Graphene electric heating painting

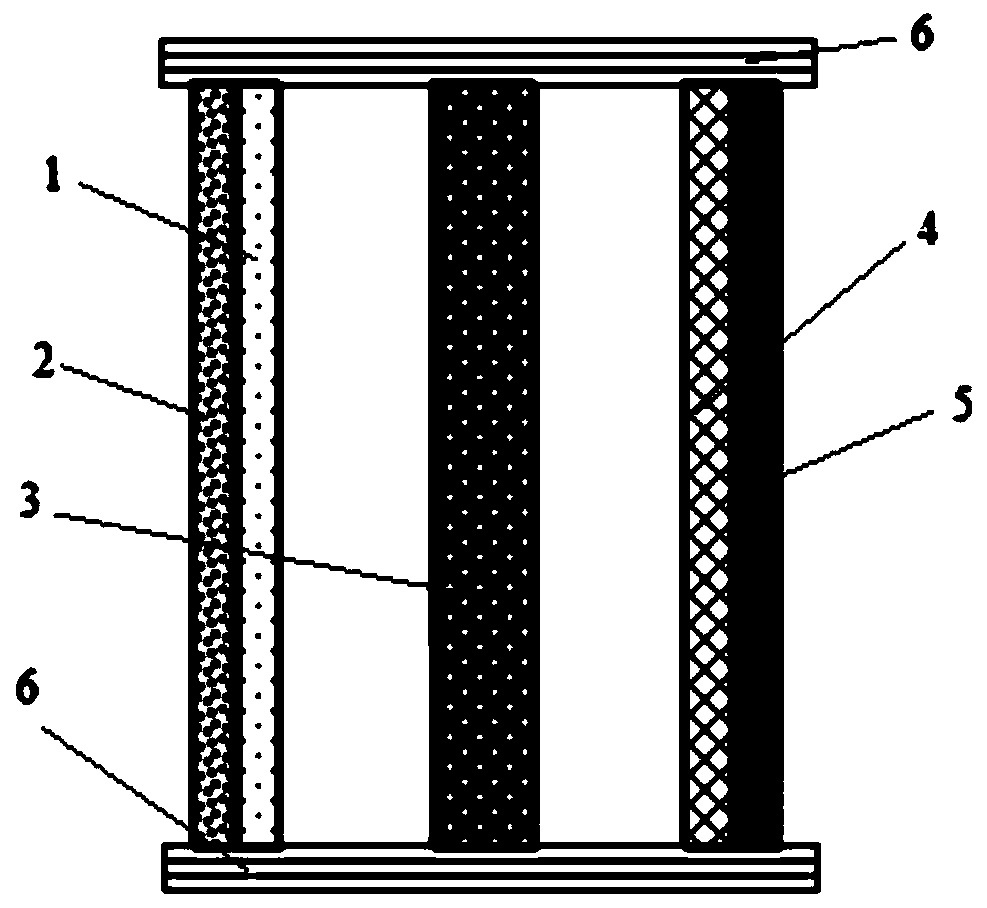

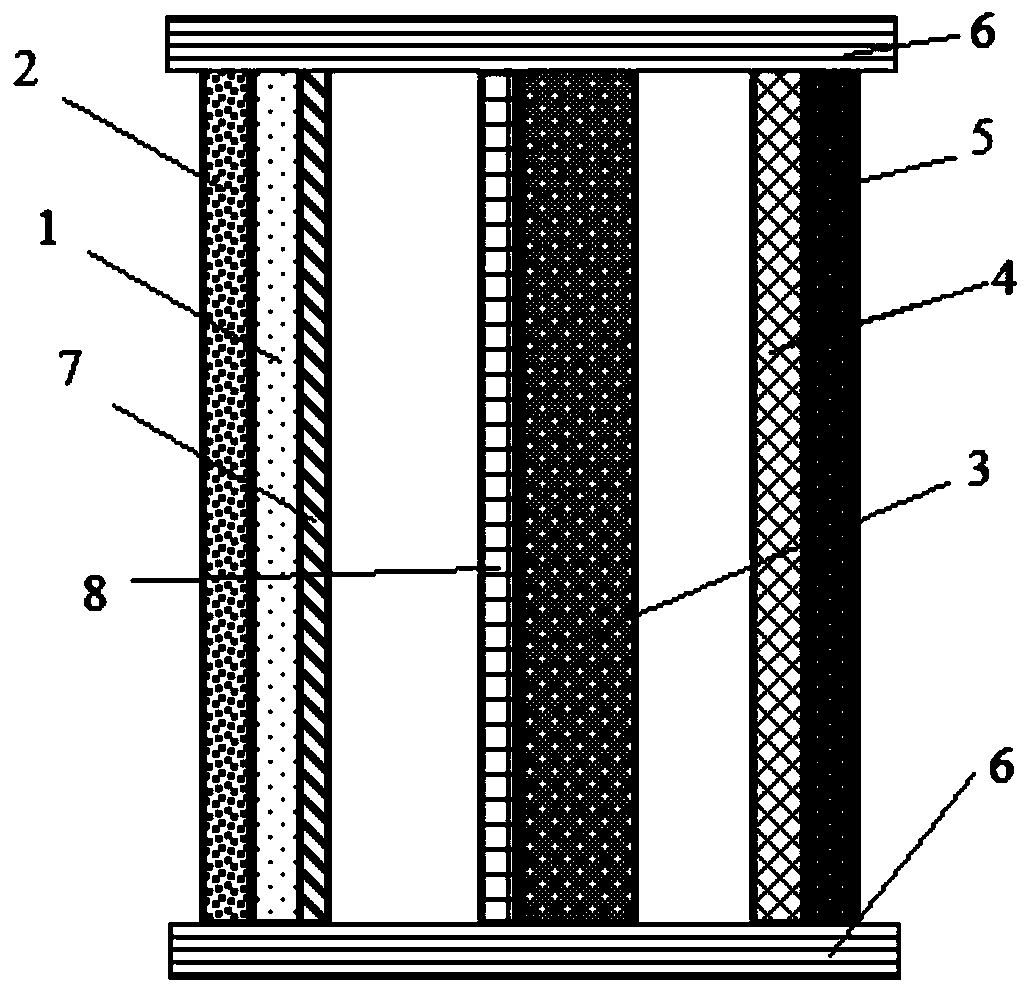

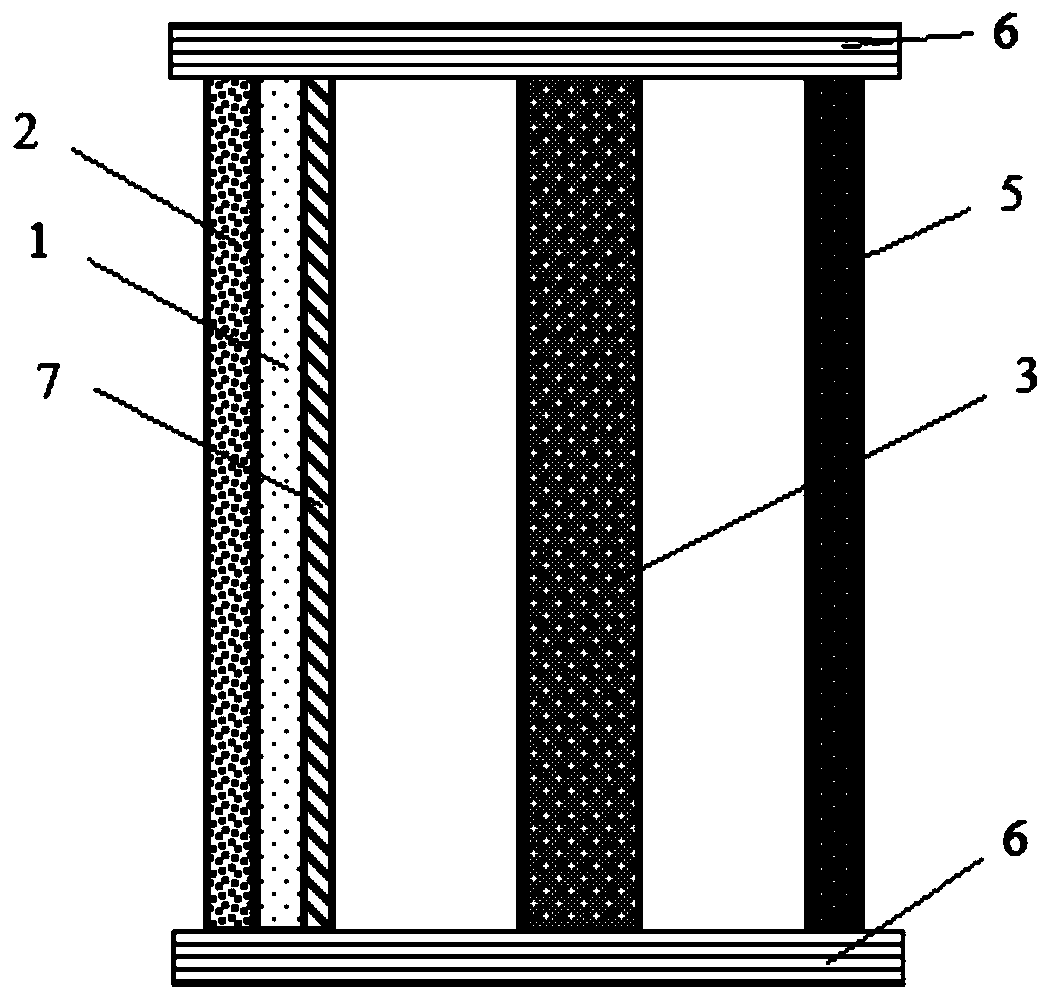

An electrothermal painting and graphene technology, which is applied in the structural field of far-infrared electrothermal heating paintings, can solve the problems of low far-infrared radiation efficiency and slow heating speed on the front of the decorative layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] 1. Preparation of graphene heating element

[0128] 1-1) Print the graphene slurry on the surface of the glass fiber board with electrical insulation properties by screen printing, print the graphene layer on the surface, and bake it at 150°C for 60 minutes to form a thickness of 50 μm (usually 10-200μm) graphene dry film thin layer;

[0129] In addition to screen printing, others such as coating are suitable for the present invention.

[0130] 1-2) Print the silver paste electrode on the glass fiber board, and overlap the silver paste electrode and the graphene dry film layer to form a good electrical connection. After printing