Controlled drug-release magnesium or magnesium alloy bionic bone and preparation method thereof

A magnesium alloy, bionic bone technology, applied in the field of biomedical materials, can solve the problems of affecting the performance, easy formation of oxides or inclusions, complex preparation process, etc., to increase the success rate, improve the quality of life, and alleviate the effects of degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing magnesium or magnesium alloy bionic bone with controlled drug release, comprising the following steps:

[0034] According to the predetermined bone structure parameters, pulse laser processing is performed on magnesium or magnesium alloy to obtain porous magnesium or magnesium alloy;

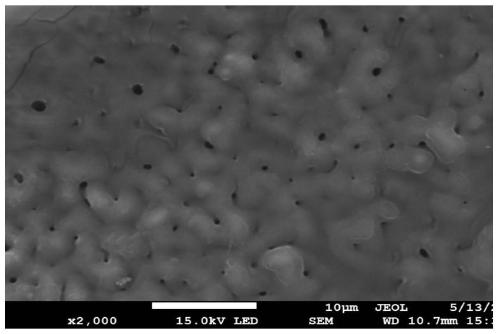

[0035] performing micro-arc oxidation treatment and alkali treatment on the porous magnesium or magnesium alloy in sequence to obtain modified porous magnesium or magnesium alloy;

[0036] Soak the modified porous magnesium or magnesium alloy in the Chinese medicine slow-release solution, take it out and dry it to obtain the controlled drug release magnesium or magnesium alloy bionic bone;

[0037] The traditional Chinese medicine sustained-release liquid includes naringin, polylactic acid-glycolic acid copolymer and an organic solvent; the organic solvent includes methylene chloride, chloroform, petroleum ether or ethyl acetate.

[0038] In ...

