Composite material and preparation method thereof

A composite material and quantum dot technology, which is applied in the field of composite materials and its preparation, can solve the problems of carbon quantum dot fluorescence quenching and low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

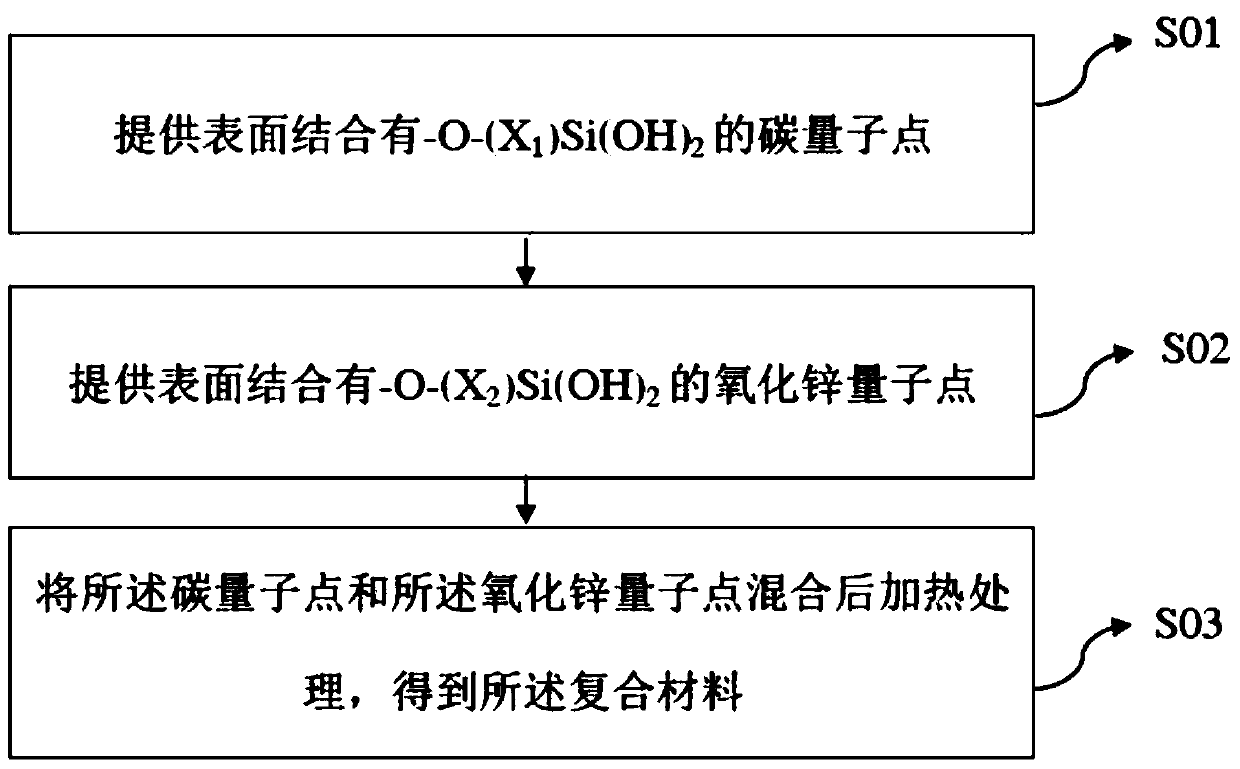

[0024] On the other hand, an embodiment of the present invention provides a method for preparing a composite material, such as figure 1 shown, including the following steps:

[0025] S01: Provide surface binding with -O-(X 1 )Si(OH) 2 carbon quantum dots;

[0026] S02: Provide surface binding with -O-(X 2 )Si(OH) 2 Zinc oxide quantum dots;

[0027] S03: heat treatment after mixing the carbon quantum dots and the zinc oxide quantum dots to obtain the composite material;

[0028] Among them, X 1 and x 2 independently selected from hydrocarbyl or hydrocarbyl derivatives.

