Catalyst for electrochemical water decomposition reaction, and preparation method thereof

A catalyst and water splitting technology, applied in the field of electrochemistry, can solve the problems of low catalytic activity, high cost of raw material scarcity, single catalytic reaction, etc., achieve low reaction temperature, improve electrocatalytic activity and cycle stability, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

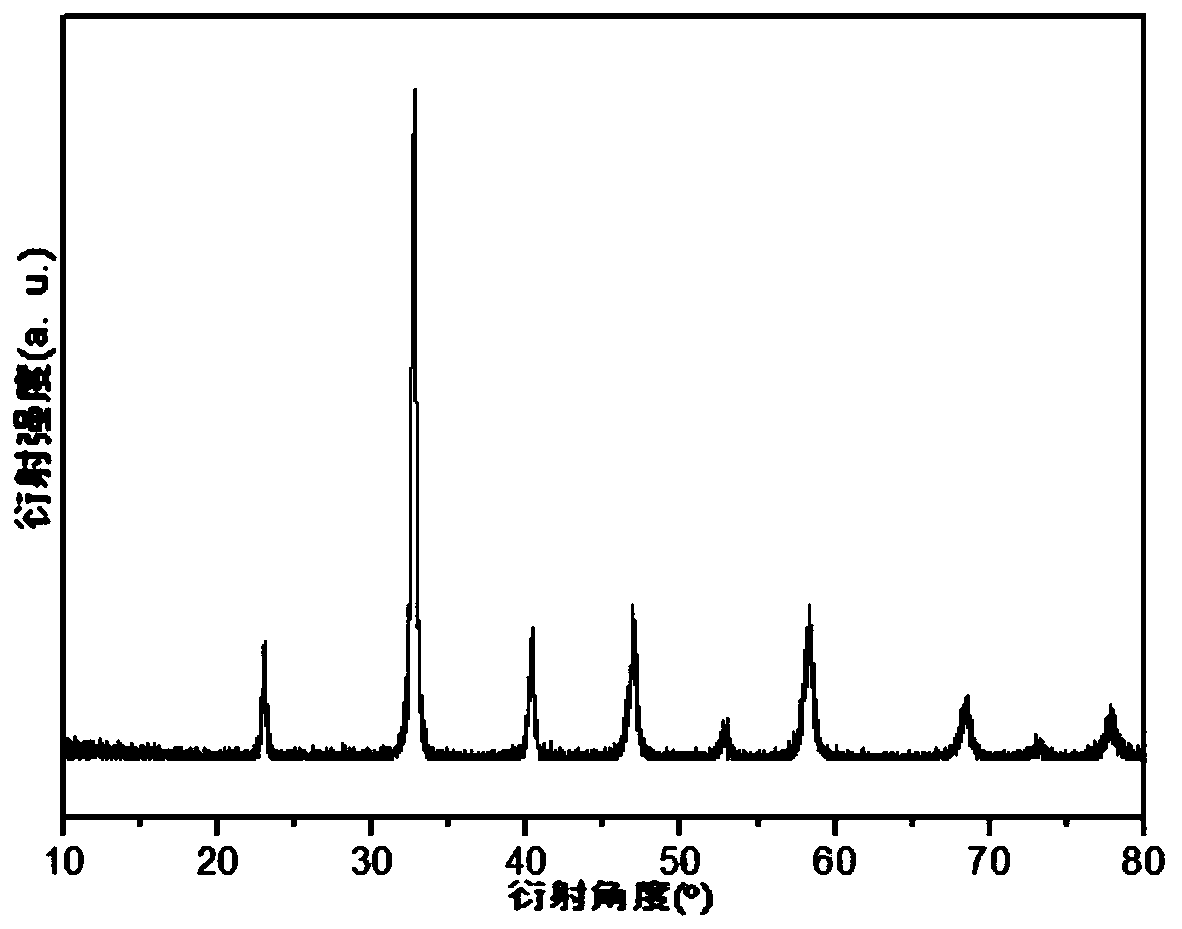

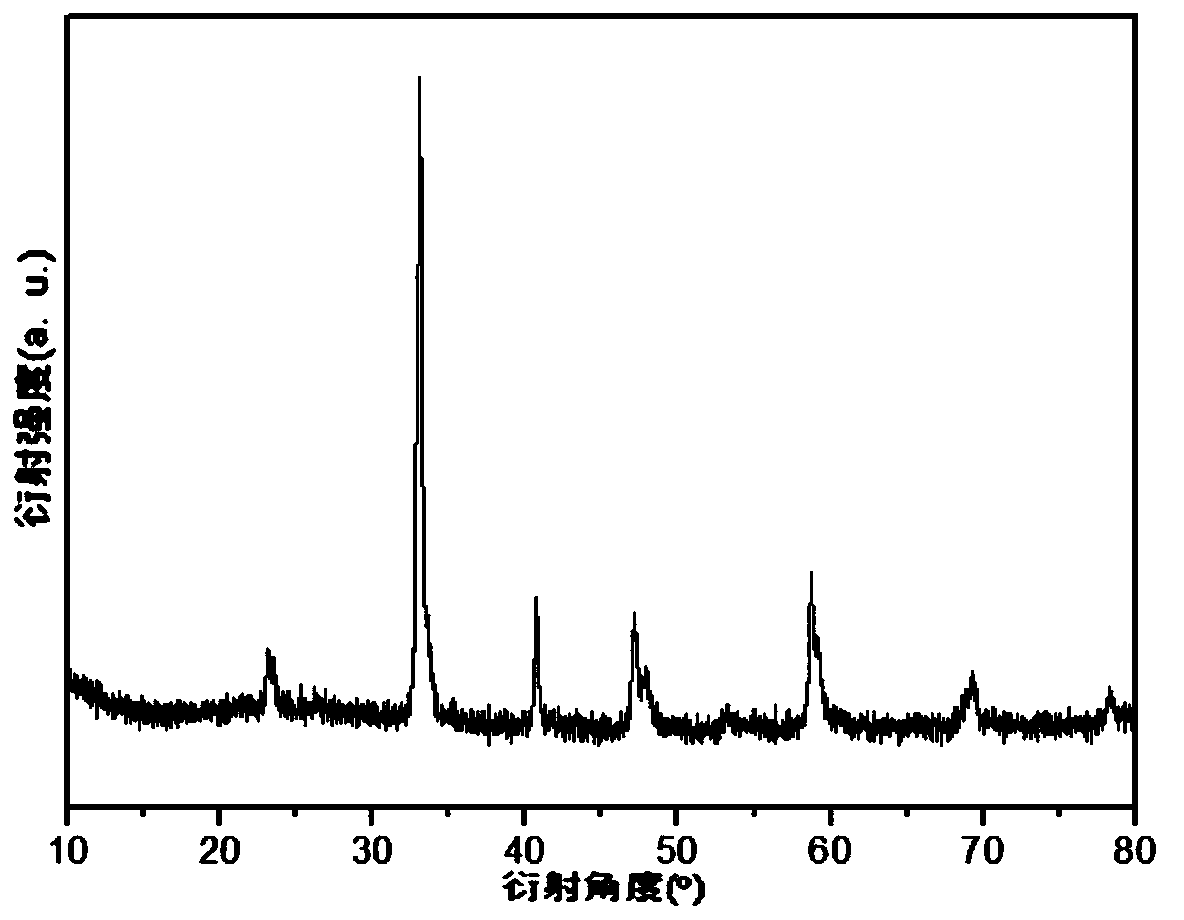

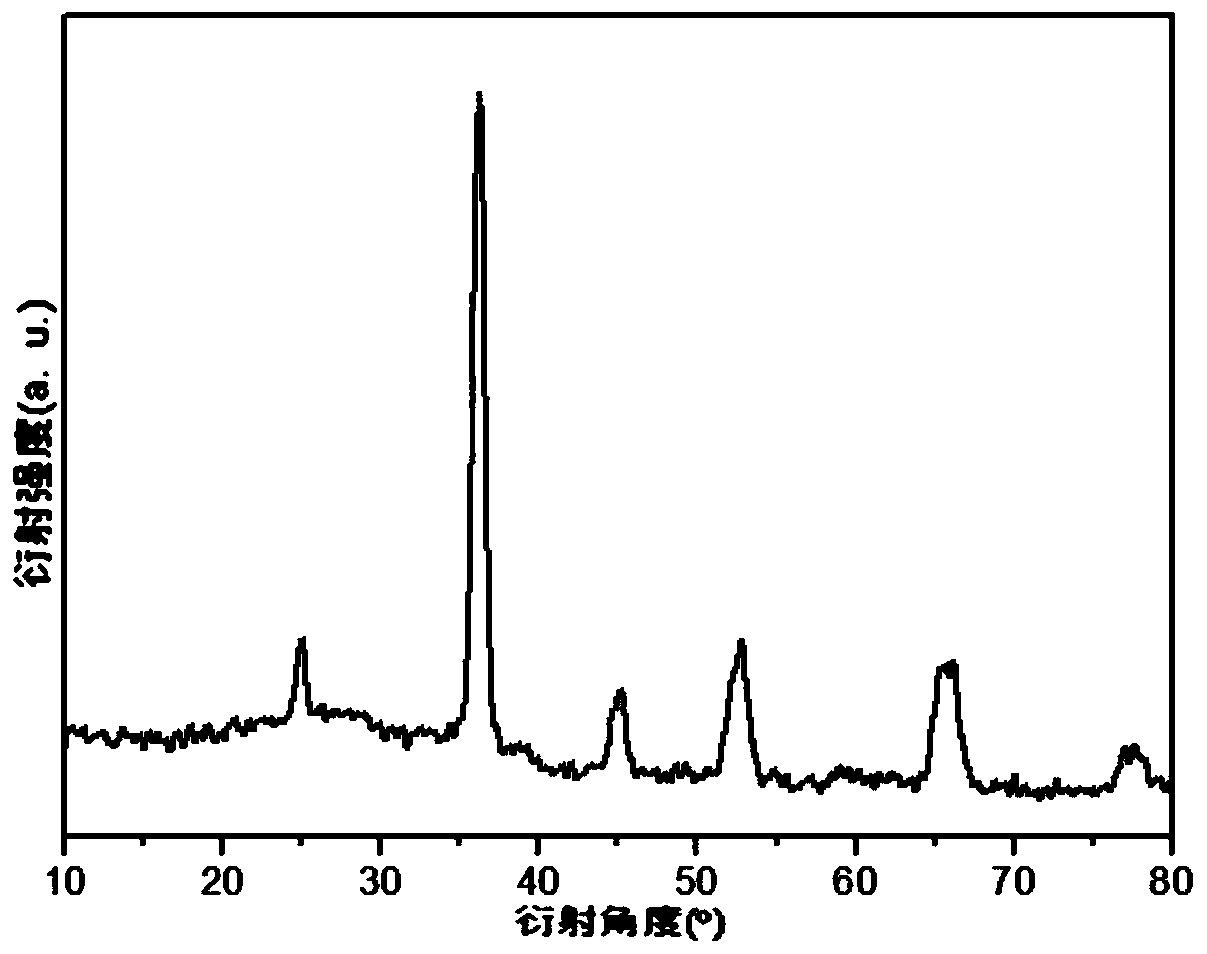

[0030] Specific Embodiment 1: In this embodiment, a catalyst for electrochemical water splitting reaction is prepared by electrospinning with metal ion nitrate as the precursor, denoted as LnBa 1-x Sr x co 2-y Fe y o 5+δ Catalyst; wherein δ is 0-0.5, x is 0-0.5, y is 0-0.4, and Ln is Pr, Eu or Gd.

