Method for preparing branched poly(hydroxyethyl methacrylate) by inverse emulsion polymerization at room temperature

A technology of branched poly(hydroxyethyl methacrylate) and inverse emulsion polymerization, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid amides, etc. Long time and other problems, to achieve the effect of simple and stable reaction system, high monomer conversion rate and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

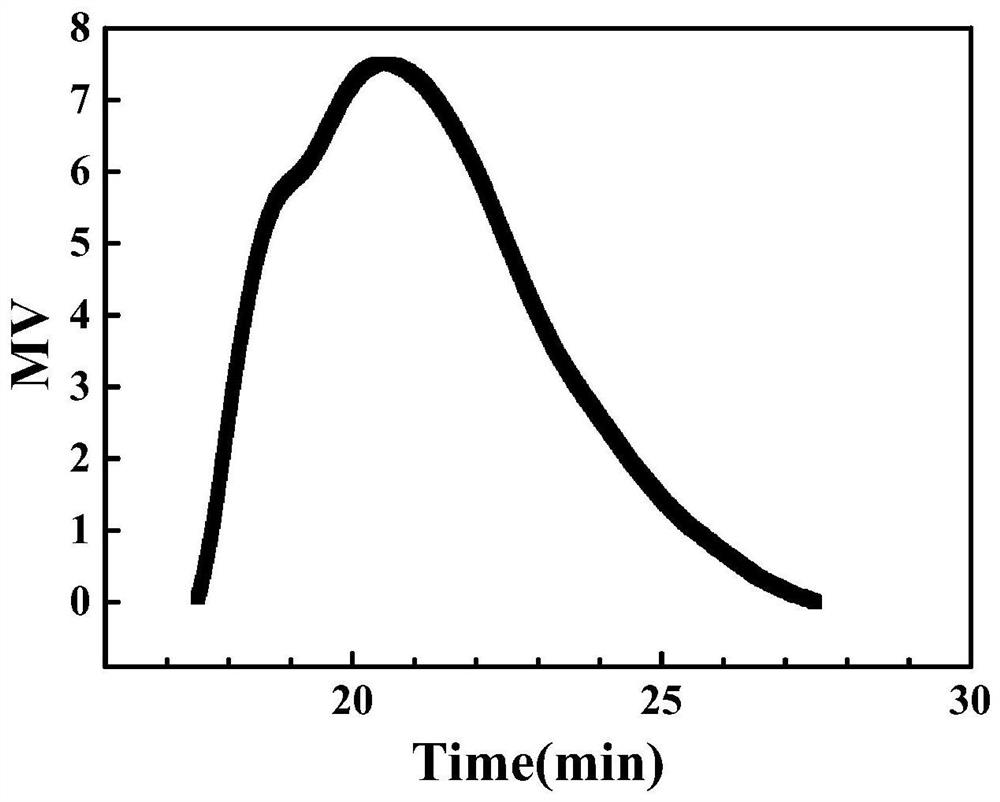

[0025] Hydroxyethyl methacrylate (10.4112 g, 0.0800 mol) was dissolved in water (31.2336 g, 300 wt% methacrylate) hydroxyethyl methacrylate, configured to form a hydroxyethyl methacrylate (25 wt%). The hydroxyethyl methacrylate aqueous hydroxyethyl methacrylate was added to the presence of toluene (41.6448 g, 400 wt% methyl methacrylate), SPAN85 (2.0822 g, 5 wt% toluene), Tween 8 (2.0822 g, 5 wt% toluene), reducing agent In the reaction bottle of MPaema (0.2320 g, 0.0010 mol), stirred and vacumed, the oxidant BPO (0.2422 g, 0.0010 mol) was added, and the reaction was reacted in a 25 ° C water bath for 8 hours, and methacrylic acid was measured. The hydroxyethyl ester conversion is 94.3%. The milk was broken with tetrahydrofuran, dried after three water washing, and then dried after three purification, the polymer was obtained. The analysis is analyzed with the Wushu viscometer with the ubus viscosity. The result is as follows: absolute weight average molecular weight M w.MALLS = 2...

