Carboxyl-containing perylene bisimide/oxygen-doped carbon nitride nanosheet heterojunction photocatalyst as well as preparation method and application thereof

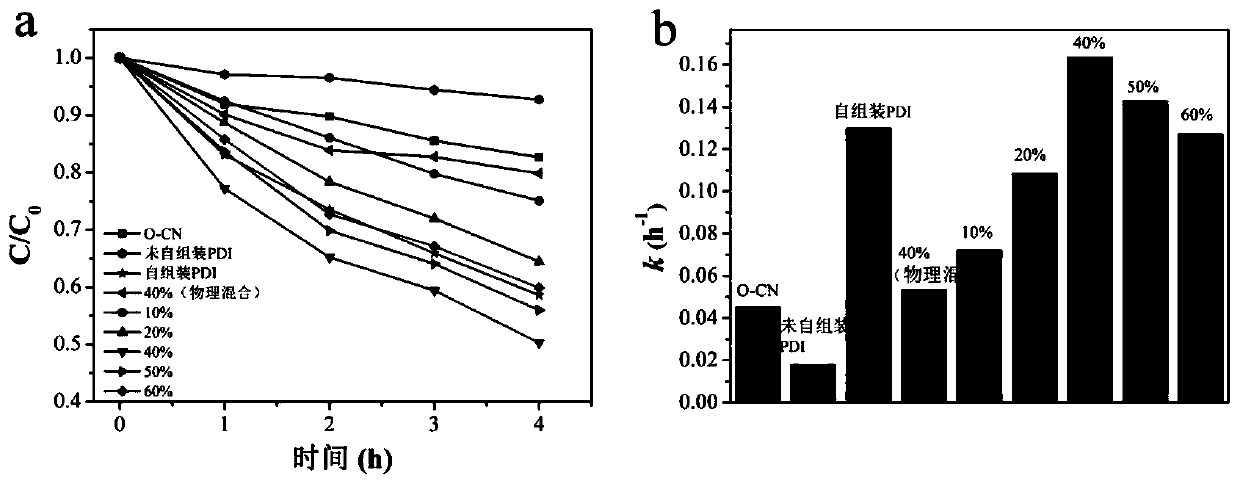

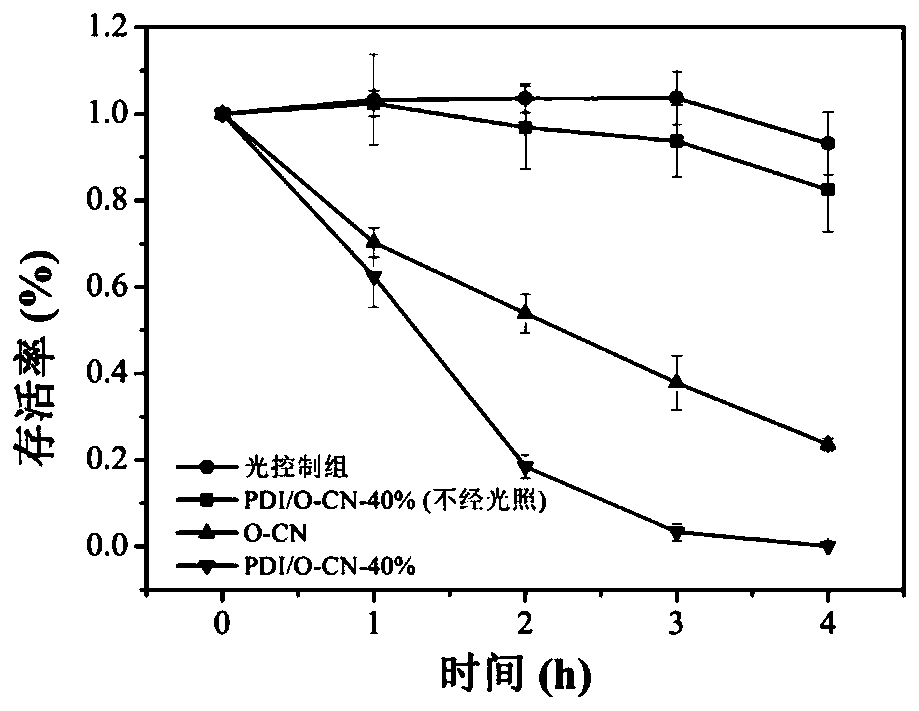

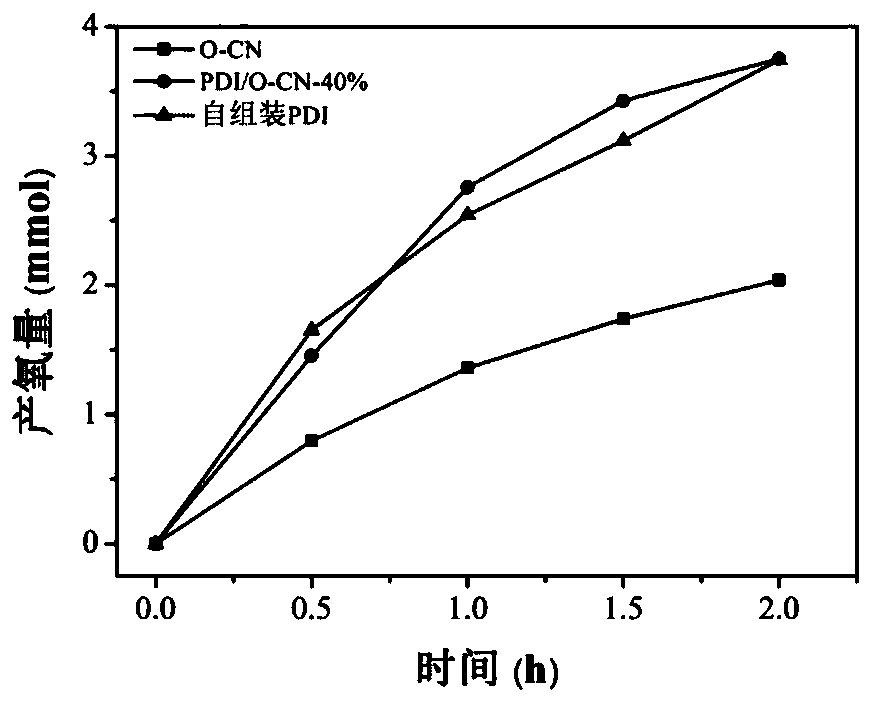

A perylene imide and photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of high recombination probability of photogenerated electron-hole pairs, affect the application prospect of photocatalysis, and the catalytic activity is easily affected by pH, so as to achieve rapid transfer Expansion, excellent degradation of pollutants, and improvement of migration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A carboxyl peryleneimide / oxygen-doped carbon nitride nanosheet heterojunction photocatalyst, the preparation method of the photocatalyst comprises the following steps:

[0040] First, put 3-amino-1,2,4-triazole in a crucible, put it into a muffle furnace, heat up to 550°C at a rate of 2°C / min and calcinate for 4 hours, and grind the product to obtain a brick-red block carbon nitride; grind block carbon nitride, place it in a crucible, put it into a muffle furnace, heat up to 500 °C at a rate of 5 °C / min for secondary calcination for 2 hours, and grind the product to obtain carbon nitride nano sheet; disperse 0.9g carbon nitride nanosheets in 100mL 30vol% H 2 o 2 Ultrasonic (560W, 40kHz) in aqueous solution for 30 minutes, then transfer the dispersion to a hydrothermal kettle, heat at 120°C for 6 hours, collect the precipitate by centrifugation, wash the precipitate with water several times, dry it and grind it into powder to obtain a bright yellow powder The product i...

Embodiment 2

[0042] A carboxyl peryleneimide / oxygen-doped carbon nitride nanosheet heterojunction photocatalyst, the preparation method of the photocatalyst comprises the following steps:

