Magnesium alloy bone nail and preparation method and application thereof

A magnesium alloy and bone nail technology, applied in the field of medical devices, can solve problems such as customized drug types and dosages, non-functional effects, and unclear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

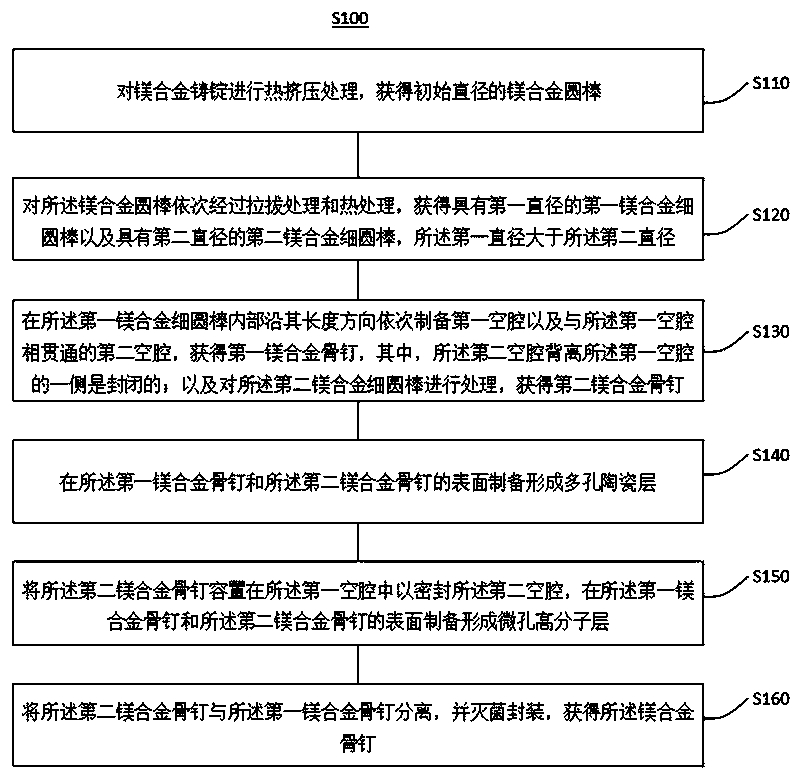

[0041] Such as figure 1 As shown, the first aspect of the present invention provides a method for preparing a magnesium alloy bone nail S100, comprising:

[0042] S110, performing hot extrusion treatment on the magnesium alloy ingot to obtain a magnesium alloy round rod with an initial diameter.

[0043]S120, sequentially drawing and heat-treating the magnesium alloy round rod to obtain a first magnesium alloy thin round rod with a first diameter and a second magnesium alloy thin round rod with a second diameter, the first diameter being greater than the second diameter.

