Low-dielectric-constant heat-conducting silica gel sheet and preparation method thereof

A technology of low dielectric constant and thermally conductive silica gel sheet, which is applied in chemical instruments and methods, heat exchange materials, etc., and can solve problems such as difficult industrial production, complicated process, and inability to fill gaps in electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In addition, the present invention also provides a preparation method of the low dielectric constant thermally conductive silica gel sheet, comprising the following steps:

[0037]S1. Under the condition of 100-180°C, use silane coupling agent to treat the low dielectric constant heat-conducting powder for 2-5 hours;

[0038] S2. At 50-100°C, add vinyl silicone oil to the processed powder and stir for 1-2 hours; after it is uniform, drop to room temperature and add inhibitors, rubber reinforcement additives, and hydrogen-containing silicone oil to continue stirring 0.5-1.5 hours; then add the platinum catalyst and stir evenly, and vacuumize for 0.5-1.5 hours; after pressing to the required thickness, cure at 100-200°C to obtain the low dielectric constant thermally conductive silica gel sheet.

[0039] Further, in step S1, the low dielectric constant thermally conductive powder is processed by using a kneader, a planetary mixer, a dynamic mixer, a high-speed disperser o...

Embodiment 1

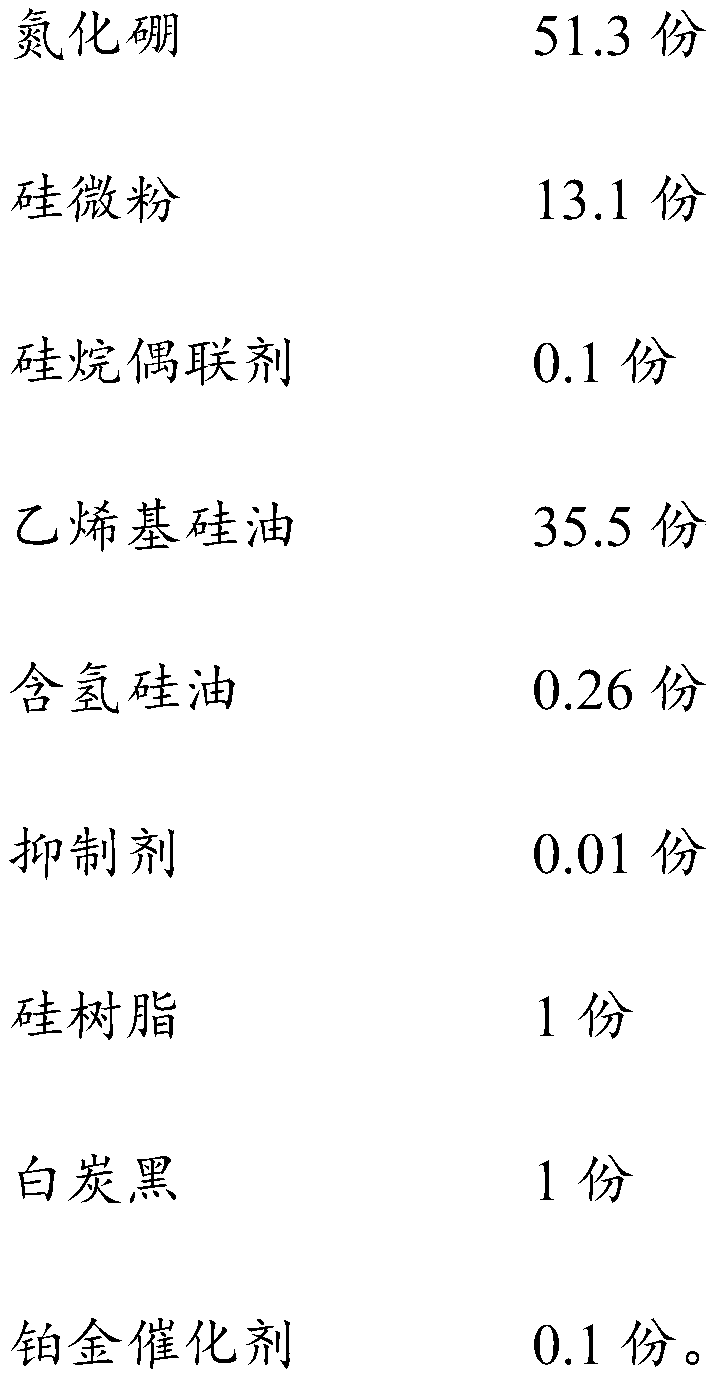

[0041] This embodiment provides a low dielectric constant thermally conductive silica gel sheet, the formula of which includes the following components by weight:

