A kind of preparation method of extrusion roller

A squeezing roller and pressure technology, which is applied in the field of composite material preparation, can solve the problems of high production cost of cemented carbide stud extrusion rollers, low bonding strength between the stud and the base of the roller sleeve, and high price of cemented carbide materials. Achieve the effect of easy mass production, less defects and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

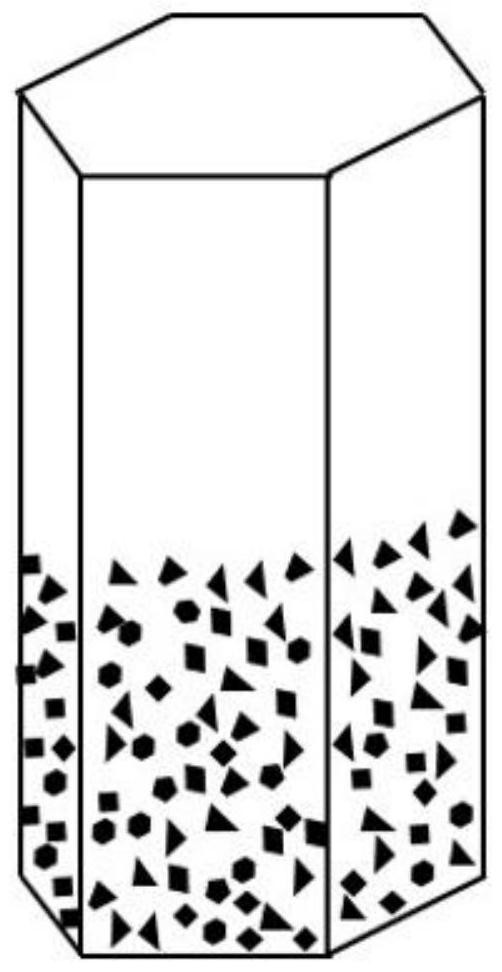

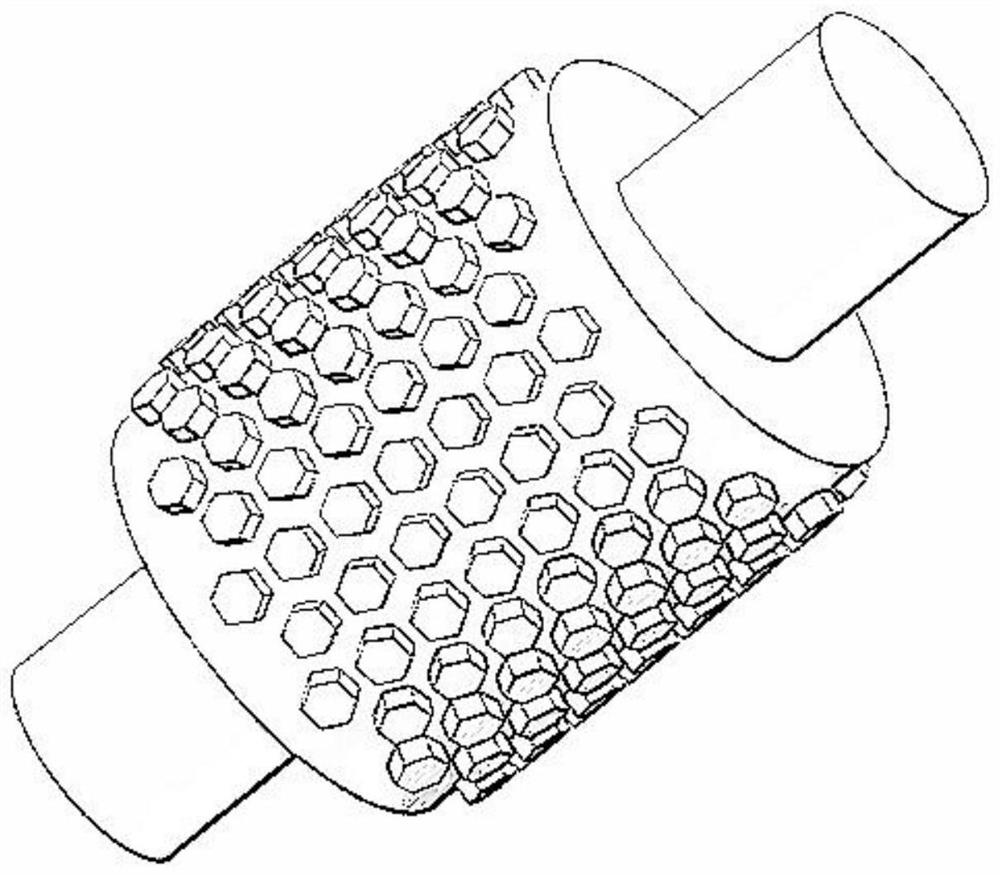

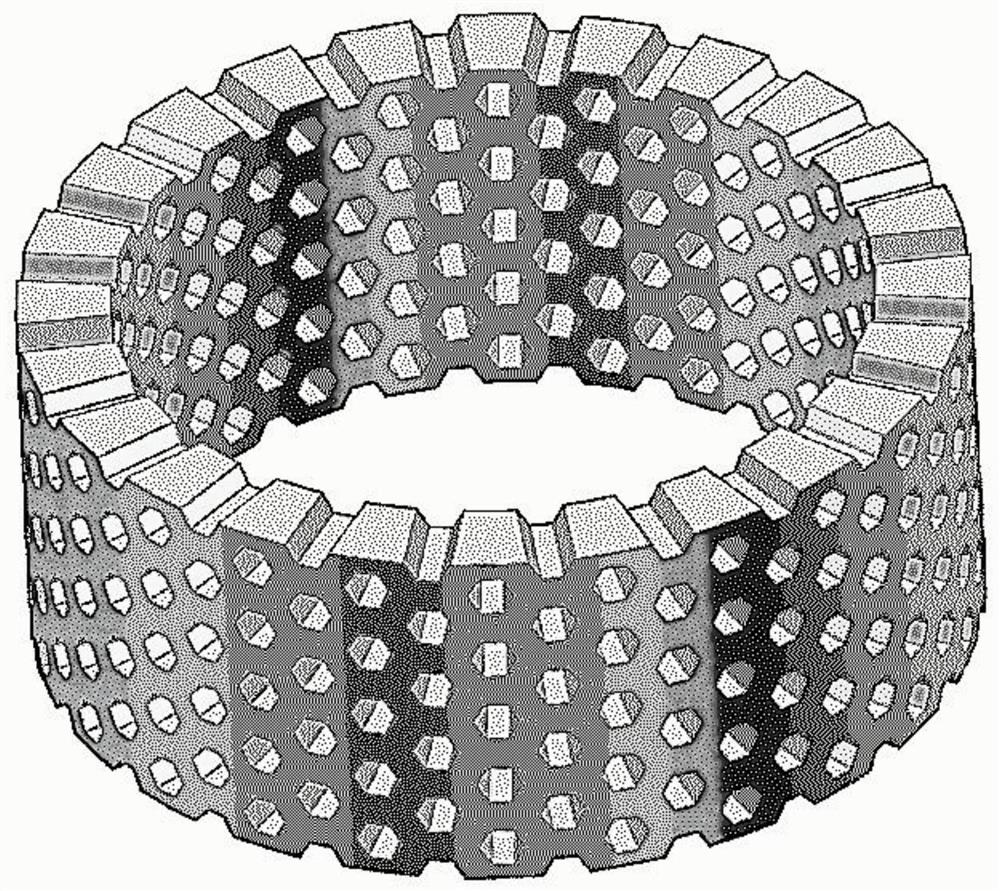

[0042] The invention provides a method for preparing a stud extrusion roller of composite material. The process can rapidly prepare a high-stress extrusion roller of stud composite material with high wear resistance, long service life, low cost and convenient industrial mass production.

[0043]In order to achieve the above object, the technical solution of the present invention is as follows. A preparation method of a composite stud extrusion roller, the specific steps of the method are as follows:

[0044] (1) Add ceramic particles and metal powder into high-energy ball milling equipment in a ratio of 3:1-5 by volume, fully mix them with liquid ball milling medium, and obtain the ball milling time according to the formula for calculating the ball milling time of ceramic particles and metal powder;

[0045]

[0046] Among them, the reference time of ball milling is 6 hours, and the conversion value of volume ball milling coefficient is K V 1, V m is the volume content of...

Embodiment 1

[0056] The preparation method of the composite stud extrusion roller, the specific steps are as follows:

