High-temperature-resistant geocell material and preparation method thereof

A geocell and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant geocell materials and its preparation, can solve the problems of poor fusion of polyolefin geocell materials, low notched impact strength of cantilever beams, and poor physical and mechanical properties. , to achieve the effect of good comprehensive performance, excellent high temperature resistance and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

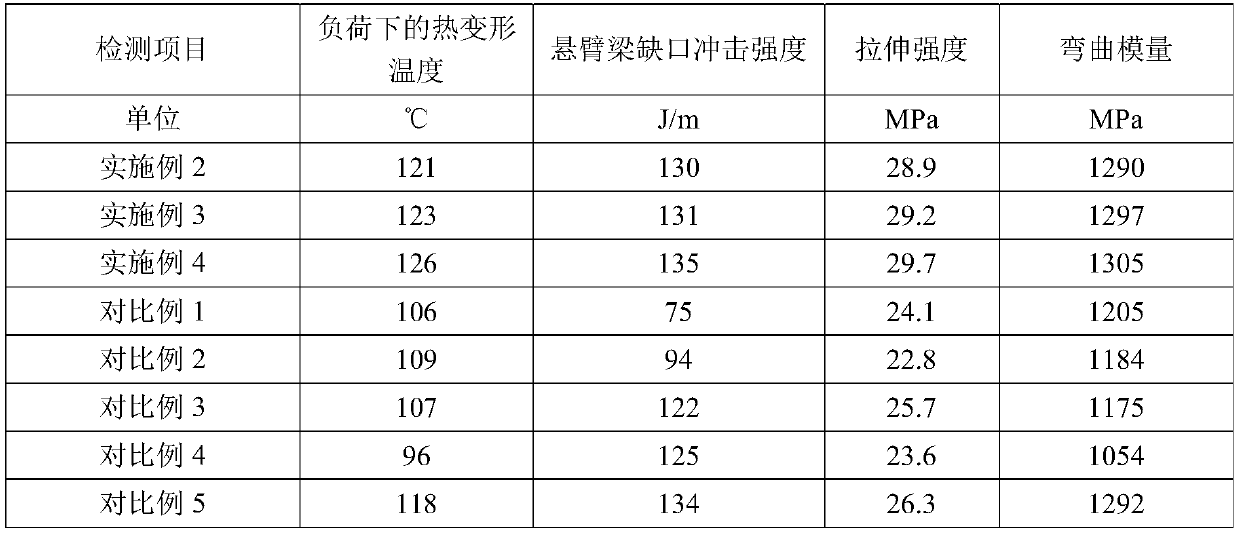

Examples

Embodiment 1

[0083] A high-temperature-resistant geocell material is made of the following raw materials in parts by weight:

[0084] High-density polyethylene: 55-70 parts,

[0085] Ethylene-vinyl acetate copolymer: 6-13 parts,

[0086] Polyamide 6: 7-15 parts,

[0087] Nano-graphene oxide grafted with silane coupling agent: 2-5 parts,

[0088] Nano reinforcement filler: 6-10 parts,

[0089] Interface compatibilizer: 4-8 parts,

[0090] UV absorber: 0.2-1 parts,

[0091] Antioxidant: 0.3-1 part,

[0092] Processing aid: 0.4-1 part;

[0093] The nano-reinforcing filler is nano basic magnesium sulfate whisker;

[0094] The interface compatibilizer is at least two of maleic anhydride grafted polyethylene, silane coupling agent KH560 and aluminate coupling agent DL-411.

[0095] Preferably, the high temperature-resistant geocell material is made of raw materials including the following parts by weight:

[0096] High-density polyethylene: 60-65 parts,

[0097] Ethylene-vinyl acetate ...

Embodiment 2

[0133] A high-temperature-resistant geocell material is made of the following raw materials in parts by weight:

[0134] HDPE: 60 parts,

[0135] Ethylene-vinyl acetate copolymer: 8 parts,

[0136] Polyamide 6: 10 parts,

[0137] Nano-graphene oxide grafted with silane coupling agent: 3 parts,

[0138] Nano reinforcement filler: 7 parts,

[0139] Interface compatibilizer: 5 parts,

[0140] UV absorber: 0.3 parts,

[0141] Antioxidant: 0.5 part,

[0142] Processing aid: 0.5 parts;

[0143] The nano-reinforcing filler is nano basic magnesium sulfate whisker;

[0144] The interface compatibilizer is at least two of maleic anhydride grafted polyethylene, silane coupling agent KH560 and aluminate coupling agent DL-411.

[0145] In this example, the high-density polyethylene is Fushun Petrochemical FHF7750M.

[0146] In this example, the ethylene-vinyl acetate copolymer is Celanese 1210.

[0147] In this example, the polyamide 6 is Baling Petrochemical BL2280.

[0148] In...

Embodiment 3

[0159] A high-temperature-resistant geocell material is made of the following raw materials in parts by weight:

[0160] HDPE: 65 parts,

[0161] Ethylene-vinyl acetate copolymer: 11 parts,

[0162] Polyamide 6: 14 parts,

[0163] Nano-graphene oxide grafted with silane coupling agent: 4 parts,

[0164] Nano reinforcement filler: 9 parts,

[0165] Interface compatibilizer: 7 parts,

[0166] UV absorber: 0.7 parts,

[0167] Antioxidant: 0.9 parts,

[0168] Processing aid: 1 part;

[0169] The nano-reinforcing filler is nano basic magnesium sulfate whisker;

[0170] The interface compatibilizer is at least two of maleic anhydride grafted polyethylene, silane coupling agent KH560 and aluminate coupling agent DL-411.

[0171] In this example, the high-density polyethylene is Fushun Petrochemical FHF7750M.

[0172] In this example, the ethylene-vinyl acetate copolymer is Celanese 1210.

[0173] In this example, the polyamide 6 is Baling Petrochemical BL2280.

[0174] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com