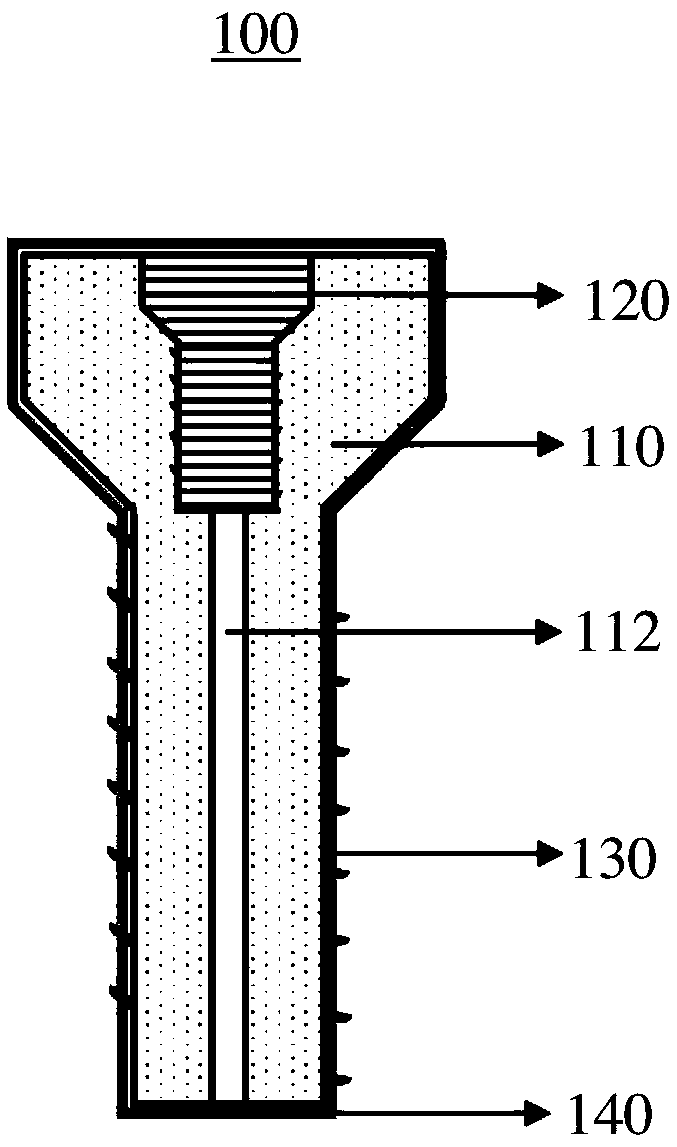

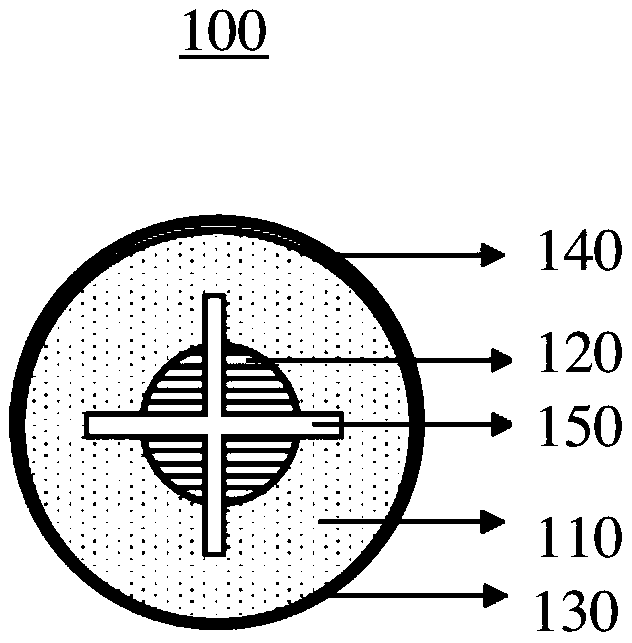

[0044] S130, sequentially prepare a first cavity and a second cavity communicating with the first cavity inside the first magnesium alloy thin round rod along its length direction to obtain a first magnesium alloy bone nail, wherein the The side of the second cavity away from the first cavity is closed; and the second magnesium alloy thin round rod is processed to obtain the second magnesium alloy bone nail...

Embodiment 1

[0072] The preparation method of the magnesium alloy bone nail in this example, the specific steps are as follows:

[0073]S1. Select a magnesium alloy ingot whose composition is 2wt%Zn, 1wt%Ca, and the balance is Mg, heat it to 360°C in a resistance furnace, and perform hot extrusion at a temperature of 200°C, with an extrusion ratio of 15, to obtain the initial Magnesium alloy round rod with a diameter of 12mm.

[0074] S2. Drawing the magnesium alloy round rod obtained in step 1 at room temperature, and heat-treating it at 200° C. for 1 hour to obtain a first magnesium alloy thin round rod with a first diameter of 10 mm and a second magnesium alloy with a second diameter of 4 mm. Thin round stick.

[0075] S3. Machining and tapping the first magnesium alloy thin round rod and the second magnesium alloy thin round rod obtained in step 2 to obtain the first magnesium alloy bone nail with a cavity and the second magnesium alloy bone nail with a closed cavity ; Wherein, a fir...

Embodiment 2

[0081] The preparation method of the magnesium alloy bone nail in this example, the specific steps are as follows:

[0082] S1. Select a magnesium alloy ingot with a composition of 1.5wt% Zn and the balance of Mg, heat it in a resistance furnace to 400°C, and perform hot extrusion at a temperature of 150°C. The extrusion ratio is 30, and the initial diameter is 12mm. Magnesium alloy round rod;

[0083] S2. The magnesium alloy round rod obtained in step 1 is drawn at room temperature, and heat-treated at 300° C. for 1 hour, the first magnesium alloy thin round rod with a first diameter of 4 mm and the second magnesium alloy rod with a second diameter of 1.5 mm Alloy thin round rod.

[0084] S3. Machining and tapping the first magnesium alloy thin round rod and the second magnesium alloy thin round rod obtained in step 2 to obtain a first magnesium alloy bone nail with a cavity and a second magnesium alloy bone nail with a closed cavity Nail; wherein, a first cavity and a seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com