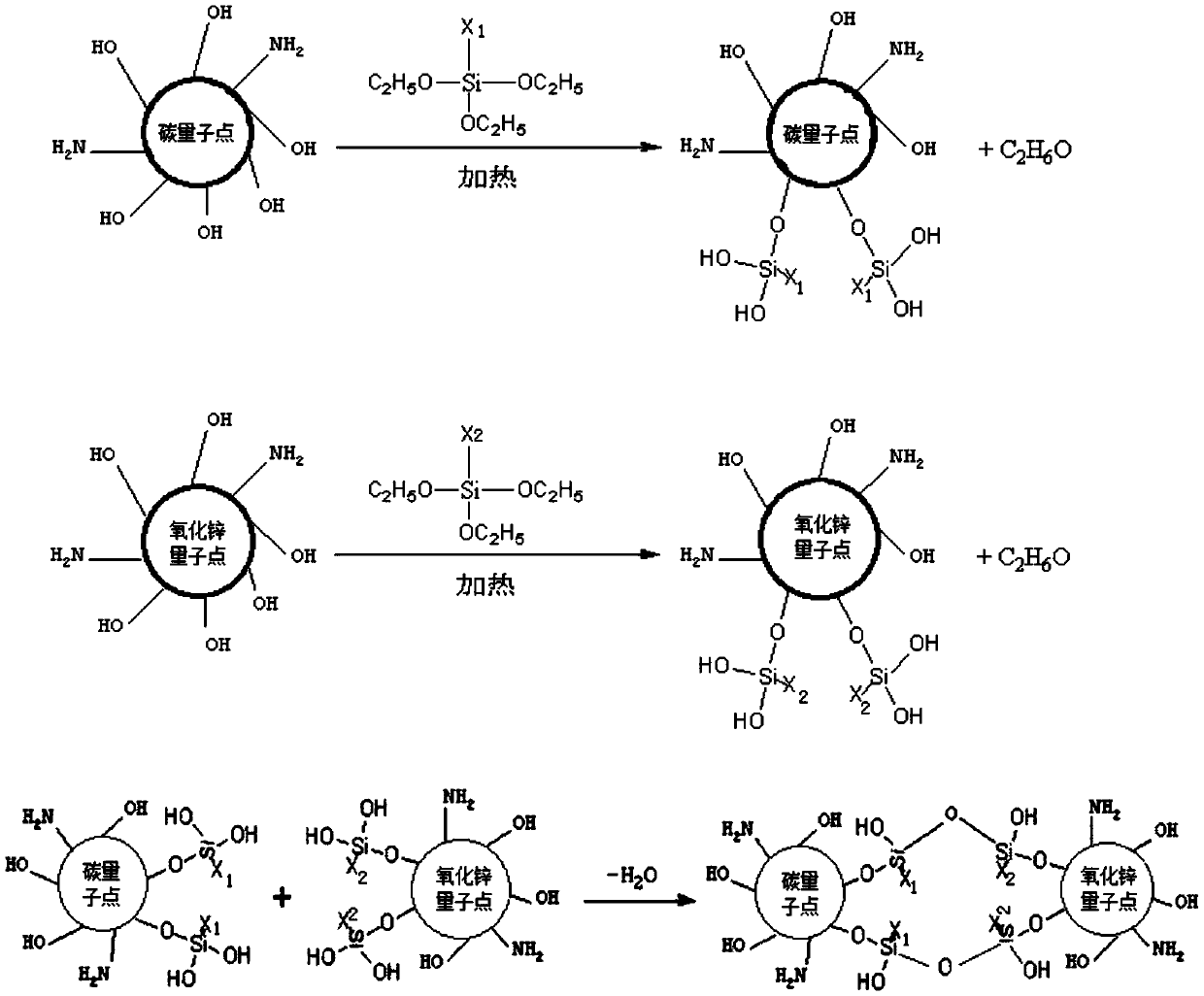

[0029] In the preparation method of the composite material provided by the embodiment of the present invention, the surface is bound with -O-(X 1 )Si(OH) 2 The carbon quantum dots and the surface are bound with -O-(X 2 )Si(OH) 2 The zinc oxide quantum dots are mixed and heated to obtain carbon quantum dots and zinc oxide quantum dots through -O-(X 1 )Si(OH)-O-(X 2)Si(OH)-O-composites. The prepara...

Embodiment 1

[0053] Taking vinyltriethoxysilane as a coupling agent as an example for a detailed introduction.

[0054] (1) 2g of ethylenediamine was added to 3g of citric acid aqueous solution, then the above solution was transferred to a reaction kettle, and heated to 70 degrees Celsius in an oven for 40 hours. Then let it cool down to room temperature naturally. The cooled solution was centrifuged at 2000 rpm, and the supernatant obtained was the original carbon quantum dot solution.

[0055] (2) Dilute 0.2 g of the carbon quantum dot solution prepared in the above process with deionized water for 10, add vinyltriethoxysilane to the carbon quantum dot solution, and heat at 60 degrees Celsius to obtain the first solution.

[0056](3) After mixing 2g of zinc acetate and 1.5g of ethanol, reflux at 80 degrees Celsius until the zinc salt is completely dissolved, then cool the solution at 5 degrees Celsius / minute, and quickly pour the sodium hydroxide solution into it and stir until the solu...

Embodiment 2

[0061] A detailed introduction is given using vinyl tris(β-methoxyethoxy)silane as coupling agent.

[0062] (1) 90g of aniline was added to 180g of oxalic acid aqueous solution, then the solution was transferred to a reaction kettle, and heated to 260 degrees Celsius in an oven for 2 hours. Then let it cool down to room temperature naturally. The cooled solution was centrifuged at 7000 rpm, and the supernatant obtained was the original carbon quantum dot solution.

[0063] (2) Get 50 g of the carbon quantum dot solution prepared in the above process and dilute 40 times with deionized water, add vinyl tris (β-methoxyethoxy) silane in the carbon quantum dot solution, and heat at 60 degrees Celsius to obtain the first solution.

[0064] (3) After mixing 85g of zinc chloride and 90g of polyethylene glycol, reflux at 80 degrees Celsius until the zinc salt is completely dissolved, then cool the solution at 10 degrees Celsius / min, and quickly pour the n-butyllithium solution into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com