Apatite-structure, wide-emission-band and green-light fluorescent powder for white-light LED, and preparation method thereof

An apatite and phosphor technology, which is applied in the field of apatite structure wide emission band green phosphor and its preparation, can solve problems such as low luminous efficiency, achieve high luminous intensity, high color purity, and cheap and easy raw materials the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

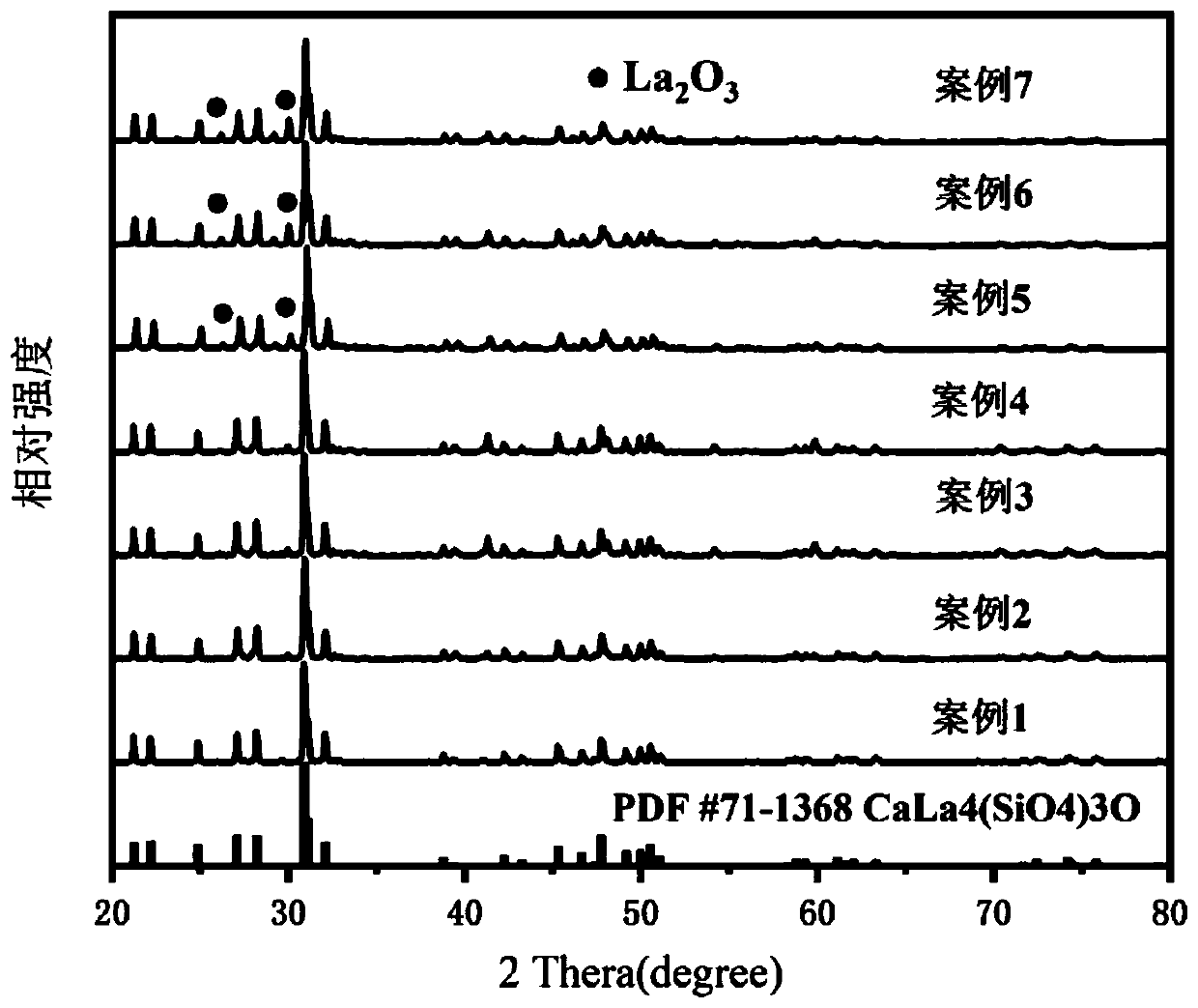

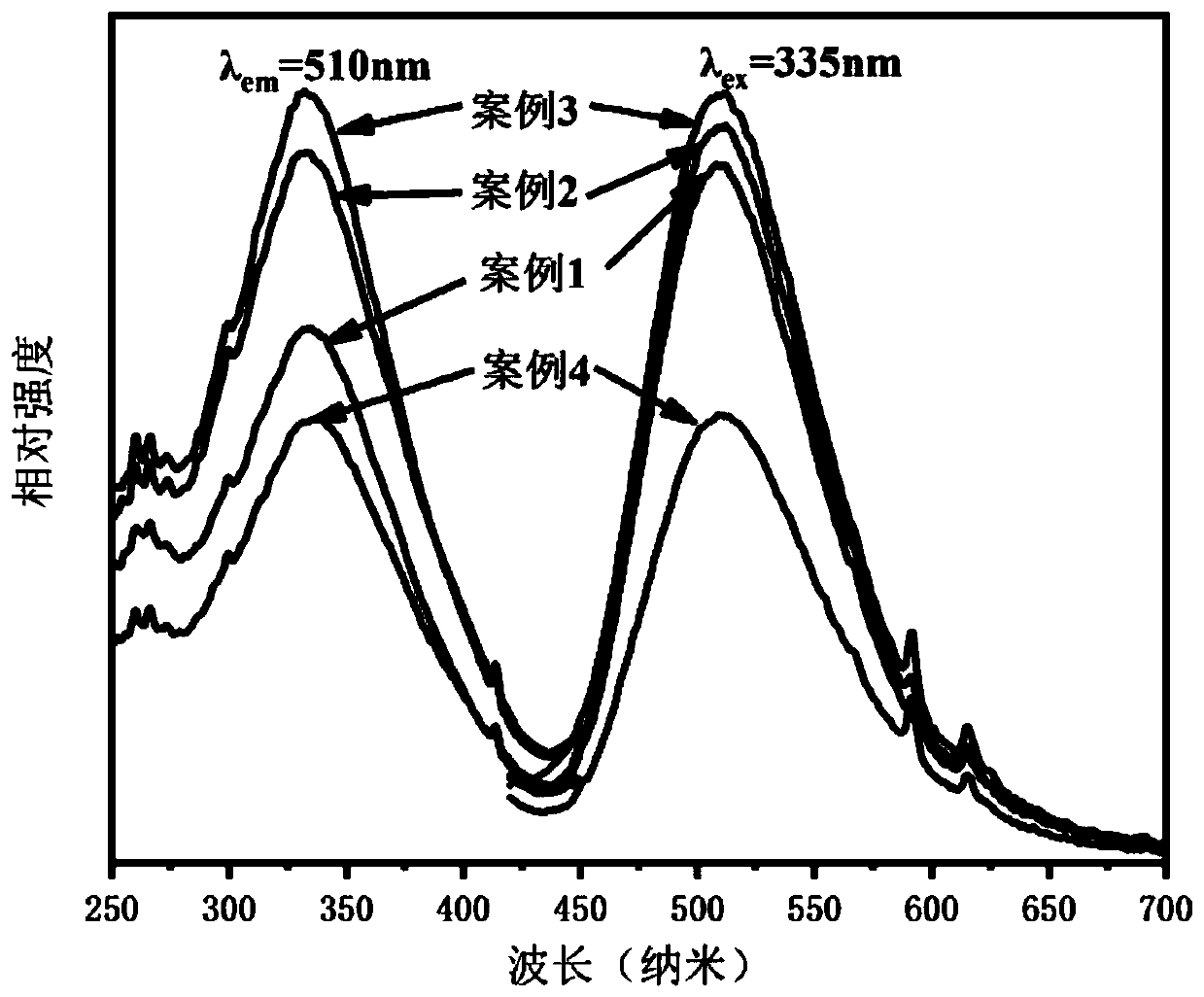

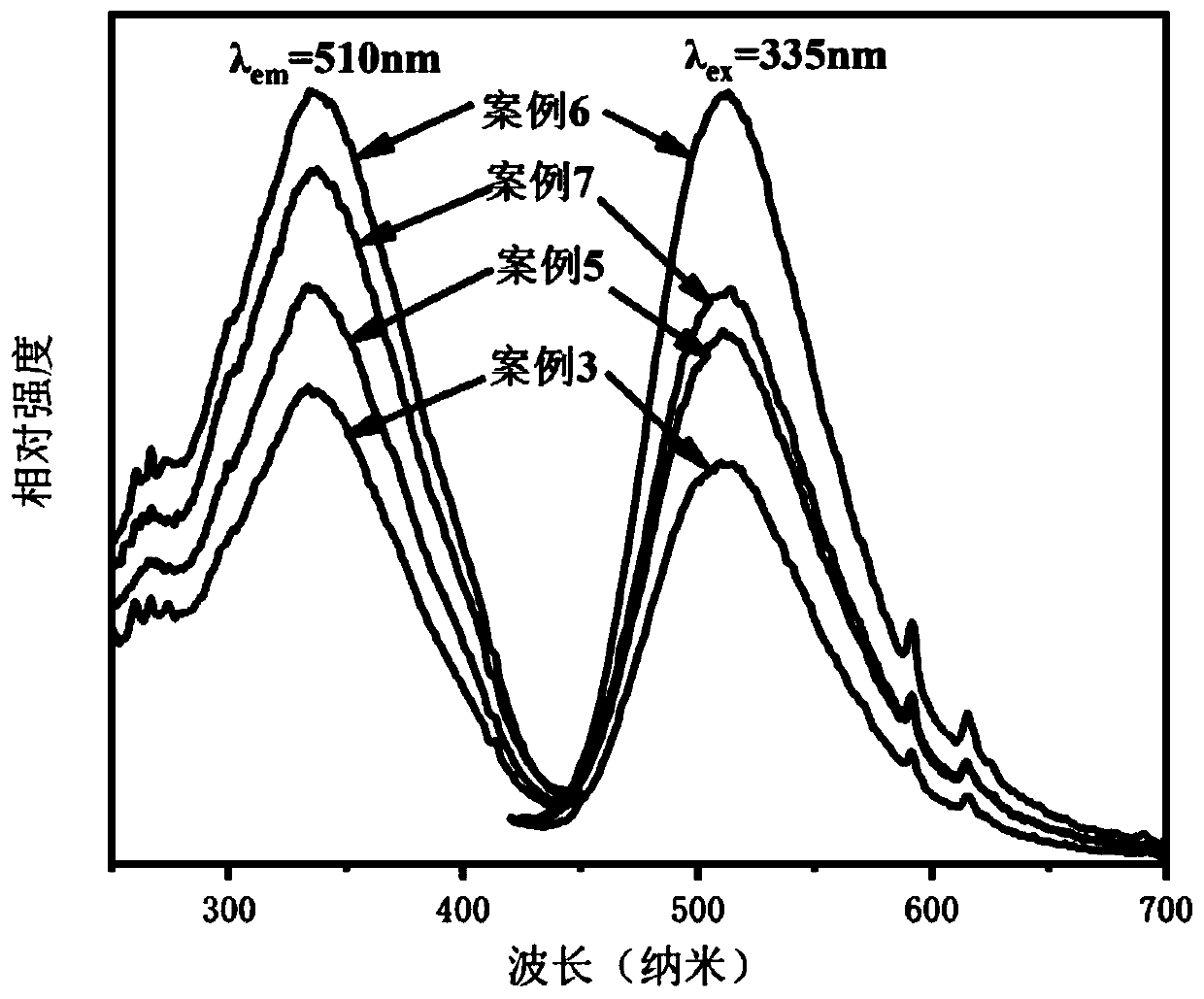

[0022] Example 1: Preparation of Ca 3.99 La 6 (SiO 4 ) 6 O:0.01Eu 2+

[0023] Weigh CaCO in turn 3 (purity 99%) 1.0344g, La 2 o 3 (purity 99.99%) 2.5014g, SiO 2 (purity 99.99%) 0.9222g, Eu 2 o 3 (Purity 99.99%) 0.0045g. Put the above materials in a ball mill and grind them to 4 μm, mix well and put them in