Embodiment 1

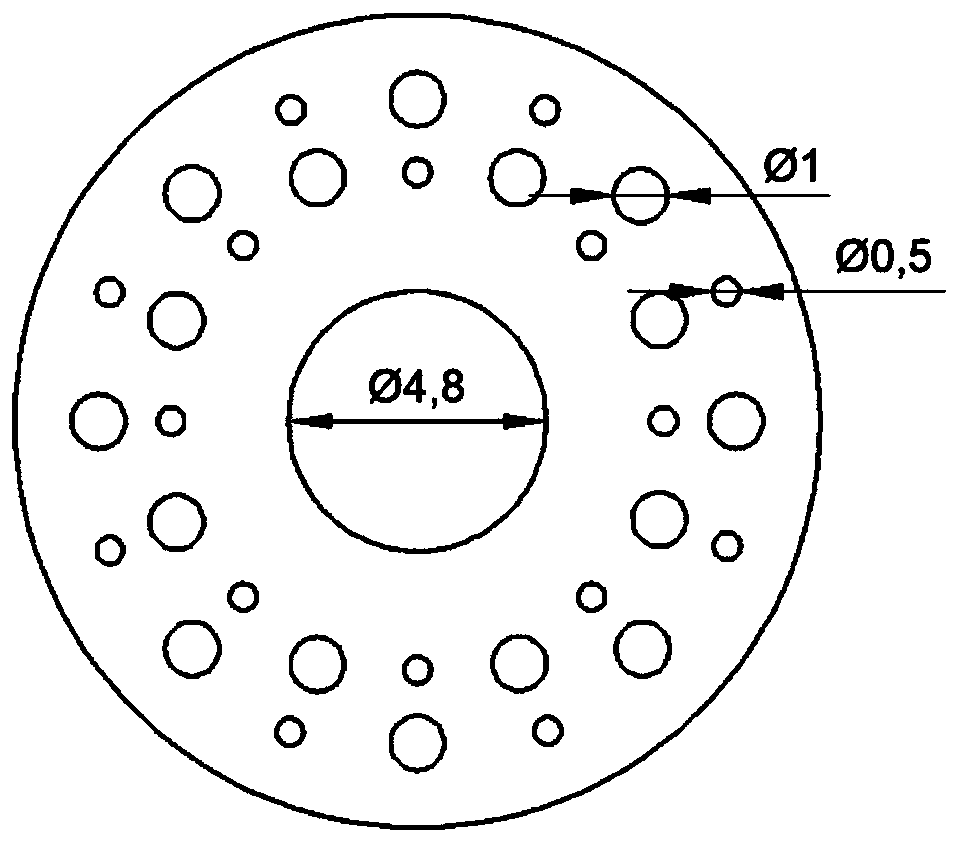

[0068] Design the pore size data of porous magnesium or magnesium alloy according to the structural parameters of the lower jaw of the rabbit (the porosity is 70%, and the pore size is 500 μm and 1000 μm respectively, such as figure 1 As shown), according to the finite element software, the geometric model and processing track of porous magnesium or magnesium alloy are established, and pulse laser processing is performed to obtain porous magnesium or magnesium alloy; wherein, the working parameters of the pulse laser processing include: a wavelength of 1064nm solid laser, laser spot The output energy is 10J, the output power is 60W, the output voltage is 800V, the pulse width is 1ms, the frequency is 10Hz, and the water temperature is 25°C.

[0069] Use water sandpaper to polish the porous magnesium or magnesium alloy until the surface is smooth, soak in ethanol for 2min, rinse with distilled water, place in 8g / mL NaHCO 3 In the solution for 10s, rinse with tap water, rinse ...

Embodiment 2

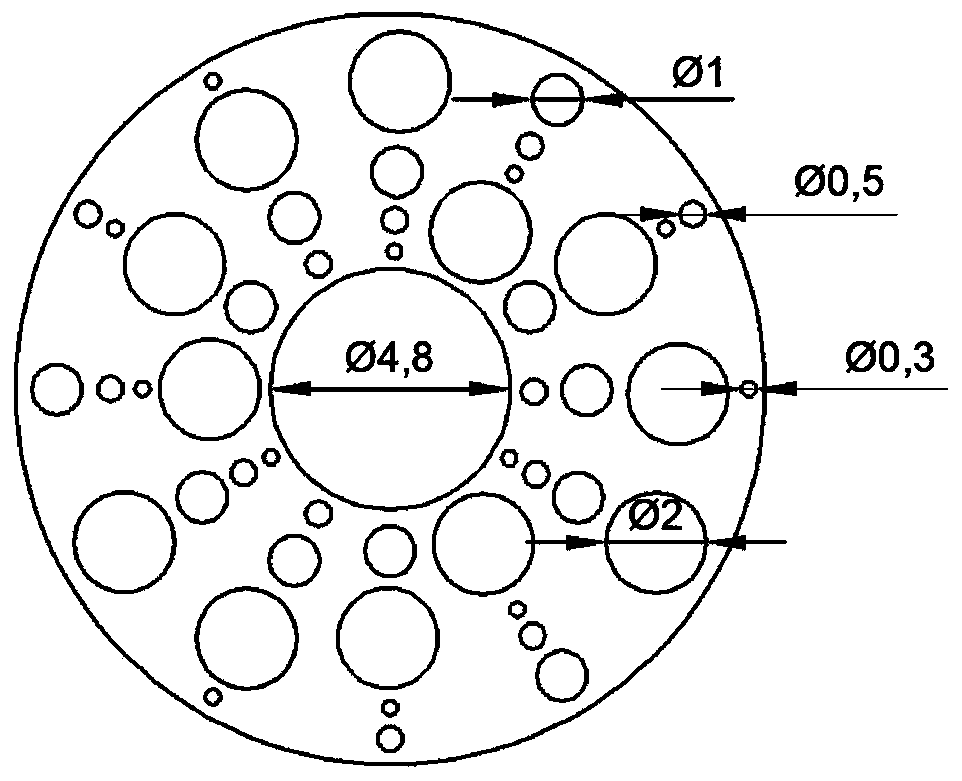

[0073] Prepare controlled drug release magnesium or magnesium alloy biomimetic bone according to the method of Example 1. The difference from Example 1 is that the pore diameter data of porous magnesium or magnesium alloy is: the porosity is 65%, and the pore diameters are 300 μm, 500 μm and 300 μm respectively. 1000μm, such as figure 2 shown;

[0074] The working parameters of pulsed laser processing include: solid-state laser with a wavelength of 1064nm, laser spot The output energy is 300μm, the output energy is 7J, the output power is 55W, the output voltage is 600V, the pulse width is 1.5ms, the frequency is 10Hz, and the water temperature is 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com