[0042]

[0043] The preparation method of the low dielectric constant thermally conductive silica gel sheet of the present embodiment is as follows:

[0044] 1. Use a kneader to treat the mixed powder of boron nitride, silicon micropowder and white carbon black with silane coupling agent KBM5210 at 120°C for 2 hours. The dielectric constant of boron nitride is 3.2, and the average particle size is 180um. Silica powder chooses a powder with a dielectric constant less than 3, and the average particle size is 2um; the specific surface area of white carbon black is 150m 2 / g.

[0045] 2. At 50°C, add vinyl silicone oil with a viscosity of 1000cps and silicone resin with a viscosity of 6000cps to the processed powder and stir for 1 hour; after it is uniform, drop to room temperature and add the inhibitor 3-methyl-...

Embodiment 2

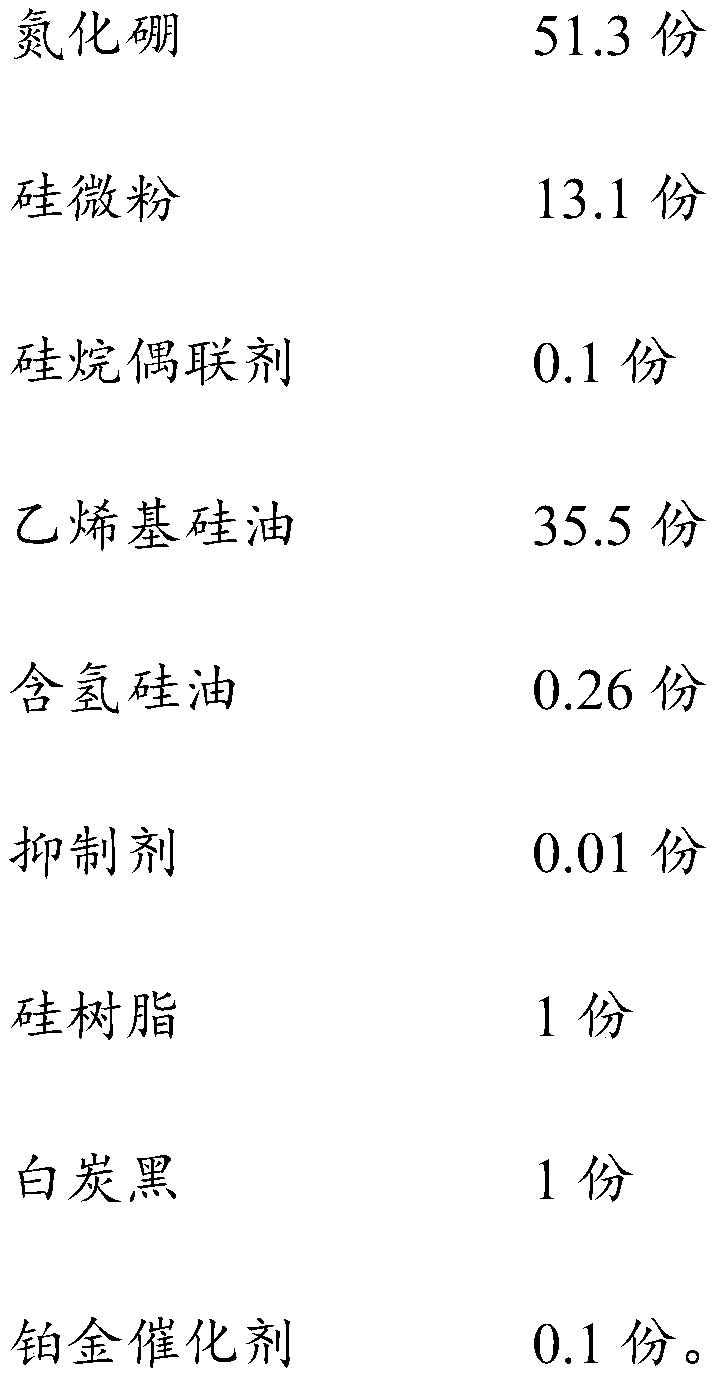

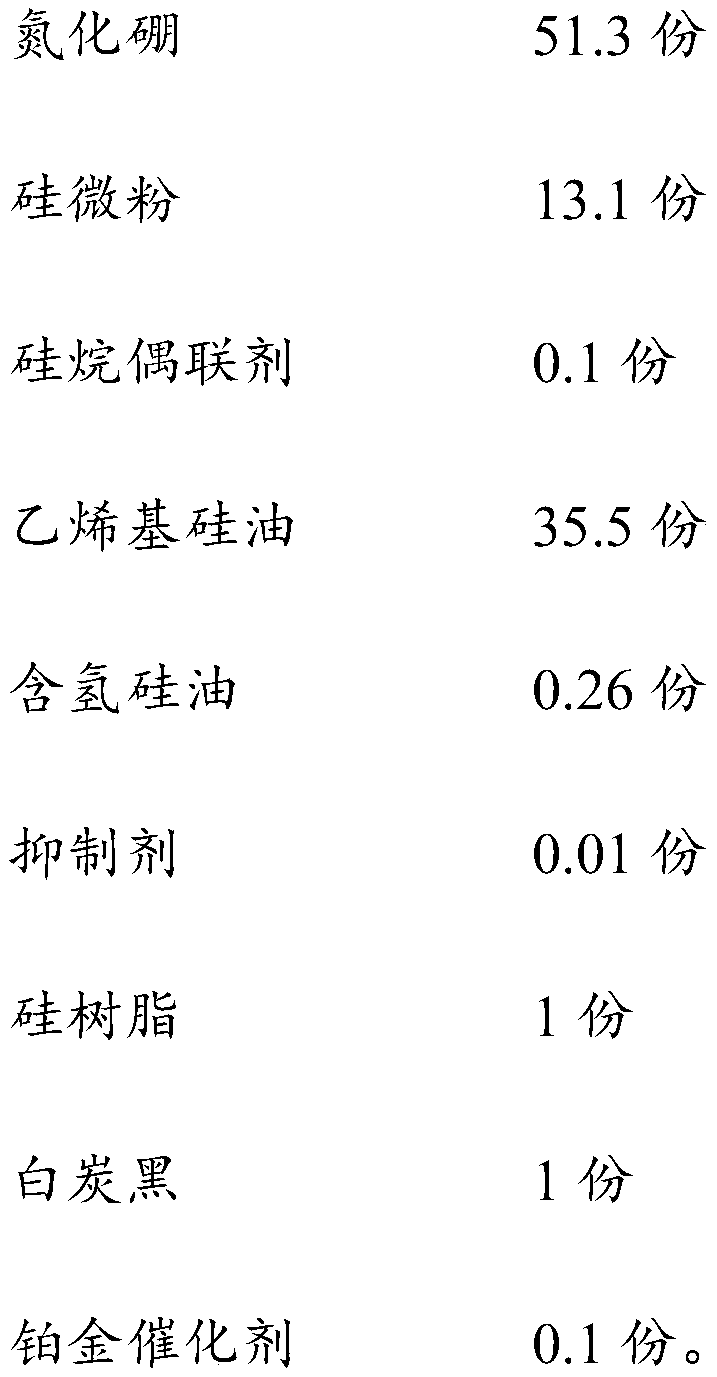

[0048] This embodiment provides a low dielectric constant thermally conductive silica gel sheet, the formula of which includes the following components by weight:

[0049]

[0050] 1. Using a kneader, use the silane coupling agent KBM3103C to treat the mixed powder of boron nitride and aluminum hydroxide for 2 hours at 120°C; the dielectric constant of boron nitride is 3.2, the average particle size is 100um, and aluminum hydroxide Dielectric constant 3.4, average particle size 50um;

[0051] 2. At 50°C, add vinyl silicone oil with a viscosity of 2000cps to the processed powder, and stir for 1 hour; after it is uniform, drop to room temperature and add silicone resin with a viscosity of 6000cps and inhibitor 3,5-dimethyl Base-1-hexyn-3-ol and hydrogen-containing silicone oil with a viscosity of 50cps continue to stir for 0.5 hours; then add a platinum catalyst with a platinum content of 3000ppm and stir evenly, and vacuumize for 0.5 hours; after pressing to the required thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com