a high-purity corundum crucible, and put them into a high-temperature tube furnace, keep the heating rate in the furnace at 3°C / min, at 1350°C Incubate for 6 hours, then cool down to room temperature at a rate of 3°C / min. Maintain a volume fraction of 95% N throughout the furnace 2 with 5% H 2 mixed reducing atmosphere. The product cooled to room temperature was crushed, ball milled, and sieved with a 325-mesh sieve. Then use HNO with a concentration equivalent of 4N in sequence 3 Solution pickling, 4N NH 3 ·H 2 O solution alkaline washing, deionized water washing to neutral. Finally, the above-mentioned washed samples were centrifuged and layered, filtere...

example 2

[0024] Example 2: Preparation of Ca 3.99 La 6 (AlO 4 ) (SiO 4 ) 5 o 0.5 :0.01Eu 2+

[0025] Weigh CaCO in turn 3 (purity 99%) 1.0405g, La 2 o 3 (purity 99.99%) 2.5161g, Al 2 o 3 (purity 99.99%) 0.1312g, SiO 2 (purity 99.99%) 0.7730g, Eu 2 o 3 (Purity 99.99%) 0.0045g. Put the above materials in a ball mill and grind them to 4 μm, mix well and put them in a high-purity corundum crucible, and put them into a high-temperature tube furnace, keep the heating rate in the furnace at 3°C / min, at 1350°C Incubate for 6 hours, then cool down to room temperature at a rate of 3°C / min. Maintain a volume fraction of 95% N throughout the furnace 2 with 5%H 2 mixed reducing atmosphere. The product cooled to room temperature was crushed, ball milled, and sieved with a 325-mesh sieve. Then use HNO with a concentration equivalent of 4N in sequence 3 Solution pickling, 4N NH 3 ·H 2 O solution alkaline washing, deionized water washing to neutral. Finally, the above-mentioned w...

example 3

[0026] Example 3: Preparation of Ca 3.99 La 6 (AlO 4 ) 1.5 (SiO 4 ) 4.5 o 0.25 :0.01Eu 2+

[0027] Weigh CaCO in turn 3 (purity 99%) 1.0435g, La 2 o 3 (purity 99.99%) 2.5235g, Al 2 o 3 (purity 99.99%) 0.1973g, SiO 2 (purity 99.99%) 0.6978g, Eu 2 o 3 (Purity 99.99%) 0.0045g. Put the above materials in a ball mill and grind them to 4 μm, mix well and put them in a high-purity corundum crucible, and put them into a high-temperature tube furnace, keep the heating rate in the furnace at 3°C / min, at 1350°C Incubate for 6 hours, then cool down to room temperature at a rate of 3°C / min. Maintain a volume fraction of 95% N throughout the furnace 2 with 5% H 2 mixed reducing atmosphere. The product cooled to room temperature was crushed, ball milled, and sieved with a 325-mesh sieve. Then use HNO with a concentration equivalent of 4N in sequence 3 Solution pickling, 4N NH 3 ·H 2 O solution alkaline washing, deionized water washing to neutral. Finally, the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com