Preparation method of environment-friendly water-saving fracturing fluid

A fracturing fluid and water-saving technology, applied in the field of fracturing, can solve the problems of wasting road transportation and sewage treatment costs, limited reinjection water, and failure to carry sand, so as to achieve good sand carrying performance and equipment No corrosion, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

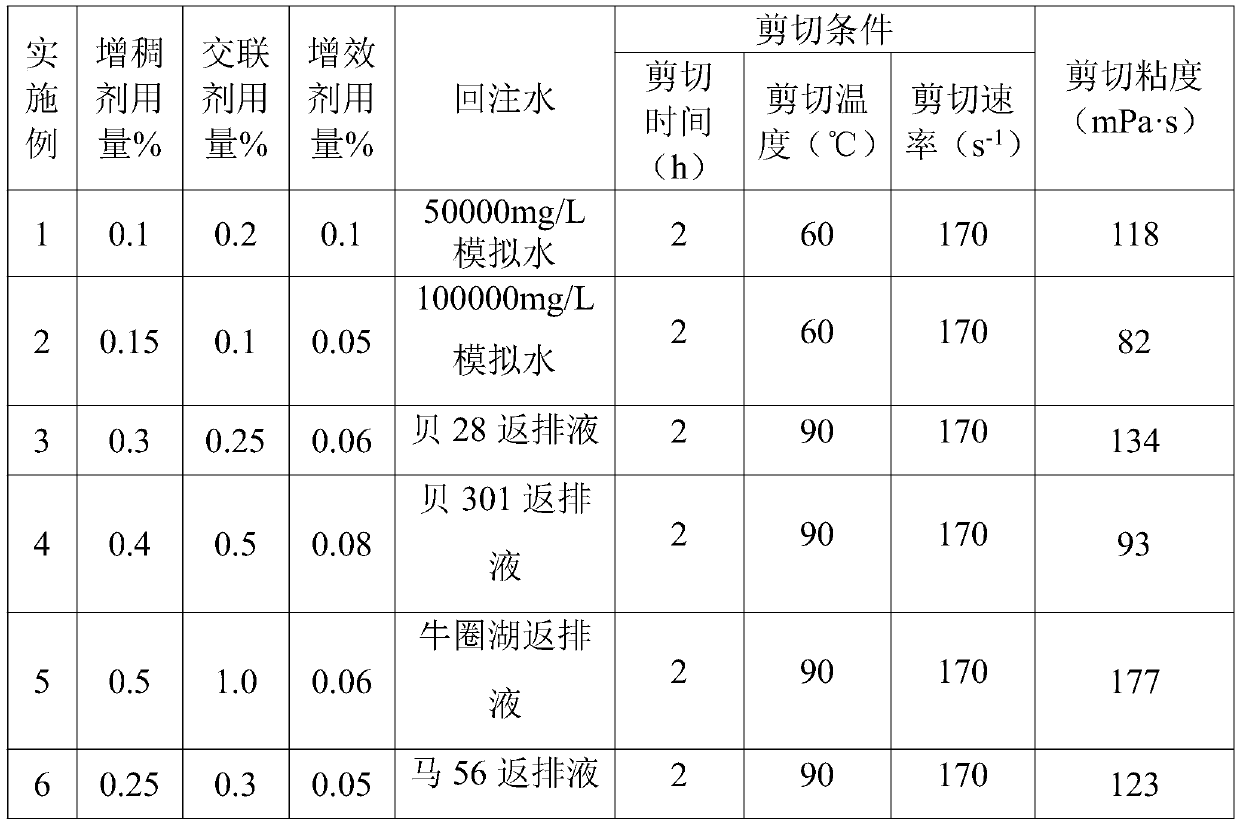

Embodiment 1

[0031] This embodiment provides an environmentally friendly and water-saving fracturing fluid, which is composed of acrylamide, hydroxypropyl-β-cyclodextrin, 2-acrylamide-2-methyl Propanesulfonic acid and N-alkylmaleimide multi-polymer copolymer 0.1%, crosslinking agent 0.2%, synergist 0.1%, gel breaker ammonium persulfate 2.0%, balance 50000mg / L ore The degree of crystallization simulates water. Wherein, the composition of the crosslinking agent according to weight percentage is: 10% alkanolamide, 10% betaine, 15% sodium alkylbenzenesulfonate, 20% glycerol, and the balance is water, wherein the alkanolamide is 1:1.5 type coconut oil diethanolamide, betaine is BS18 betaine, sodium alkylbenzene sulfonate is sodium C12 alkylbenzene sulfonate. The composition of the synergist in parts by weight is: 15 parts of cetyltrimethylammonium bromide, 7 parts of fatty acid glyceride, 5 parts of iminodisuccinic acid sodium salt, and 40 parts of methanol. The preparation method of the thic...

Embodiment 2

[0039] This embodiment provides an environmentally friendly and water-saving fracturing fluid, which is composed of acrylamide, hydroxypropyl-β-cyclodextrin, 2-acrylamide-2-methyl Propanesulfonic acid, N-alkylmaleimide multi-component copolymer 0.15%, crosslinking agent 0.1%, synergist 0.05%, gel breaker ammonium persulfate 0.5%, the balance is salinity 100000mg / L salinity simulates water. Wherein, the composition of the crosslinking agent in parts by weight is: 15% alkanolamide, 5% betaine, 10% sodium alkylbenzene sulfonate, 25% mannitol, and the balance is water, wherein the alkanolamide is 1 : Type 1.5 coconut oil diethanolamide, betaine is BS18 betaine, sodium alkylbenzene sulfonate is sodium C18 alkylbenzene sulfonate. The composition of the synergist in parts by weight is: 17 parts of benzalkonium chloride, 5 parts of alkylphenol polyoxyethylene ether, 10 parts of iminodisuccinic acid sodium salt, and 60 parts of methanol. The preparation method of this multi-componen...

Embodiment 3

[0042]This embodiment provides an environmentally friendly and water-saving fracturing fluid, which is composed of acrylamide, hydroxypropyl-β-cyclodextrin, 2-acrylamide-2-methyl Propanesulfonic acid, N-alkylmaleimide multi-polymer copolymer 0.3%, cross-linking agent 0.25%, synergist 0.06%, drainage aid 0.2%, iron ion stabilizer 0.2%, alginate 0.1% , and the balance is Bei 28 flowback fluid. Wherein, the composition of the crosslinking agent in parts by weight is: 12% alkanolamide, 8% betaine, 12% sodium alkylbenzenesulfonate, 30% mannitol, and the balance is water, wherein the alkanolamide is 1 : Type 1.5 coconut oil diethanolamide, betaine is BS18 betaine, sodium alkylbenzene sulfonate is sodium C15 alkylbenzene sulfonate. The composition of the synergist in parts by weight is: 20 parts of octadecyl dimethyl benzyl ammonium chloride, 6 parts of alkyl glucoside, 8 parts of iminodisuccinic acid sodium salt, and 50 parts of methanol. The preparation method of this multi-compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com