Magnesium hydride hydrolysis hydrogen production device and control method thereof

A technology for hydrogen production and magnesium hydride by hydrolysis, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as easy blockage of pipelines, difficult to accurately add materials, and reduced reaction completeness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

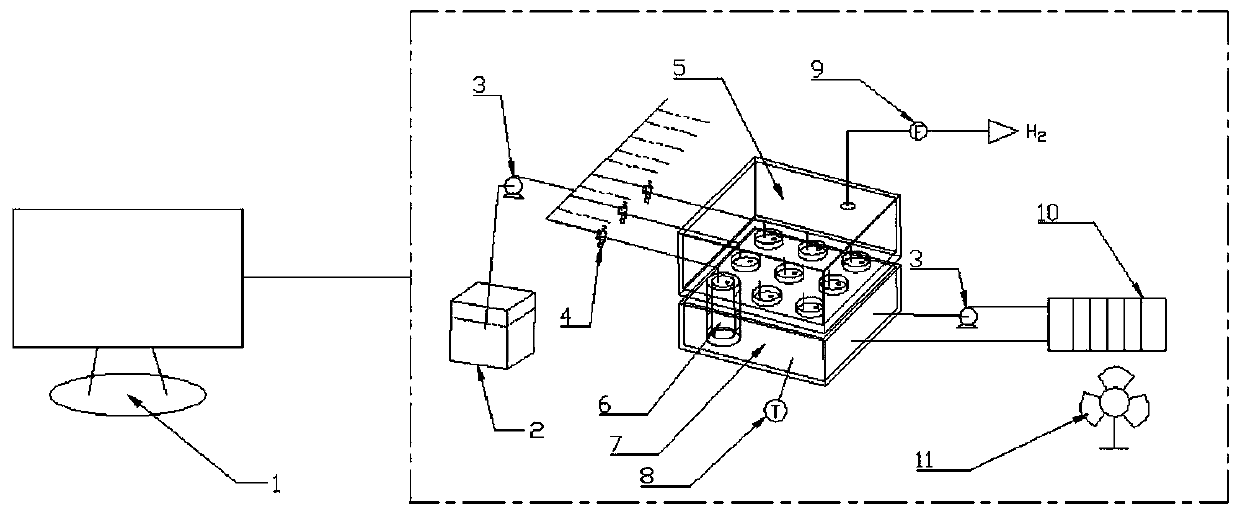

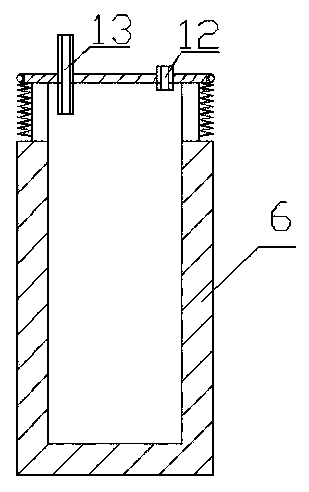

[0024] Example 1, such as figure 1 , 2 As shown, a hydrolysis hydrogen production device includes a controller, a water tank, a circulating pump, a valve, a gas storage room, and 6 reactors. The 6 reactors are connected to the bottom of the gas storage room through threads, and the connection is provided with a gas outlet. and the water inlet, the bottoms of the six reactors are installed in the water tank, and the water tank is in contact with the bottom of the gas storage chamber; a heat exchanger is arranged in the water tank, and the heat exchanger is connected to a radiator, and the radiator is provided with a fan. There is a temperature sensor; the water tank is connected to the valve through the circulating pump, the controller controls the valve to be connected to the reactor, and the gas storage chamber has a hydrogen outlet; a mass flow meter is installed on the hydrogen outlet pipeline; the hydrogen outlet pipeline is connected to the cooler and the dryer in turn ....

Embodiment 2

[0025] Embodiment 2, the control method of hydrolysis hydrogen production device, hydrolysis hydrogen production device is equipped with 100 reactors, and each reactor volume is 50ml, and each reactor adds solid 12 grams MgH Powder, when needing 100 liters of hydrogen, controller 1 Open the corresponding valves of the 5 reactors through the driving mechanism, a certain amount of water enters the reactors through the pipeline, and the hydrogen generated by each reactor enters the gas storage chamber through the filter membrane, and then obtains the required 100 liters of hydrogen through the hydrogen outlet.

Embodiment 3

[0026] Embodiment 3, the control method of hydrolysis hydrogen production device, hydrolysis hydrogen production device is equipped with 20 reactors, and each reactor volume is 150ml, and each reactor adds solid 50 grams MgH Powder, when needing 160 liters of hydrogen, controller 1 Open the corresponding valves of the two reactors through the driving mechanism, a certain amount of water enters the reactors through the pipeline, and the hydrogen produced by each reactor enters the gas storage chamber through the filter membrane, and then obtains the required 160 liters of hydrogen through the hydrogen outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com