[0031] δ represents the non-stoichiometric value of oxygen.

specific Embodiment approach 2

[0032] Specific embodiment two: the preparation method of the catalyst for electrochemical water splitting reaction in this embodiment is carried out according to the following steps:

[0033] 1. According to the formula LnBa 1-x Sr x co 2-y Fe y o 5+δ Weigh the raw materials of the catalyst, add the raw materials into N,N-dimethylformamide, stir magnetically at room temperature until completely dissolved, and obtain a metal ion nitrate dispersion; the concentration of the metal ion nitrate dispersion is 0.05 ~0.1mol / L;

[0034] 2. Add polyvinylpyrrolidone to the metal ion nitrate dispersion and continue magnetic stirring to obtain the required precursor solution for electrospinning; the volume ratio of the quality of the polyvinylpyrrolidone to the metal ion nitrate dispersion is 1g : (8 ~ 10) mL;

[0035] 3. Inject the electrospinning precursor solution into a syringe with a stainless steel needle, place the syringe in the electrospinning machine, adjust the electrospi...

specific Embodiment approach 3

[0038] Specific embodiment three: this embodiment is different from specific embodiment two: the raw material described in step one is the nitrate of metal ion in the formula; Wherein Ln represents lanthanide nitrate, specifically Pr(NO 3 ) 3 ·6H 2 O, Eu(NO 3 ) 3 ·6H 2 O or Gd(NO 3 ) 3 ·6H 2 O. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com