Special flavor functional duck meat-orgotein composite emulsified sausage and preparation method thereof

A compound emulsification and liver protein technology, applied in the food field, can solve the problems of increasing the risk of epidemic diseases and chronic diseases, adverse effects on human health, and reducing product quality, and achieves the protection of color and luster, shortening of pickling time, and increased emulsification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A duck meat and liver protein compound emulsified sausage with edible fungus flavor and functional ingredients, the dried edible fungi are crushed into powder, the duck liver protein is phosphorylated, and the raw meat is prepared, and the ingredients are marinated, rolled and chopped Mixing, sausage enema, steaming, smoking, and cooling to obtain a functional duck and liver compound emulsified sausage product with anti-oxidation, rich in dietary fiber, and rich in nutrition. The preparation method specifically includes the following steps:

[0040] (1) Preparation of edible fungus powder: select clean and tidy matsutake dry products, grind them into fine powder with a superfine grinding machine, and then pass through a 100-mesh sieve to make matsutake powder;

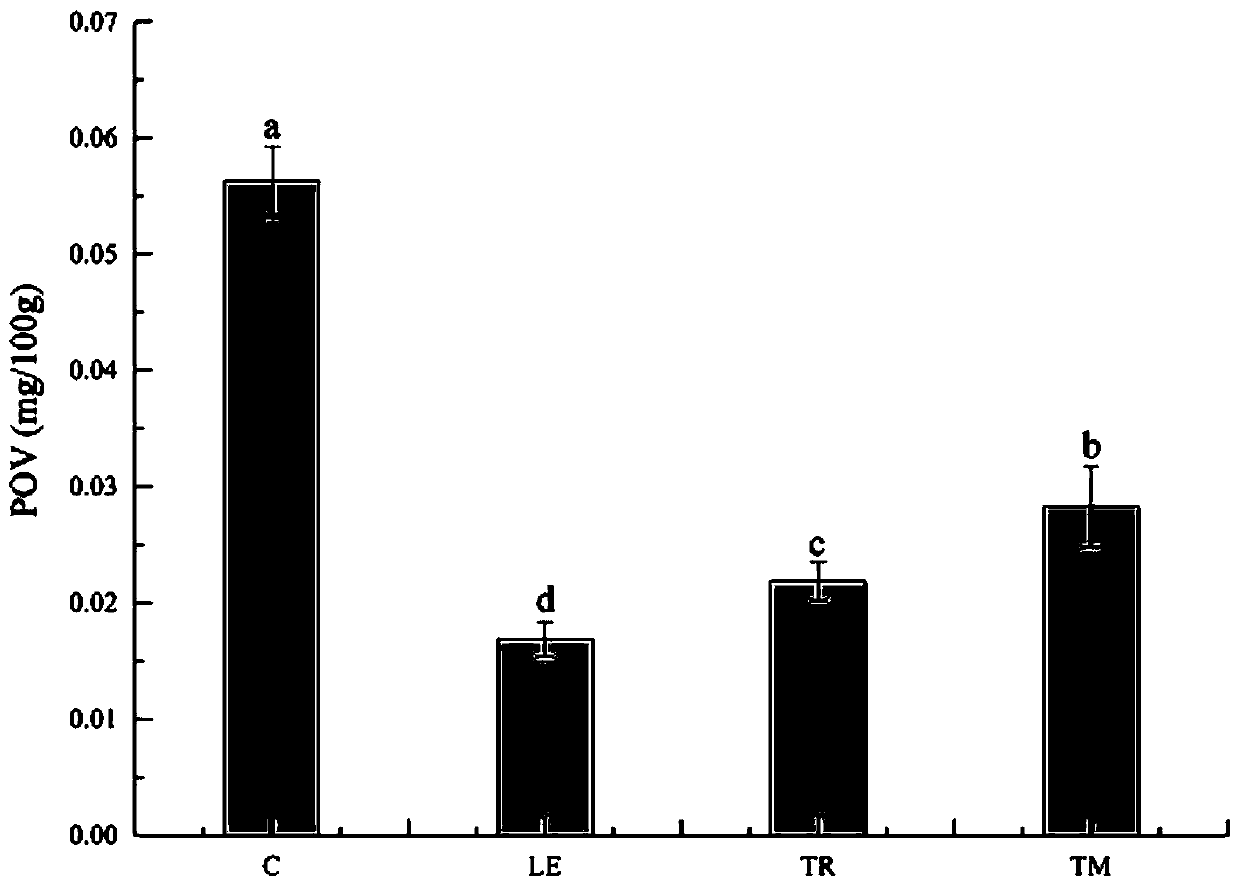

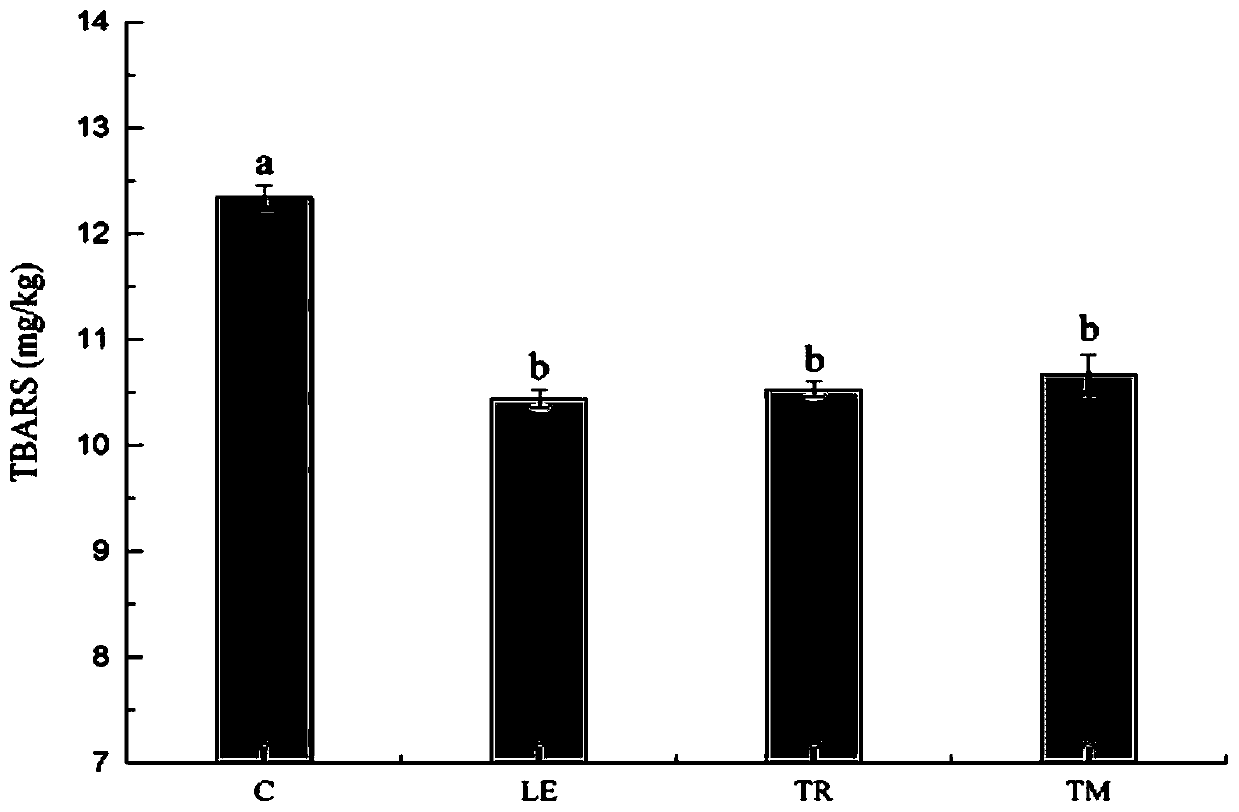

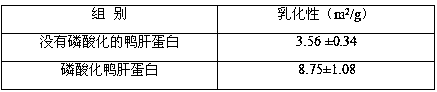

[0041] (2) Preparation of phosphorylated duck liver crude protein: remove the fascia and fat blocks on the surface of the duck liver, clean it, mix the duck liver with water at a mass ratio of 1:6, and place it i...

Embodiment 2

