Stannic oxide composite material as well as preparation method and application thereof

A technology of tin dioxide and composite materials, which is applied in the direction of secondary batteries, electrochemical generators, active material electrodes, etc., and can solve problems such as excessive capacity failure, volume expansion effect, and poor cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

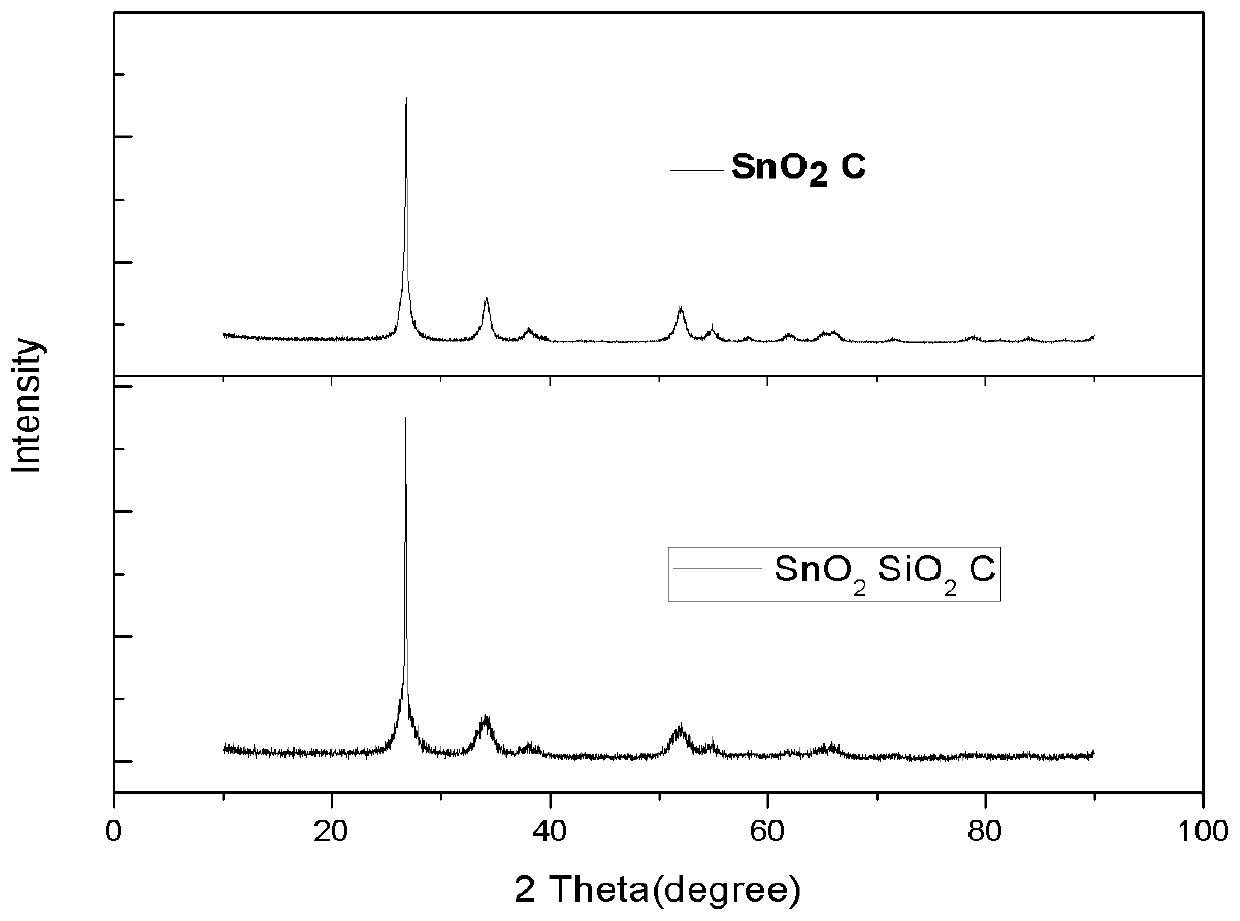

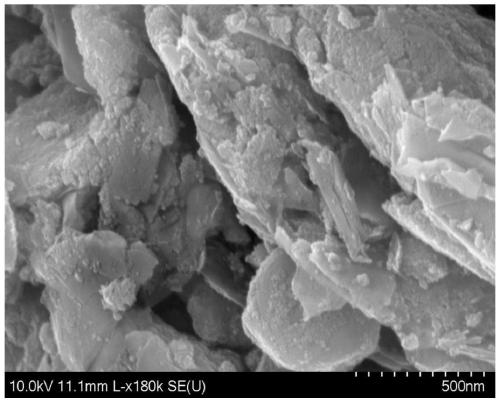

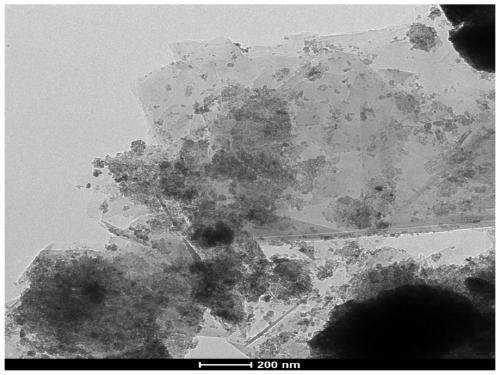

Image

Examples

Embodiment 1

[0037] The present embodiment carries out the preparation of tin dioxide composite material, comprises the following steps:

[0038] 1) Take by weighing 7.5g sodium stannate trihydrate and 20g urea, measure the mixed solution of 150ml deionized water and 150ml absolute ethanol, mix the above-mentioned sodium stannate trihydrate, urea, deionized water and absolute ethanol Pour the solution into a beaker and add a magnetic stirrer, put it on the magnetic stirrer and stir for 2 hours; pour the evenly stirred mixed solution into the inner tank of the hydrothermal kettle, put the inner tank into the hydrothermal kettle, and put the hydrothermal kettle into the dry In the box, set the temperature of the drying box to 200° C., and carry out the hydrothermal reaction for 18 hours.

[0039] 2) Clean the hydrothermal reaction product, specifically: take 5 to 6 test tubes, pour off excess water from the solution after the hydrothermal reaction, add deionized water to rinse the precipitat...

Embodiment 2

[0042]The present embodiment carries out the preparation of tin dioxide composite material, with embodiment 1, but step 1) takes by weighing 8g sodium stannate trihydrate, stirs 1h; Step 3) in the first ball mill, weighs 0.7g above-mentioned prepared Pour tin oxide and 0.15g of silicon oxide into a ball mill tank for the first ball milling, the mass ratio of material to beads is 1:35; step 3) weigh 0.15g of graphite for the second ball milling.

Embodiment 3

[0044] This embodiment carries out the preparation of tin dioxide composite material, with embodiment 1, but step 1) take by weighing 8g sodium stannate trihydrate and 24g urea, stir 1h; Step 3) in the first ball mill, weigh 0.7g above-mentioned preparation The obtained tin dioxide and 0.05g of silicon were poured into a ball mill jar, the mass ratio of material to beads was 1:25, and the first ball mill was carried out for 20 hours; step 3) 0.15g of graphite was weighed for the second ball mill for 10 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com