Method for preparing graphene by recovering graphite from waste lithium ion battery negative electrode material

A lithium-ion battery and negative electrode material technology, which is applied in the field of recycling graphite to prepare graphene, can solve problems such as danger and high requirements for instrument staff, and achieve the effects of high recovery rate, low cost and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

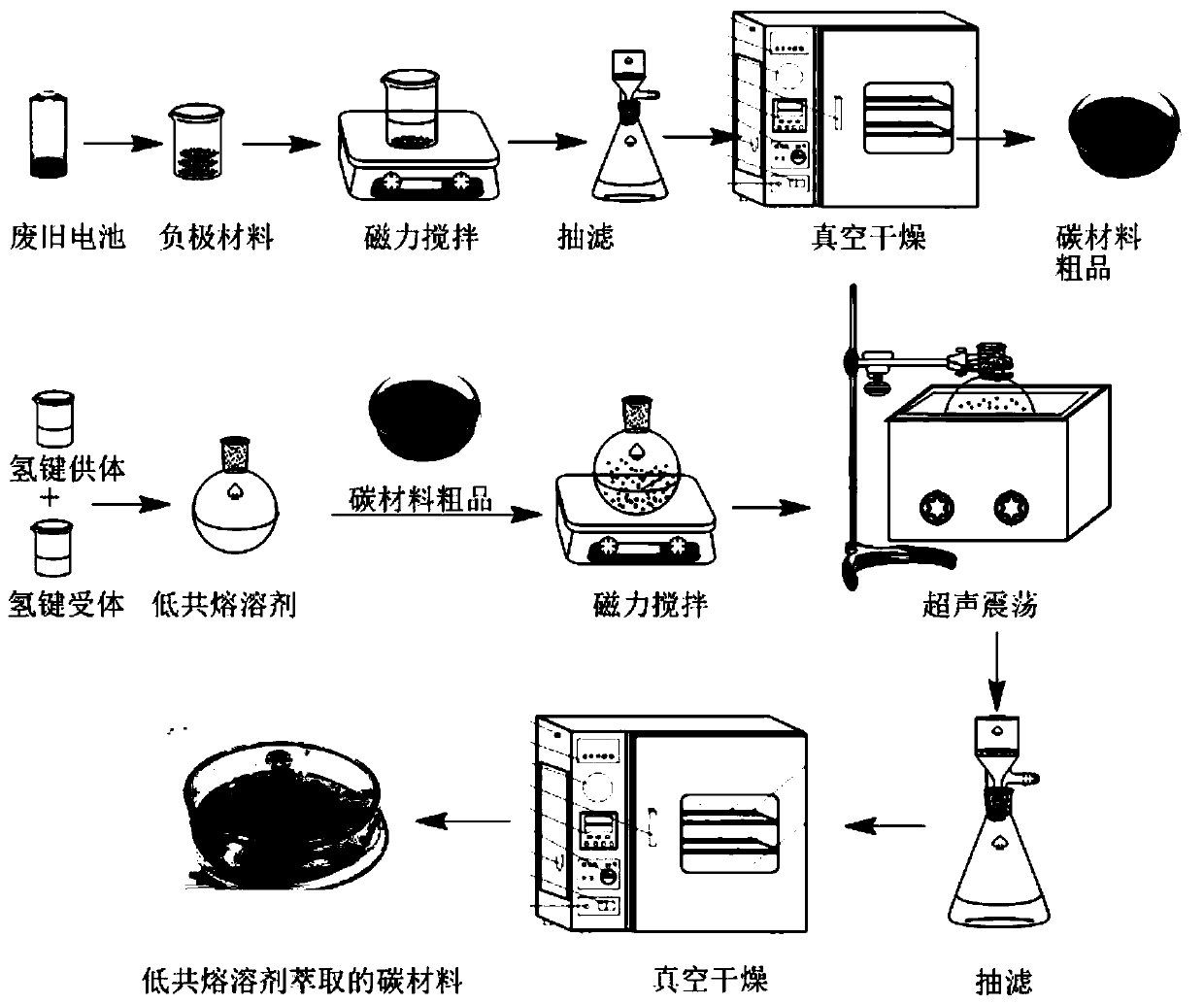

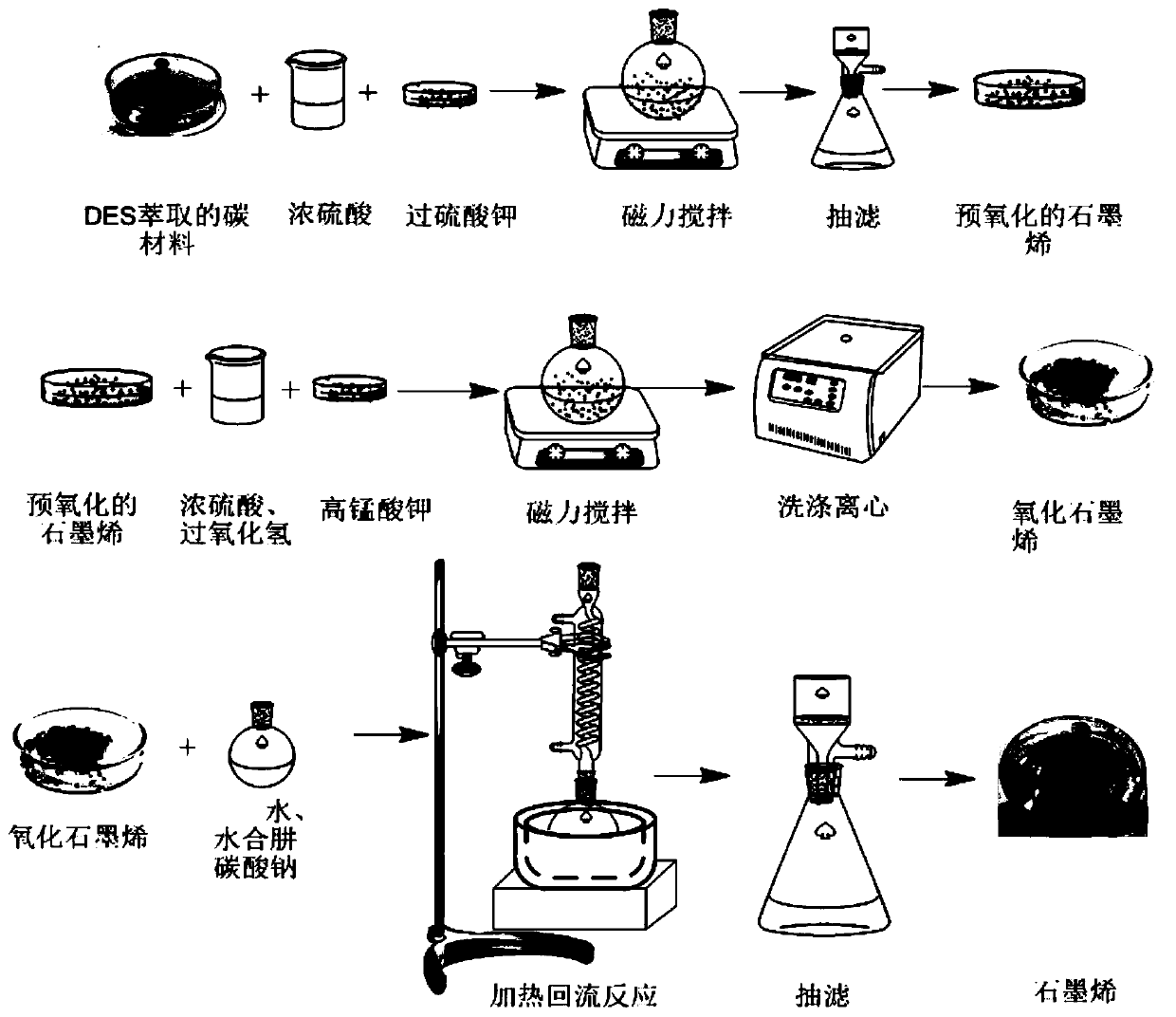

[0036] A method for preparing graphene from reclaiming graphite from waste lithium-ion battery negative electrode materials, the specific steps are:

