Method and equipment for simultaneously removing VOCs and PM2.5

A technology of coolers and compressors, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of combustion waste gas containing dioxins, secondary pollution, and high treatment costs, and achieve easy implementation and no secondary Pollution, the effect of simple operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

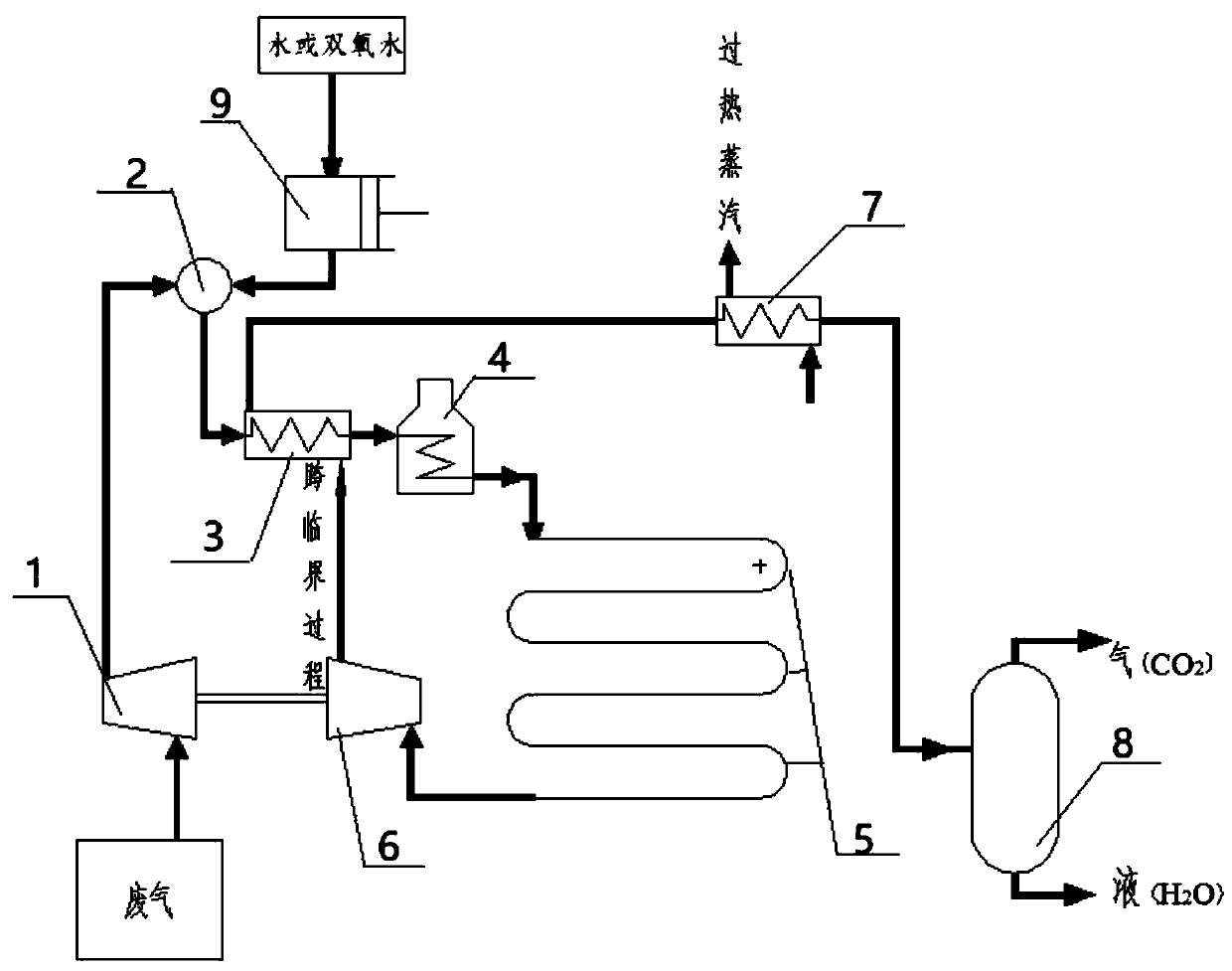

[0046] A device for simultaneously removing VOCs and PM2.5, including a compressor 1, a mixer 2, a preheater-cooler 3, a high-temperature preheater 4, a super / subcritical reactor 5, a turboexpander 6, and a waste heat boiler 7. Gas-liquid separator 8, booster pump 9.

[0047] The gas outlet of the compressor 1 is connected to the feed port of the mixer 2, and the compressor 1 is used for compressing waste gas to be removed. The mixer 2 is connected to the preheater-cooler 3, and the mixer 2 is used for mixing waste gas with water or hydrogen peroxide. The high-temperature preheater 4 is connected to the above-mentioned preheater-cooler 3 , and the super / subcritical reactor 5 is connected to the above-mentioned high-temperature preheater 4 . Turboexpander 6 is connected with described super / subcritical reactor 5, and the fluid that flows out by described super / subcritical reactor 5 drives described turboexpander 6 to do work externally, and described turboexpander 6 The coaxi...

Embodiment 2

[0051] Utilize the device described in embodiment 1 as reaction device, remove the method for VOCs and PM2.5 simultaneously, operation steps are as follows:

[0052] The exhaust gas containing both VOCs and PM2.5 is boosted from normal pressure to 4.0MPa by compressor 1, with a flow rate of 1 million m 3 / h enters the mixer 2; water is pressurized from normal pressure to 4.0MPa through the booster pump 9, and the flow rate is 10.0kg / h, enters the mixer 2 to blend with the exhaust gas, and the resulting mixture enters the preheating-cooler 3 to heat up to 150°C , and then enter the high-temperature preheater 4 to raise the temperature to 600° C., the mixture has a temperature of 600° C. and a pressure of 4.0 MPa, and is a supercritical fluid. The fluid enters the super / subcritical reactor 5 for water oxidation reaction while removing VOCs and PM2.5, and reacts in the super / subcritical reactor 5 for 4 minutes. The high-temperature and high-pressure fluid with a temperature of 6...

Embodiment 3

[0054] Utilize the device described in embodiment 1 as reaction device, remove the method for VOCs and PM2.5 simultaneously, operation steps are as follows:

[0055] The exhaust gas containing both VOCs and PM2.5 is boosted from normal pressure to 40.0MPa through compressor 1, with a flow rate of 100m 3 / h enters the mixer 2; the hydrogen peroxide is boosted from normal pressure to 40.0MPa through the booster pump 9, and the flow rate is 100kg / h, enters the mixer 2 and blends with the exhaust gas, and the resulting mixture enters the preheating-cooler 3 to heat up to 340°C , and then enter the high-temperature preheater 4 to raise the temperature to 700° C., the mixture has a temperature of 700° C. and a pressure of 40.0 MPa, and is a supercritical fluid. The fluid enters the super / subcritical reactor 5 for water oxidation reaction while removing VOCs and PM2.5, and reacts in the super / subcritical reactor 5 for 0.5 min. The high-temperature and high-pressure fluid with a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com