Preparation method of Fe-g-C3N4 multifunctional nano composite material

A nanocomposite material, fe-g-c3n4 technology, applied in the field of water treatment, can solve the problems of small spectral response range, large forbidden band width, poor visible light absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

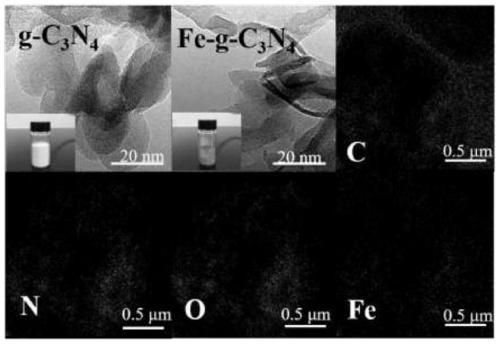

Embodiment 1

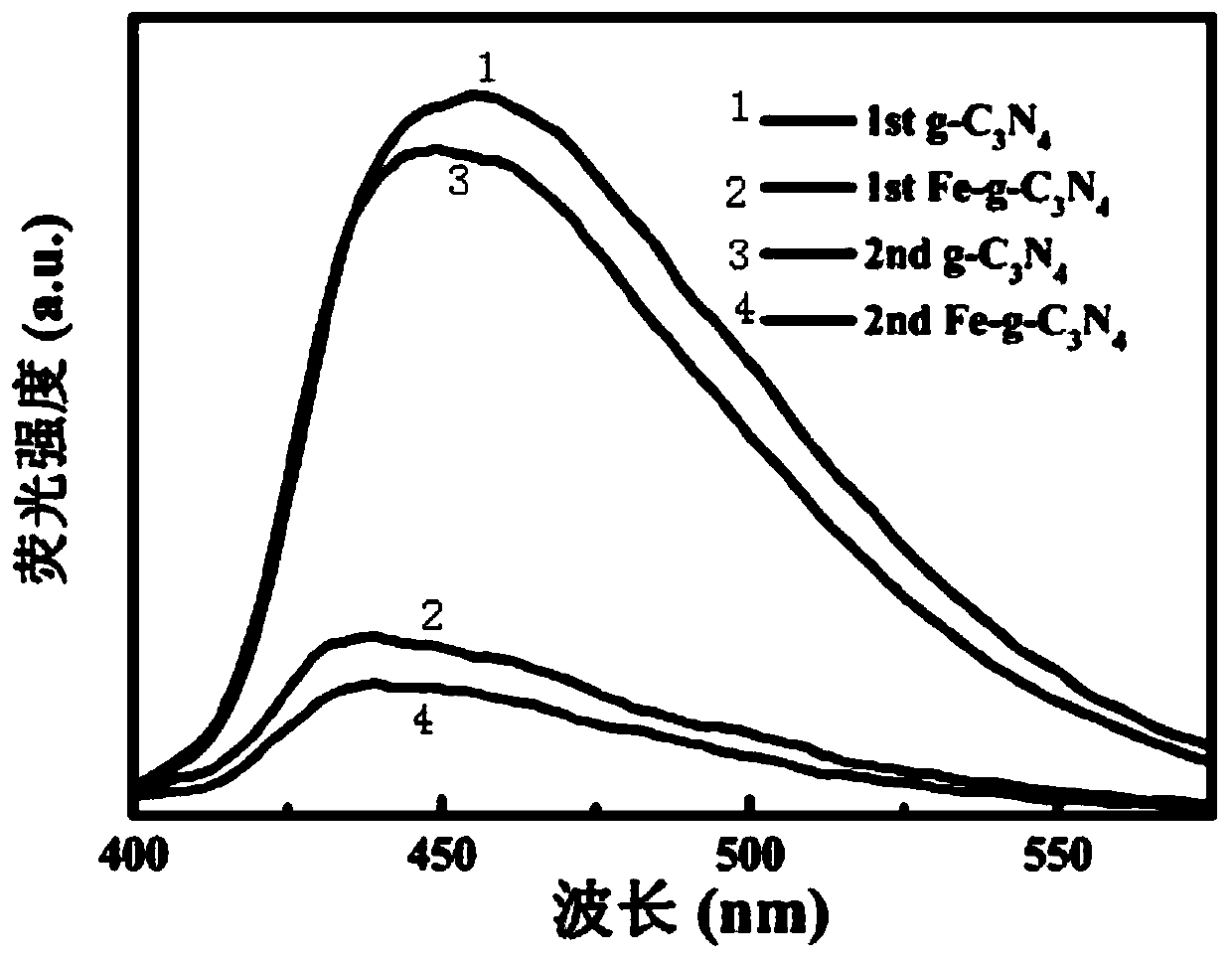

[0020] Example 1: 10 g of urea and 2.8 g of ferric chloride hexahydrate were dissolved in absolute ethanol, stirred thoroughly, and evaporated in a water bath to obtain a complex. The obtained composite was calcined once in a muffle furnace: the temperature was raised to 550°C and kept for 4 hours at a heating rate of 5°C / min, cooled naturally to room temperature, and then ground to an evenly distributed powder. After cleaning in a certain way, flake Fe-g-C 3 N 4 Complex (recorded as 1st Fe-g-C 3 N 4 ). The resulting flake Fe-g-C 3 N 4 The compound is placed in a tube furnace, and is subjected to secondary calcination thermal stripping treatment at 520 ° C for 2 h under an argon atmosphere, with a heating rate of 10 ° C / min for 2 h. Fe-g-C is obtained after cooling and grinding. 3 N 4 Nanocomposite (denoted as 2nd Fe-g-C 3 N 4 ).

