BOPP synthetic paper primer coating and preparation method thereof

A technology for synthetic paper and coatings, applied in coatings, primers, etc., can solve problems such as low production efficiency, non-conformity with environmental protection development concepts, and increased production costs, so as to reduce energy consumption, facilitate development and promotion, and increase production speed Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

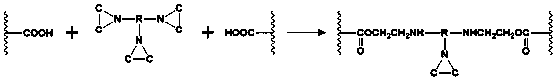

Method used

Image

Examples

Embodiment 1

[0029] Take 20% pure acrylic emulsion, 1.2% ammonium zirconium carbonate, 0.6% aziridine, 1.4% polyether defoamer, and 1% fatty acid ester. At room temperature, add pure acrylic emulsion, turn on the stirring, the speed is 400rpm, add a certain amount of water, stir for 10min, then add aziridine, the stirring speed is 200rpm, stir for 40min, then add ammonium zirconium carbonate, the speed is 250rpm, stir for 10min, Then add fatty acid ester, stir at 300rpm, stir for 15min, finally add polyether defoamer, continue to stir at 200rpm for 40min, until the mixture is evenly mixed, and then adjust the solid content of the required primer by adding water. The solid content of the paint is 14.5%, and the viscosity of the paint (coating 4 cups) is 11.0''. The coating is then coated on synthetic paper with a coating weight of 4.0g / m 2 Then put it in a 90°C oven and dry it for 1.5min to make it completely cured. The measured surface tension value is 46, and the surface fastness is OK ...

Embodiment 2

[0031] Take 25% of silicon-acrylic emulsion, 1.5% of ammonium zirconium carbonate, 0.8% of aziridine, 1.2% of polyether defoamer, 1.2% of fatty acid ester, add silicon-acrylic emulsion at room temperature, turn on the stirring, rotate at 300rpm, add A certain amount of water, stirred for 20min, then added aziridine, stirred at 250rpm, stirred for 45min, then added ammonium zirconium carbonate, stirred at 300rpm, stirred for 20min, then added fatty acid ester, stirred at 400rpm, stirred for 20min, then added polyether For defoaming agent, continue to stir at a stirring speed of 300rpm for 45min until the stirring and mixing are uniform, and then adjust the solid content of the required primer by adding water. The solid content of the paint is 16.0%, and the viscosity of the paint (4 cups of paint): 11.3''. Then the coating is coated on the synthetic paper, the coating amount is about 4.3g / m2. Then put it in an oven at 90°C and dry it for 1.2 minutes to make it completely cured...

Embodiment 3

[0033] Take 30% of styrene-acrylic emulsion, 1.8% of ammonium zirconium carbonate, 1.1% of aziridine, 0.9% of polyether defoamer, 1.5% of fatty acid ester, add silicon-acrylic emulsion at room temperature, turn on the stirring, rotate at 500rpm, add A certain amount of water, stirred for 15min, then added aziridine, stirred at 350rpm, stirred for 50min, then added ammonium zirconium carbonate, stirred at 400rpm, stirred for 25min, then added fatty acid ester, stirred at 350rpm, stirred for 25min, then added polyether For defoaming agent, continue to stir at a stirring speed of 250rpm for 50min until the stirring is uniform, and then adjust the solid content of the required primer by adding water. The solid content of the paint is 17.5%, and the viscosity of the paint (4 cups of paint): 11.5''. Coat the prepared primer coating on the synthetic paper, the coating amount is about 4.6g / m2. Then place it in a 90°C oven and dry it for 1 min, when the coating is completely cured. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com