Polymeric aluminum-iron-magnesium composite flocculant for treating dye wastewater, and preparation method of polymeric aluminum-iron-magnesium composite flocculant

A composite flocculant and polymerized aluminum-iron technology, which is applied in water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc., can solve the problems of low cost and difficult to achieve high decolorization rate of dye wastewater treated by flocculants. Achieve high removal rate, less dosage and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

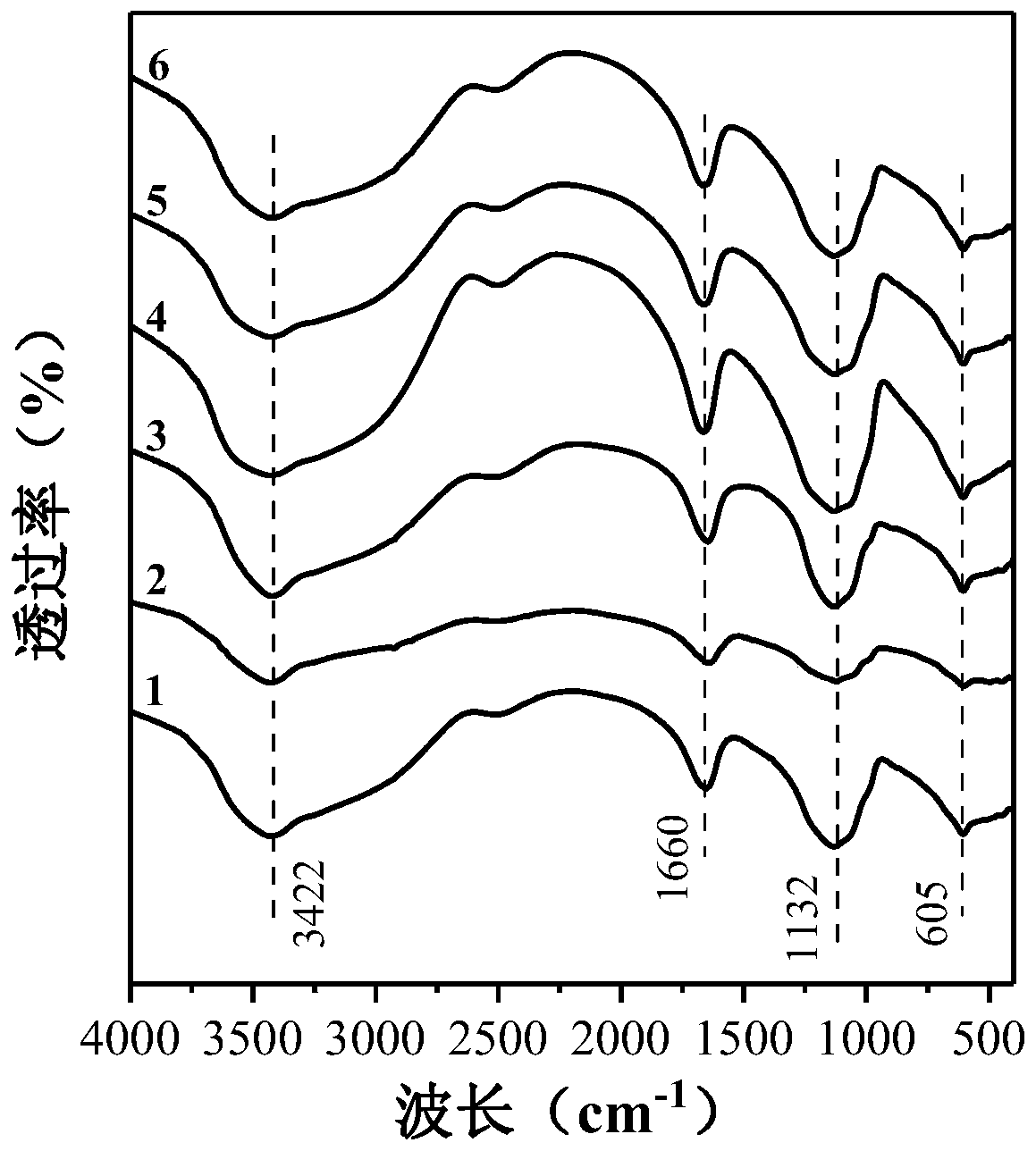

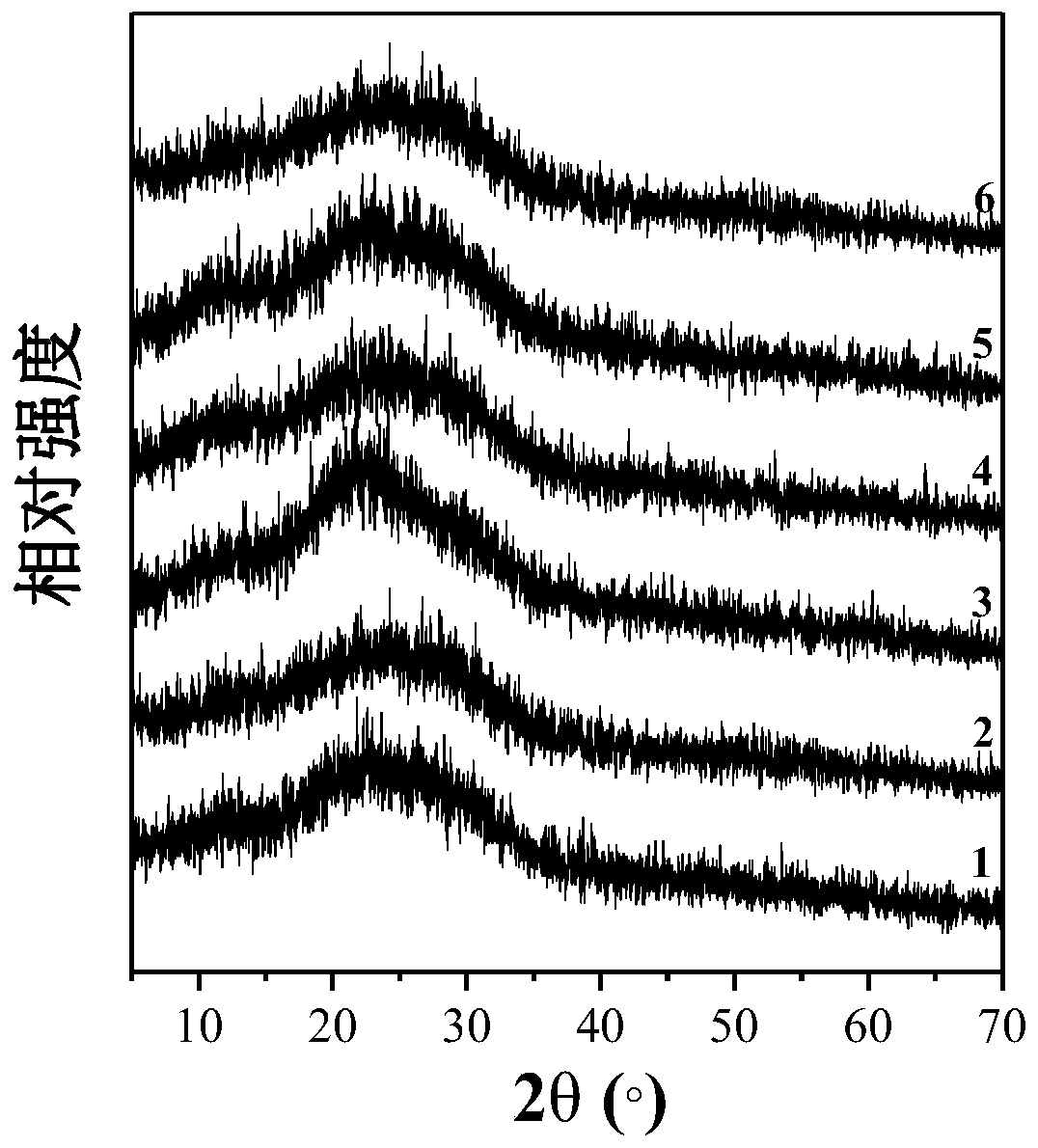

[0029] Dissolve 20g of aluminum sulfate octadecahydrate in 25mL of distilled water, stir until the solution is clear and transparent, add 2g of ferric sulfate, and continue stirring until the solution is clear and transparent; put the above solution into a reactor with a stirring and reflux device, and heat slowly to 70°C and keep the temperature basically constant, then dropwise add 0.8mL of 85wt% phosphoric acid solution, and stir for 10min at a speed of 90r / min; keep the temperature of the previous step basically constant, add 1.2g of magnesium oxide to the reactor, adjust The stirring speed of the reactor is 160r / min. After the solid dissolves completely, slowly add sodium carbonate solid until the pH=3 of the solution; keep the temperature in the previous step unchanged, and adjust the stirring speed of the reactor to be 120r / min. Insulate for 4 hours, take out the liquid in the reactor, let it stand and cool to room temperature, and obtain the polymerized aluminum-iron-ma...

Embodiment 2