the silver paste, after baking at 150 ° C for 60 minutes, a dry film, and the thickness of the film is 25 μm (usually 20-30 μm), made of silver paste electrode-graphene heating layer-glass fiber board;

[0131] 1-3) Apply a layer of epoxy resin (adhesive) on the surface of the second glass fiber board, and press it with the silver paste electr...

Embodiment 2

[0160] 1. Preparation of graphene heating element

[0161] Except adopting the mode of coating, coating graphene slurry on mica substrate, making graphene heating element, except forming heating element layer, all the other are identical with embodiment 1;

[0162] 2. Preparation of infrared enhancement layer

[0163] Same as Example 1.

[0164] 3. Preparation of infrared absorbing layer

[0165] Same as Example 1.

[0166] 4. Preparation of decorative painting protective layer

[0167] Same as Example 1.

[0168] 5. Preparation of infrared reflective layer

[0169] Except for using composite aluminum foil reflective film (using soft aluminum foil, heat-resistant PE adhesive, PET and glass fiber composite processing), the rest is the same as that of embodiment 1.

[0170] 6. Assembly

[0171] Same as Example 1.

Embodiment 3

[0173] 1. Preparation of graphene heating element

[0174] Same as Example 1.

[0175] 2. Preparation of infrared enhancement layer

[0176] 2-1) Prepare reinforcement layer slurry

[0177] Mix infrared enhancement raw material silicon oxide powder, graphite powder and adhesive water-based epoxy resin, stir and disperse evenly, and prepare a reinforcement layer slurry with a viscosity of 2500cps (usually 1000-10000cps), in which the infrared enhancement raw material and adhesive The weight ratio of the agent is 20:80 (usually 10-30:70-90), the weight ratio of silicon oxide and graphite is 1:1 (usually 1:(0.5-1.5)), and The particle size of silicon oxide powder and graphite powder is 0.1-3 μm, preferably 0.1-0.5 μm.

[0178] 2-2) Coating treatment

[0179] Except that the infrared enhancement layer slurry is silicon oxide, graphite and water-based epoxy resin, the rest is the same as step 2-2) of Example 1.

[0180] 3. Preparation of infrared absorbing layer

[0181] Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com