GaAs/AIAs/AIAs Bragg reflector laser

A Bragg reflector and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of affecting the luminous efficiency of light-emitting diodes, the number of high-reflection coating layers, and the difficulty of the process, so as to improve the luminous efficiency, More controllable growth parameters, good monochromatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

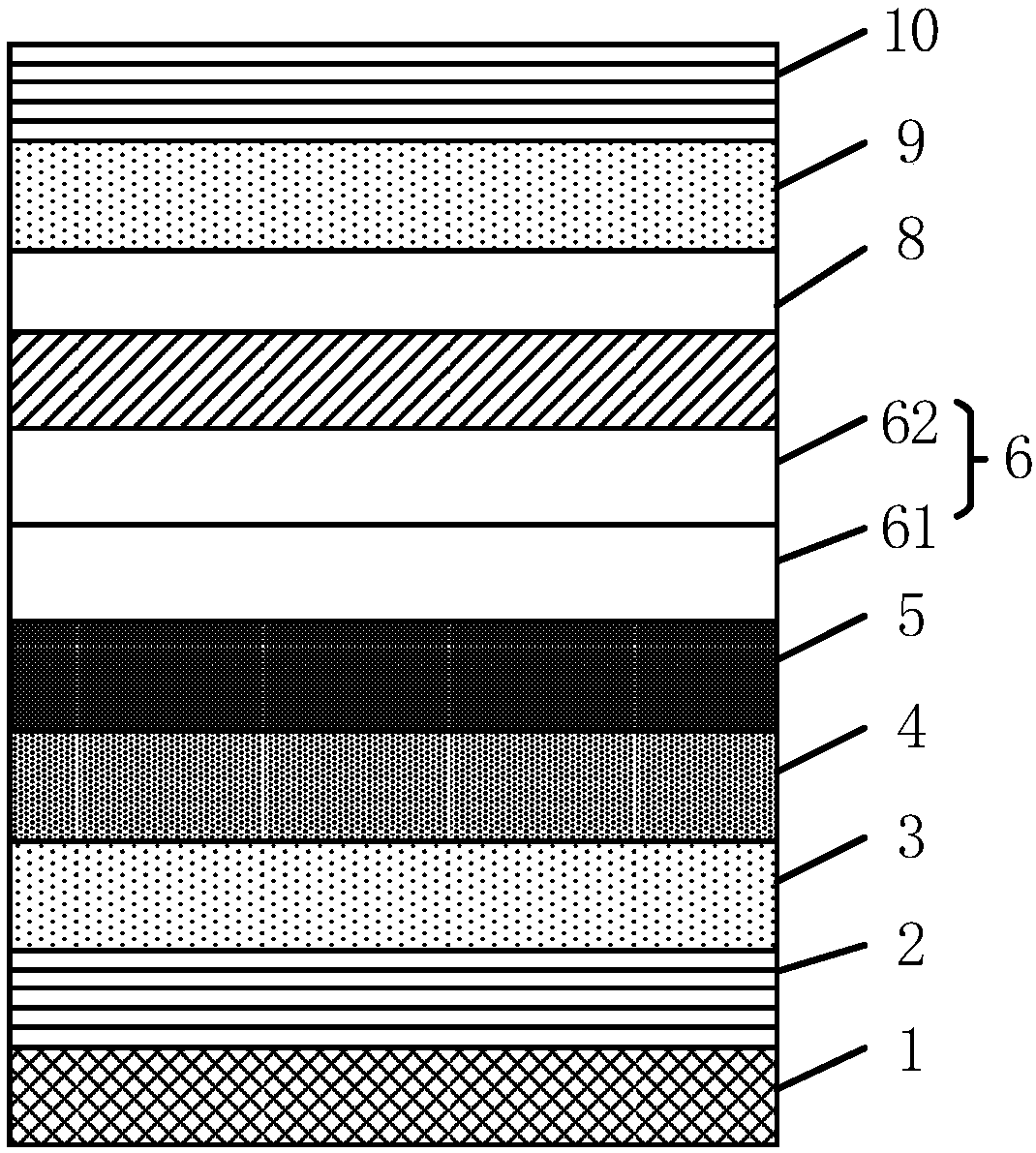

[0031] See figure 1 , figure 1 It is a structural schematic diagram of the GaAs / AIAs / AIAs Bragg mirror laser of the present invention. The structure of the GaAs / AIAs / AIAs Bragg mirror laser of the present invention comprises from bottom to top: a substrate layer 1; a first distributed Bragg mirror layer 2; an n-type Ge semiconductor layer 3; an n-type Ge doped layer 4; Quantum well light-emitting layer 5; electron blocking layer 6; p-type Ge doped layer 7; p-type Ge semiconductor layer 8; second distributed Bragg mirror layer 9; wherein,

[0032] The material of the substrate layer 1 may be sapphire, silicon, silicon carbide, zinc oxide, gallium nitride, aluminum nitride or other materials suitable for crystal epitaxial growth.

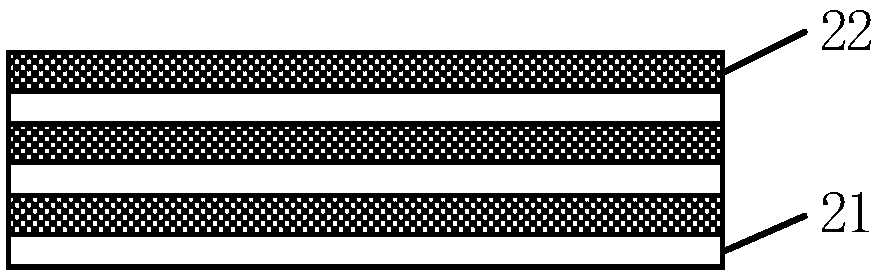

[0033] See figure 2 , figure 2 It is a structural schematic di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com