[0043] First, put 3-amino-1,2,4-triazole in a crucible, put it into a muffle furnace, heat up to 450°C at a rate of 1°C / min and calcinate for 1 hour, and grind the product to obtain a brick-red block carbon nitride; grind block carbon nitride, place it in a crucible, put it into a muffle furnace, heat up to 450 °C at a rate of 1 °C / min for secondary calcination for 1 h, and grind the product to obtain carbon nitride nano sheet; disperse 1g carbon nitride nanosheets in 30mL 0.1vol% H 2 o 2 Ultrasonic (200W, 10kHz) in aqueous solution for 5 minutes, then transfer the dispersion to a hydrothermal kettle, heat at 80°C for 2 hours, collect the precipitate by centrifugation, wash the precipitate with water several times, dry it and grind it into powder to obtain a bright yellow powder The product is oxygen-...

Embodiment 3

[0045] A kind of heterojunction photocatalyst containing carboxyl peryleneimide / oxygen-doped carbon nitride nanosheet, the preparation method of said photocatalyst comprises the following steps:

[0046] First, put 3-amino-1,2,4-triazole in a crucible, put it into a muffle furnace, heat up to 600°C for 8 hours at a rate of 12°C / min, and grind the product to obtain a brick-red block carbon nitride; grind block carbon nitride, place it in a crucible, put it into a muffle furnace, heat up to 600 °C at a rate of 12 °C / min for secondary calcination for 8 hours, and grind the product to obtain carbon nitride nano sheet; disperse 1g carbon nitride nanosheets in 150mL 40vol% H 2 o 2 Ultrasonic (800W, 50kHz) in aqueous solution for 60min, then transfer the dispersion to a hydrothermal kettle, heat at 150°C for 10h, collect the precipitate by centrifugation, wash the precipitate with water several times, dry it and grind it into powder to obtain a bright yellow powder The product is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com