High-dispersion metal nanoparticle/biomass carbon composite electrode material as well as preparation method and application thereof

A metal nanoparticle, biomass carbon technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, electrode, etc., can solve the problem that nano metal particles are easy to agglomerate, affect performance, and have high surface energy. problems, to achieve the effect of improving catalytic performance, low price, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

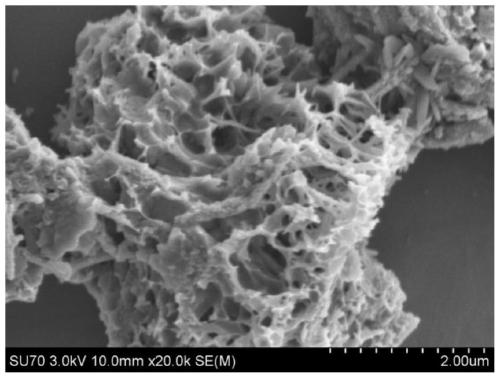

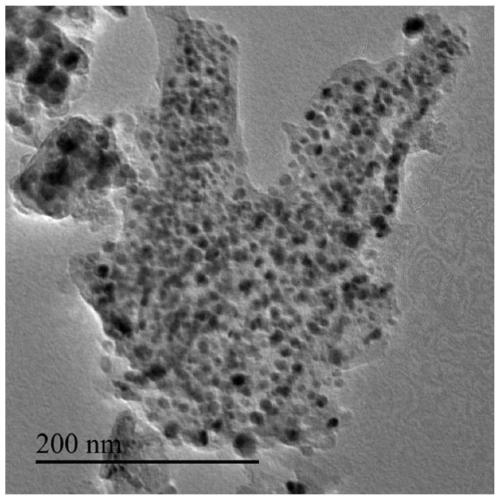

[0031] Soak the loofah with 1.0 mol / L sodium hydroxide solution, wash it with deionized water after standing for 24 hours until the solution is neutral, and remove impurities on the surface of the loofah. Place in an oven, dry at 45°C for 12 hours, and set aside. The appearance of the loofah after alkali washing treatment obtained by scanning electron microscope is as follows: figure 1 shown. The blank loofah presents a three-dimensional cross-linked porous structure. Weigh 2g of processed loofah and put it into a beaker, add 30mL of 0.1mol / L CoCl in turn 2 , 30 mL of 0.2 mol / L dimethylimidazole solution, stirred evenly, and reacted at room temperature for 6 hours. After the reaction is finished, the loofah is washed with ultrapure water, put into a vacuum drying oven, and dried at 45° C. for 12 hours.

[0032] Put the dried loofah in a porcelain boat and place it in a high-temperature tube furnace, with high-purity nitrogen as the protective gas, and the gas velocity is c...

Embodiment 2

[0035]Soak the loofah with 0.8mol / L sodium hydroxide solution, wash it with deionized water after standing for 24 hours until the solution is neutral, and remove impurities on the surface of the loofah. Place in an oven, dry at 45°C for 12 hours, and set aside.

[0036] The blank loofah presents a three-dimensional cross-linked porous structure. Weigh 2g of processed loofah and put it into a beaker, add 30mL of 0.12mol / L CoCl 2 , 30mL of 0.25mol / L dimethylimidazole solution, stirred evenly, and reacted at room temperature for 10 hours. After the reaction is finished, the loofah is washed with ultrapure water, put into a vacuum drying oven, and dried at 45° C. for 12 hours.

[0037] Put the dried loofah in a porcelain boat and place it in a high-temperature tube furnace, with high-purity nitrogen as the protective gas, and the gas velocity is controlled at 25ml / min. The heating rate is 1° C. / min, the calcination temperature is 600° C., and the calcination time is 60 minutes....

Embodiment 3

[0039] Soak the loofah with 0.8mol / L sodium hydroxide solution, wash it with deionized water after standing for 24 hours until the solution is neutral, and remove impurities on the surface of the loofah. Place in an oven, dry at 45°C for 12 hours, and set aside. The blank loofah presents a three-dimensional cross-linked porous structure. Weigh 2g of processed loofah and put it into a beaker, add 30mL of 0.08mol / L CoCl in turn 2 , 30mL of 0.15mol / L dimethylimidazole solution, stirred evenly, and reacted at room temperature for 12 hours. After the reaction is finished, the loofah is washed with ultrapure water, put into a vacuum drying oven, and dried at 45° C. for 12 hours.

[0040] Put the dried loofah in a porcelain boat and place it in a high-temperature tube furnace, with high-purity nitrogen as the protective gas, and the gas velocity is controlled at 25ml / min. The heating rate is 1° C. / min, the calcination temperature is 600° C., and the calcination time is 60 minutes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com