[0049]The same as the above example 1, the difference is: step (2) in the preparation of phosphorylated duck liver crude protein: remove the fascia and fat blocks on the surface of duck liver, clean it, and mix duck liver and water with a mass ratio of 1:4. After mixing in proportion, place it in a high-speed homogenizer, homogenize at 2000rpm for 10min, adjust the pH value to 9.6-9.8, stir for 5min, centrifuge at 3000rpm for 10min, take the supernatant and adjust the pH value to 4.70-4.90, stir After 5 minutes, centrifuge at 6000 rpm for 10 minutes, take the precipitate and add distilled water with the same quality as the precipitate, mix well and then adjust the pH value to 10.50-11.50, and then treat it under 300MPa ultra-high static pressure for 60 minutes, then add the precipitate Sodium tripolyphosphate with a mass of 3.0% is mixed and heated in a water bath at a temperature of 45°C for 150 minutes for phosphorylation reaction. After the end, add distilled water 3 times t...

Embodiment 3

[0053] With the above example 1, the difference is:

[0054] Step (2) In the preparation of phosphorylated duck liver crude protein: remove the fascia and fat blocks on the surface of the duck liver, clean it, mix the duck liver and water at a mass ratio of 1:4-8, and place at high speed In the homogenizer, after homogenizing at 6000 rpm for 5 minutes, adjust the pH value to 9.6-9.8, stir for 10 minutes, centrifuge at 6000 rpm for 5 minutes, take the supernatant to adjust the pH value to 4.70-4.90, stir for 10 minutes, Centrifuge for 5 minutes, take the precipitate and add distilled water with the same quality as the precipitate, mix well, adjust the pH value to 10.50-11.50, and then treat it under ultra-high static pressure at 400MPa for 30 minutes, then add pyrophosphoric acid with 4.50% of the mass of the precipitate Sodium, after mixing, heated in a water bath at 70°C for 60 minutes for phosphorylation reaction, after the end, added distilled water 5 times the volume of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com