[0057] (1) Add 100-mesh ZTA ceramic particles and 500-mesh carbon ferrochrome powder into the ball milling equipment according to the volume ratio of 3:2, and obtain the ball milling time according to the calculation formula of ceramic particles and metal powder ball milling time, and use absolute ethanol 17.3 hours of wet grinding for ball milling media;

[0058] (2) Add 5% aluminum sol in the mixed powder according to the mass ratio, stir evenly and add it into a silica gel mold, heat it to 150° C. for curing, keep it warm for 5 minutes, and obtain a molded ZTA ceramic preform after demoulding;

[0059] (3) Fix the formed ZTA ceramic preform into a die-casting mold and preheat the mold to 400°C, preheat the ceramic preform to 650°C, and cast high-chromium cast iron metal liquid. The die-casting pressure of the die-casting machine is 50MPa, and the die-casting The speed...

Embodiment 2

[0062] The preparation method of the composite stud extrusion roller, the specific steps are as follows:

[0063] (1) Add 110-mesh ZTA ceramic particles and 270-mesh high-chromium cast iron powder into the ball milling equipment at a ratio of 3:1 by volume, and obtain the ball milling time according to the calculation formula of ceramic particles and metal powder ball milling time, using absolute ethanol as Wet milling with ball milling media for 14.9 hours;

[0064] (2) Add 6% aluminum sol in the mixed powder according to the mass ratio, stir evenly and add it into a silica gel mold, heat it to 160° C. for curing, keep it warm for 3 minutes, and obtain a molded ZTA ceramic preform after demoulding;

[0065] (3) Fix the molded ZTA ceramic prefabricated body in the die-casting mold and preheat it. The preheating temperature is 850°C. Cast nickel-hard cast iron metal liquid. The die-casting pressure of the die-casting machine is 75MPa, and the die-casting speed is 18mm / s. Hold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com