[0033]Dissolve 20g of aluminum sulfate octadecahydrate in 25mL of distilled water, stir until the solution is clear and transparent, add 2g of ferric sulfate, and continue stirring until the solution is clear and transparent; put the above solution into a reactor with a stirring and reflux device, and heat slowly to 90°C and keep the temperature basically constant, then dropwise add 0.8mL of 85wt% phosphoric acid solution, and stir for 10min at a speed of 120r / min; keep the temperature of the previous step basically constant, add 0.8g of magnesium oxide to the reactor, adjust The stirring speed of the reactor is 200r / min. After the solid is completely dissolved, slowly add sodium carbonate solid until the pH of the solution=3; keep the temperature in the previous step unchanged, adjust the stirring speed of the reactor to 150r / min, and keep the reactor warm After 2 hours, the liquid in the reactor was taken out, allowed to stand and cooled to room temperature, and the polymeriz...

Embodiment 3

[0037] Dissolve 20g of aluminum sulfate octadecahydrate in 25mL of distilled water, stir until the solution is clear and transparent, add 2g of ferric sulfate, and continue stirring until the solution is clear and transparent; put the above solution into a reactor with a stirring and reflux device, and heat slowly to 80°C and keep the temperature basically constant, then dropwise add 0.8mL of 85wt% phosphoric acid solution, and stir for 10min at a speed of 100r / min; keep the temperature of the previous step basically constant, add 0.8g of magnesium oxide to the reactor, adjust The stirring speed of the reactor is 180r / min. After the solid is completely dissolved, slowly add sodium carbonate solid until the pH of the solution=2.5; keep the temperature in the previous step unchanged, adjust the stirring speed of the reactor to 135r / min, and keep the reactor warm 3h, take out the liquid in the reactor, let it stand and cool down to room temperature, and obtain the polymerized alum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap