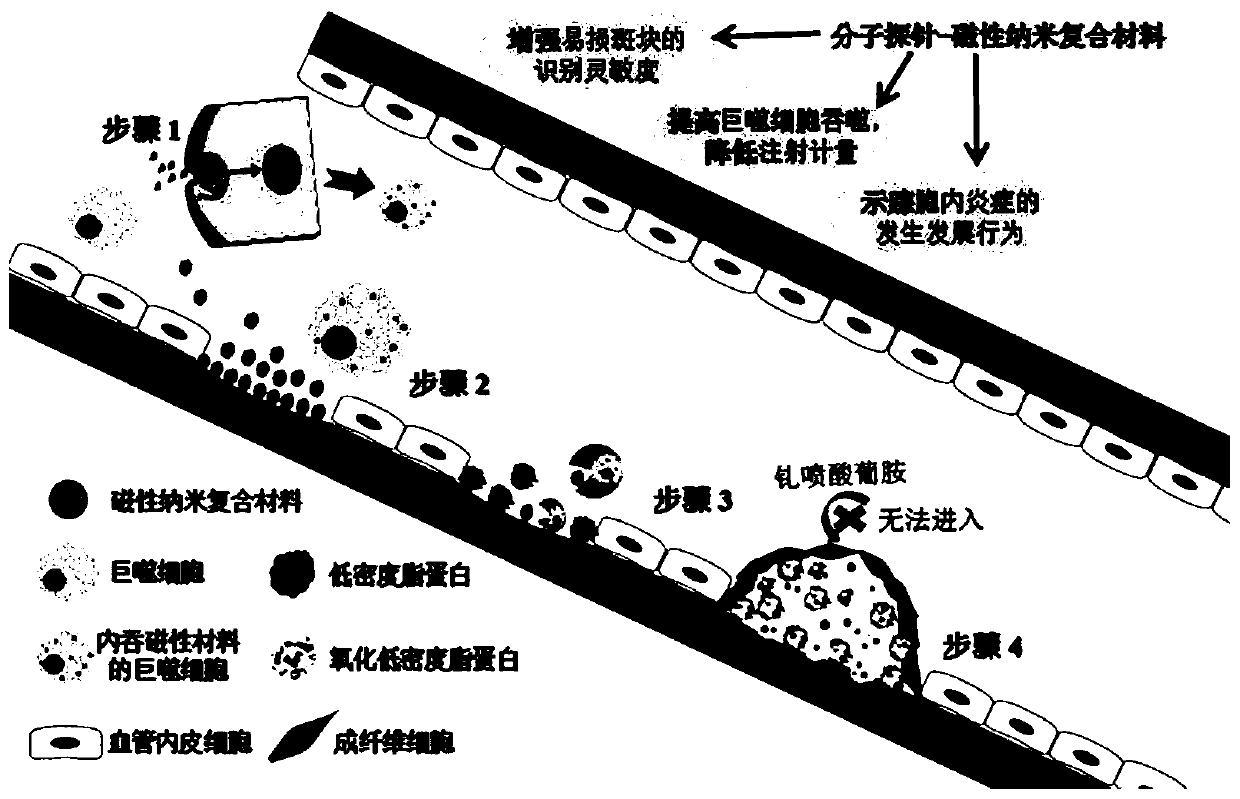

Magnetic nano composite material and preparation method and application of material

A technology of magnetic nano-composite materials, applied in the field of medical materials, can solve the problems of reduced MRIT1 contrast enhancement efficiency and reduced yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

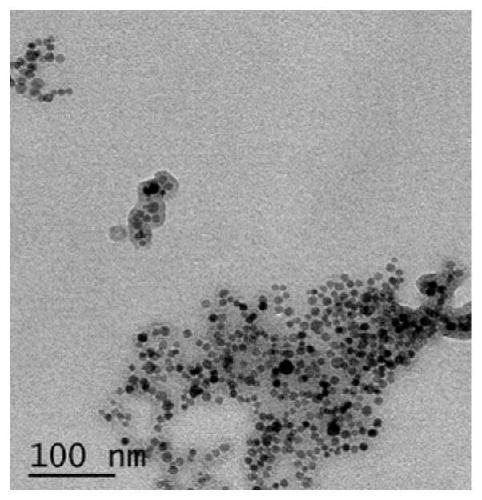

Embodiment 1

[0175] Example 1 Sample 1 # preparation of

[0176] 1. Add 4.325g FeCl 3 .6H 2 O and 2.386 g FeCl 2 .4H 2 O was mixed and dissolved in 300mL water; concentrated nitric acid solution (9ml, 16M) was added dropwise, marked as mixed solution A;

[0177] 2. Quickly add 60 mg of carboxyl-PEG-amino powder to the mixed solution A, mix quickly, and mark it as mixed solution B;

[0178] 3. Rapidly raise the temperature of the mixed solution B to 65°C, and pass it into Ar for protection, add ammonia solution (500ml, volume percentage=20%) dropwise, adjust the pH value to 11, and the solution turns black rapidly;

[0179] 4. Continue to react for 1 hour under stirring condition of 65°C and 500rpm to obtain carboxyl-PEG-amino modified Fe 3 o 4 composite nanoparticles.

[0180] 5. Concentrate the reaction solution in step 4 by suspension steaming to obtain a concentrated solution, and use a 3500 dialysis bag to dialyze the concentrated solution for 72 hours to obtain Fe with an iron...

Embodiment 2

[0183] Example 2 Sample 2 # preparation of

[0184] 1. Add 4.325g FeCl 3 .6H 2 O and 2.386 g FeCl 2 .4H 2 O was mixed and dissolved in 300mL water; concentrated nitric acid solution (9ml, 16M) was added dropwise, marked as mixed solution A;

[0185] 2. Quickly add 60 mg of carboxyl-PEG-amino powder to the mixed solution A, mix quickly, and mark it as mixed solution B;

[0186] 3. Rapidly raise the temperature of the mixed solution B to 85°C, and pass it into Ar for protection, add ammonia solution (500ml, volume percentage=20%) dropwise, adjust the pH value to 11, and the solution turns black rapidly;

[0187] 4. Continue to react for 2 hours under stirring conditions of 85°C and 500rpm to obtain carboxyl-PEG-amino modified γ-Fe 2 o 3 composite nanoparticles.

[0188] 5. Concentrate the reaction solution by suspension steaming to obtain a concentrated solution, and use a 3500 dialysis bag to dialyze the concentrated solution for 72 hours to obtain γ-Fe with an iron conce...

Embodiment 3

[0191] Example 3 Sample 3 # preparation of

[0192] 1. Add 4.325g FeCl 3 .6H 2 O, 2.386g FeCl 2 .4H 2 O and 0.58g ZnSO 4 .7H 2 O was mixed and dissolved in 300mL water; concentrated nitric acid solution (9ml, 16M) was added dropwise, marked as mixed solution A;

[0193] 2. Quickly add 60 mg of carboxyl-PEG-amino powder to the mixed solution A, mix quickly, and mark it as mixed solution B;

[0194] 3. Rapidly raise the temperature of the mixed solution B to 65°C, and pass it into Ar for protection, add ammonia solution (500ml, volume percentage=20%) dropwise, adjust the pH value to 11, and the solution turns black rapidly;

[0195] 4. Continue the reaction for 1 hour at 65°C and 500rpm stirring to obtain carboxyl-PEG-amino modified Zn 0.2 Fe 2.8 o 4 Doped composite nanoparticles.

[0196] 5. Concentrate the reaction solution by suspension steaming to obtain a concentrated solution. Use a 3500 dialysis bag to dialyze the concentrated solution for 72 hours to obtain Zn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Longitudinal relaxation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com