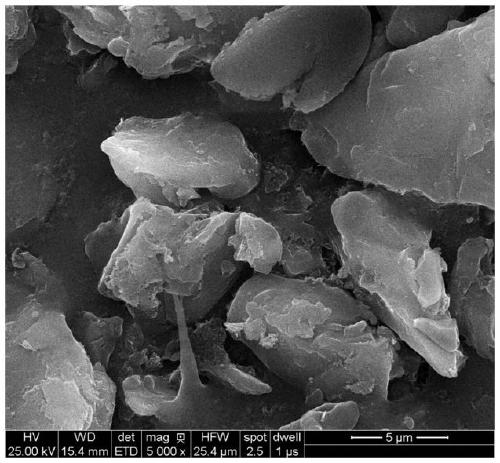

[0037] (1) After fully discharging the used lithium manganese oxide battery, peel off the casing, disassemble the battery, and take out the positive and negative electrodes and store them separately. Put the negative plate in the deionized water solution, after soaking for 3 hours, completely separate the copper foil from the graphite, use the Buchner funnel to filter the graphene-containing aqueous solution, and wash the filter residue with deionized water for 3 times. ℃ in a vacuum drying oven for 12 hours to obtain a crude negative electrode carbon material, the SEM image of which is image 3 shown.

[0038] (2) Using choline chloride as the hydrogen bond acceptor and glycerol as the hydrogen bond donor, the molar ratio is 1:2, the temperature is 60°C, and stirred at 1000r / min for 1h in a magnetic stirrer to prepare a low-ec...

Embodiment 2

[0045] A method for preparing graphene from reclaiming graphite from waste lithium-ion battery negative electrode materials, the specific steps are:

[0046] (1) After fully discharging the used lithium cobalt oxide battery, peel off the shell, disassemble the battery, and take out the positive and negative electrodes and store them separately. Put the negative plate in the deionized water solution, after soaking for 3 hours, completely separate the copper foil from the graphite, use the Buchner funnel to filter the graphene-containing aqueous solution, and wash the filter residue with deionized water for 3 times. °C in a vacuum oven for 12 hours to obtain a crude negative electrode carbon material.

[0047] (2) Using nicotinic acid as a hydrogen bond acceptor and urea as a hydrogen bond donor with a molar ratio of 1:3 and a temperature of 40°C, stir in a magnetic stirrer at 800r / min for 3h to prepare a deep eutectic solvent.

[0048] (3) Extract the crude negative electrode ...

Embodiment 3

[0052] A method for preparing graphene from reclaiming graphite from waste lithium-ion battery negative electrode materials, the specific steps are:

[0053] (1) After fully discharging the used lithium iron phosphate battery, peel off the casing, disassemble the battery, and take out the positive and negative electrodes and store them separately. Place the negative electrode sheet in deionized water solution, soak for 1 hour, completely separate the copper foil from the graphite, use a Buchner funnel to filter the graphene-containing aqueous solution, and wash the filter residue with deionized water for 3 times. °C in a vacuum drying oven for 10 h to obtain a crude negative electrode carbon material.

[0054] (2) Use acetylcholine chloride as the hydrogen bond acceptor, xylitol as the hydrogen bond donor, the molar ratio is 1:1, the temperature is 30°C, stir at 600r / min for 12h in a magnetic stirrer to prepare a deep eutectic melt solvent.

[0055] (3) Extract the crude neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com