Weather-resistant medium-temperature cured epoxy resin adhesive and preparation method thereof

A technology of curing epoxy resin and epoxy resin, which is applied in the field of chemical materials, can solve the problems of poor weather resistance, achieve good temperature resistance and UV aging resistance, meet the needs of use, and overcome the effects of poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

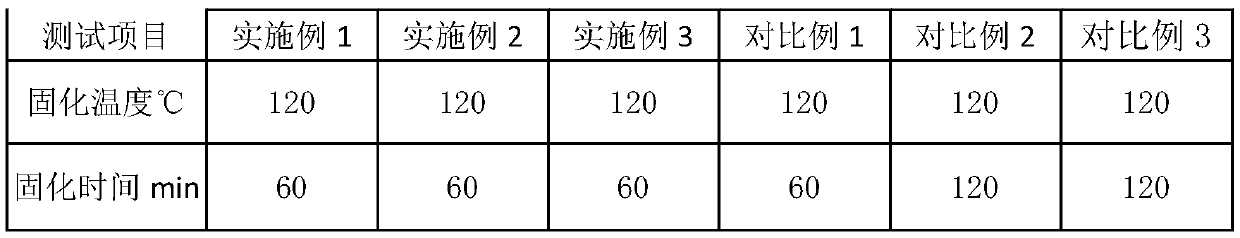

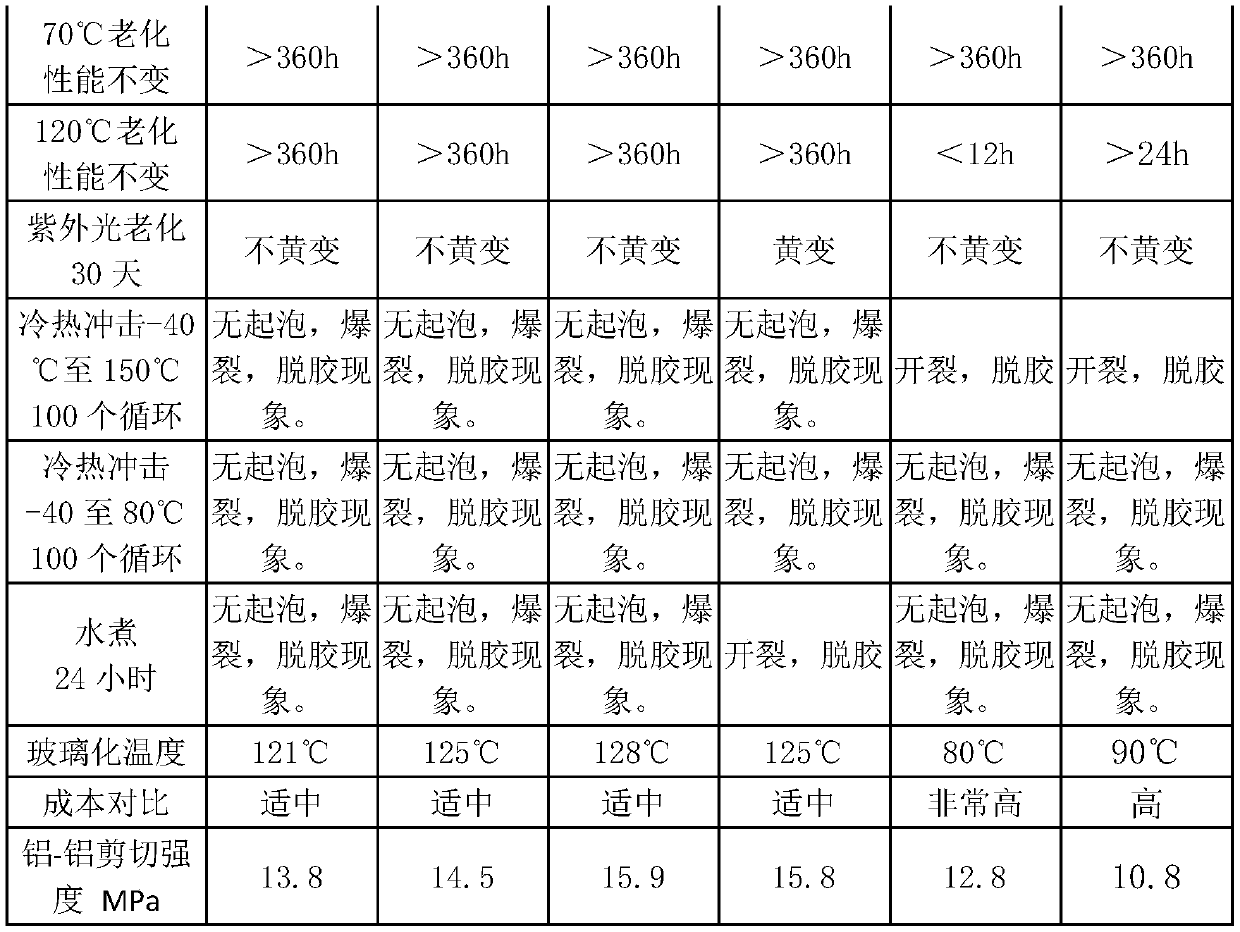

Examples

Embodiment 1

[0024] Embodiment 1: The weather-resistant medium-temperature curing epoxy resin adhesive provided in this embodiment and its preparation method include steps: S1: Take 10g bisphenol A epoxy resin and 20g hydrogenated bisphenol A epoxy resin and mix Uniformly, mechanically stirred for 10 minutes, weighed 3g of carboxyl-terminated CTBN as a toughening agent and added to the mixed resin, mixed evenly under a nitrogen atmosphere, controlled the reaction temperature at 100°C, and cooled to room temperature after a reaction time of 1 hour to obtain a modified Toughening epoxy resin; S2: take by weighing 0.5g ultraviolet absorber, 0.5g antioxidant, 0.5g light stabilizer, 3.5g micropowder dicyandiamide as curing agent, 0.5g2-methylimidazole as accelerator, 1g bentonite , 0.5g fumed silica as a thixotropic agent, then added in order to the modified toughened epoxy resin, mechanically stirred for 30 minutes, to obtain the mixture;

[0025] S3: Weigh 4g butyl glycidyl ether as diluent, ...

Embodiment 2

[0026] Example 2: The weather-resistant medium-temperature curing epoxy resin adhesive and its preparation method provided in this example are basically the same as in Example 1, except that 15g of bisphenol A epoxy resin is weighed as epoxy resin A , 15g hydrogenated bisphenol A epoxy resin as epoxy resin B; Weigh 3g amino-terminated liquid butadiene as toughening agent, weigh 1g UV absorber, 1g antioxidant as stabilizer, weigh 4.5g polymer Propylene glycol diglycidyl ether is used as diluent, and 54g600 mesh activated aluminum hydroxide is taken as filler.

Embodiment 3

[0027] Example 3: The weather-resistant medium-temperature curing epoxy resin adhesive provided in this example and its preparation method are basically the same as in Example 1, except that 20g of bisphenol A epoxy resin is weighed as epoxy resin A , 5g cycloaliphatic epoxy resin, 5g hydrogenated bisphenol A epoxy resin as epoxy resin B; Weigh 1g UV absorber, 1g antioxidant, 0.5g light stabilizer as stabilizer, weigh 4.5g benzene Glycidyl ether was used as a diluent, 53.5g of 600 mesh activated aluminum hydroxide was weighed as a filler, and 1g of γ-glycidoxypropyltrimethoxysilane was used as a coupling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com