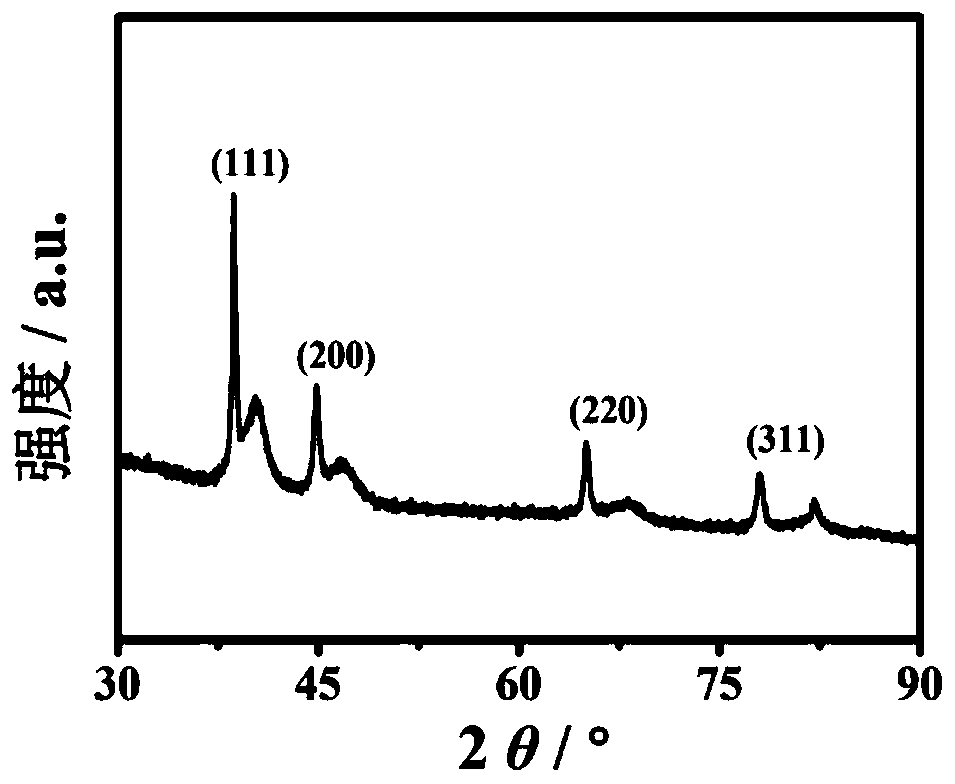

Mesoporous nanosphere with palladium-platinum yolk-eggshell structure for catalyzing methanol oxidation reaction and preparation method of mesoporous nanosphere

A methanol oxidation and palladium nanotechnology, applied in structural parts, electrochemical generators, fuel cells, etc., can solve the problems of unfavorable industrial production, high platinum consumption, poor catalytic performance, etc., and achieve excellent catalytic performance and stability, particle size The effect of uniform diameter and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a palladium@platinum egg yolk-eggshell structure mesoporous nanosphere methanol oxidation electrocatalyst, the method comprising the following steps:

[0045] 1) Potassium chloroplatinite, sodium chloropalladate and chloroauric acid solutions with a concentration of 20mM, ascorbic acid solution with a concentration of 0.1M, and cetyltrimethylammonium bromide solution with a mass fraction of 0.1%;

[0046] 2) Dissolve 20mg of F127 in 2mL of sodium chloropalladate solution, add 2mL of ascorbic acid solution, react in an oil bath at 95°C for 3 hours, add 2mL of hexadecyltrimethylammonium bromide solution, and continue the reaction for 1 hour, centrifuged to collect the product to obtain palladium nanoparticles, and the collected palladium nanoparticles were dispersed in 40mL of water for later use;

[0047] 3) Take 4 mL of palladium nanoparticle solution, disperse it in 20 mL of isopropanol and 65 μL of tetraethyl orthosilicate mixed solution, add 0....

Embodiment 2

[0053] A method for preparing a mesoporous platinum nanocage methanol oxidation electrocatalyst, the method comprising the steps of:

[0054] 1) Potassium chloroplatinite and chloroauric acid solutions with a concentration of 20mM, ascorbic acid solution with a concentration of 0.1M, and cetyltrimethylammonium bromide solution with a mass fraction of 0.1%;

[0055] 2) Mix 20 mL of isopropanol and 65 μL of tetraethyl orthosilicate evenly, add 0.5 mL of ammonia water, and stir vigorously at room temperature for 12 hours. After the reaction is completed, centrifuge and wash to obtain a silica precursor, and put the product at 50 ° C drying in an oven;

[0056] 3) Dissolve 0.05g of silica nanoparticles and 0.2mL of 3-aminopropyltrimethoxysilane in 10mL of isopropanol, heat the reaction at 80°C for 12 hours, and collect the product by centrifuging and washing at 50°C Dry under vacuum for 24 hours;

[0057] 4) Weigh 2 mg of 3-aminopropyltrimethoxysilane-modified silica nanoparticl...

Embodiment 3

[0061] A method for preparing a palladium@platinum egg yolk-eggshell structure mesoporous nanosphere methanol oxidation electrocatalyst, the method comprising the following steps:

[0062] 1) Potassium chloroplatinite, sodium chloropalladate and chloroauric acid solutions with a concentration of 5mM, ascorbic acid solution with a concentration of 0.02M, and cetyltrimethylammonium bromide solution with a mass fraction of 0.02%;

[0063] 2) Dissolve 5mg of F127 in 1mL of sodium chloropalladate solution, add 1mL of ascorbic acid solution, react in an oil bath at 50°C for 1 hour, add 1mL of hexadecyltrimethylammonium bromide solution, and continue the reaction for 0.5 hours , the product was collected by centrifugation to obtain palladium nanoparticles, and the collected palladium nanoparticles were redispersed in 10 mL of water for later use;

[0064] 3) Take 1 mL of palladium nanoparticle solution, disperse it in 10 mL of isopropanol and 10 μL of tetraethyl orthosilicate mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com