[0021] Carry out primary and secondary calcinations without adding ferric chloride hexahydrate according to the same method as above to...

Embodiment 2

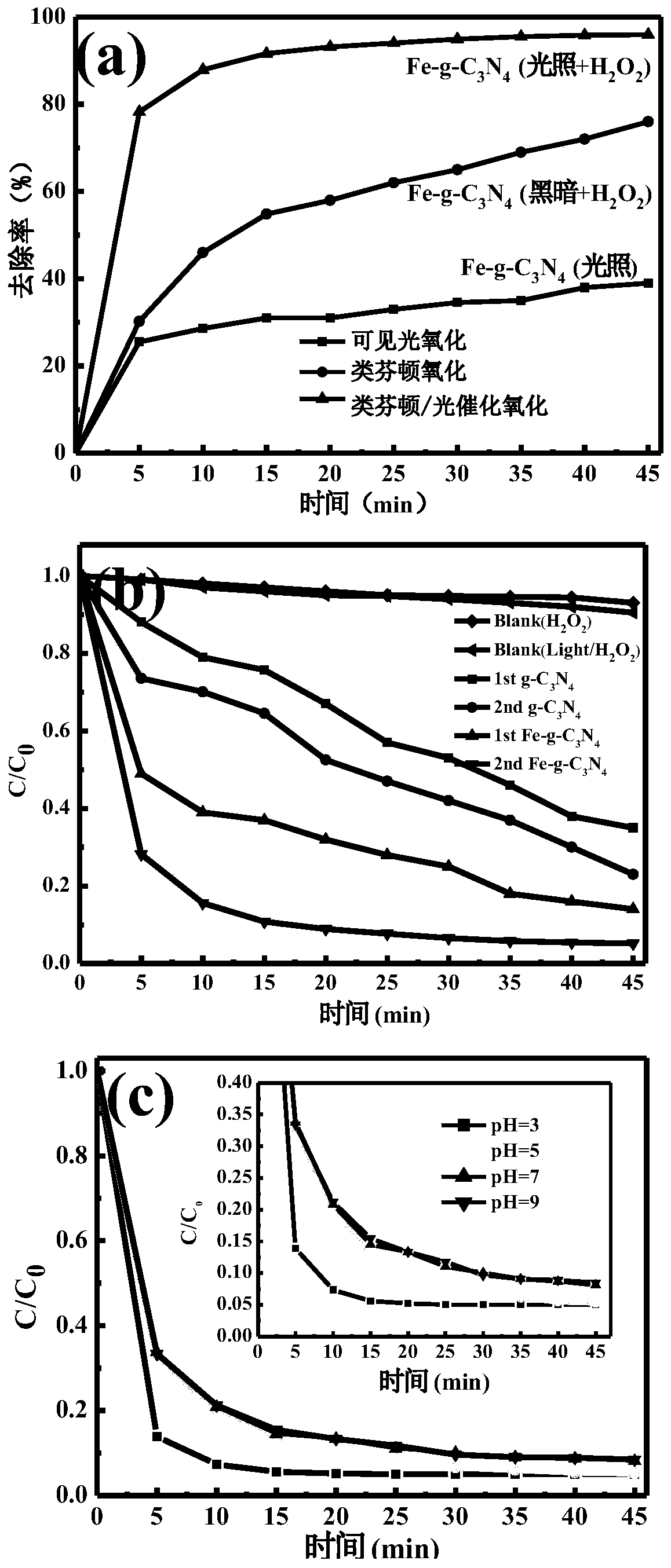

[0025] Embodiment 2: the prepared Fe-g-C 3 N 4 The nanocomposite was used as a catalyst to carry out test experiments under different systems. The main steps are as follows: 20mg of catalyst was added to 100mL of rhodamine B solution with a concentration of 10mg / L, and it was darkly adsorbed for 40min to achieve adsorption equilibrium, and then the xenon lamp light source was turned on to a 300W xenon lamp , filter out the ultraviolet light with a 420nm filter. Add 30% H 2 o 2 (1mmol / L) for degradation reaction; sampling every 5min, after filtering through a 0.45μm filter membrane, measure the absorbance of Rhodamine B at a wavelength of 555nm with a UV spectrophotometer.

[0026] image 3 In a is the addition of an equal amount of 2nd Fe-g-C 3 N 4 Rhodamine B degradation effect after catalyst in visible light catalytic oxidation, Fenton-like oxidation and Fenton-like / photocatalytic oxidation. It can be seen that the degradation rates of Rhodamine B by photocatalytic ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com