Embodiment 2

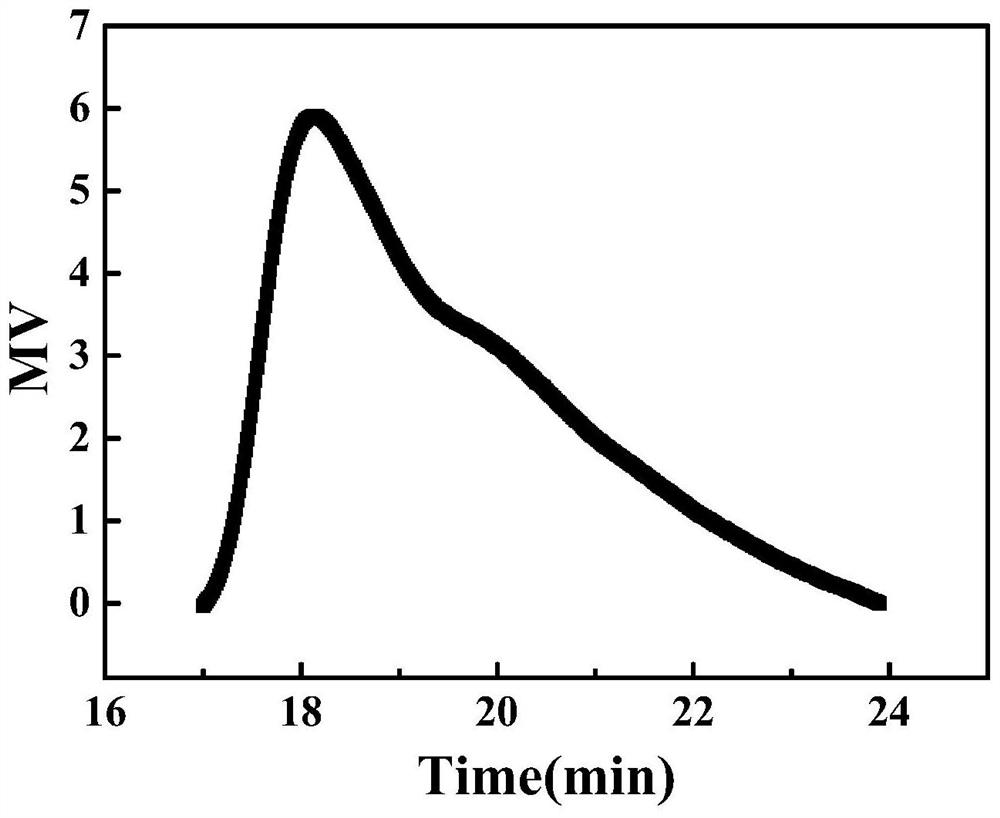

[0030] Methyl methacrylate (13.0140 g, 0.1000 mol) was dissolved in water (39.0420 g, 300 wt% methacrylate) hydroxyethyl methacrylate, configured to form a hydroxyethyl methacrylate (25 wt%). The hydroxyethyl methacrylate aqueous hydroxyethyl methacrylate was added to the plycetol (52.0560 g, 400 wt% methacrylate), SPAN85 (2.6028 g, 5 wt% toluene), Tween 8 (2.6028 g, 5 wt% toluene), reducing agent In the reaction bottle of MPaema (0.2320 g, 0.0010 mol), stirred and vacumed, the oxidant BPO (0.2422 g, 0.0010 mol) was added, and the reaction was reacted in a 25 ° C water bath for 8 hours, and methacrylic acid was measured. The hydroxyethyl ester conversion is 93.7%. The milk was broken with tetrahydrofuran, dried after three water washing, and then dried after three purification, the polymer was obtained. The analysis is analyzed with the Wushu viscometer with the ubus viscosity. The result is as follows: absolute weight average molecular weight M w.MALLS = 2083000g / mol, mean squa...

Embodiment 3

[0033]Methyl methacrylate (15.6168 g, 0.1200 mol) was dissolved in water (46.8504 g, 300 wt% methacrylate) hydroxyethyl methacrylate, configured to form a hydroxyethyl methacrylate (25 wt%). The hydroxyethyl methacrylate aqueous hydroxyethyl methacrylate (62.4672 g, 400 wt% methyl methacrylate), SPAN85 (3.1234 g, 5 wt% toluene), Tween 8 (3.1234 g, 5 wt% toluene), reducing agent In the reaction bottle of MPaema (0.2320 g, 0.0010 mol), stirred and vacumed, the oxidant BPO (0.2422 g, 0.0010 mol) was added, and the reaction was reacted in a 25 ° C water bath for 8 hours, and methacrylic acid was measured. The hydroxyethyl transformation rate was 94.5%. The milk was broken with tetrahydrofuran, dried after three water washing, and then dried after three purification, the polymer was obtained. The analysis is analyzed with the Wushu viscometer with the ubus viscosity. The result is as follows: absolute weight average molecular weight M w.MALLS = 1671000g / mol, mean square rotary radius...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com