PVC aluminum foil plate with flame-retardant function and processing technology thereof

A processing technology, the technology of aluminum foil board, applied in the field of PVC aluminum foil board, can solve the problems of high production cost, large warping of PVC board, aluminum foil falling off, etc., and achieve the effect of small warpage, tight compounding and improved flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

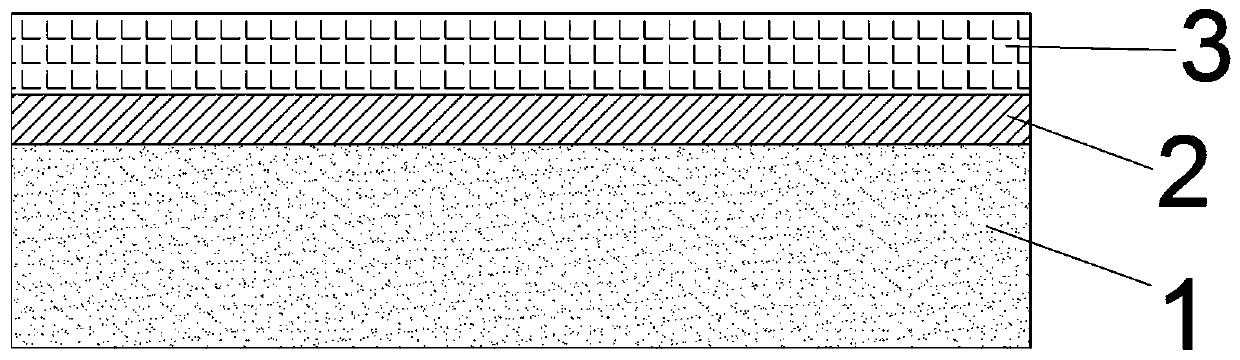

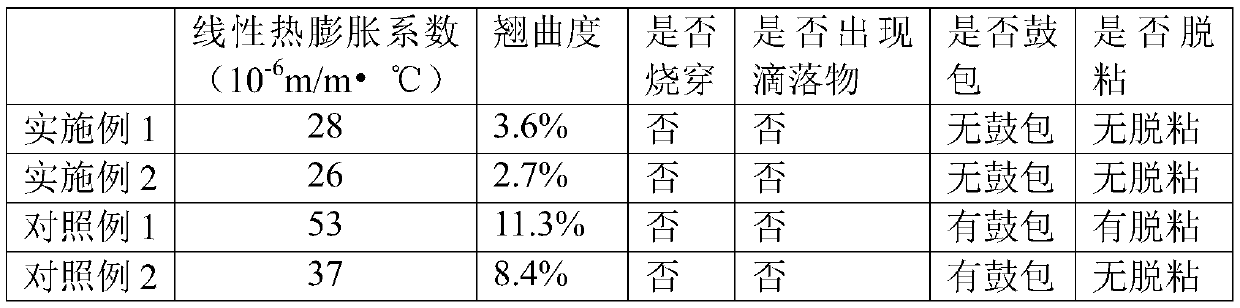

[0026] Such as figure 1 As shown, the PVC aluminum foil plate with flame-retardant function of the present invention includes a PVC substrate 1, and an aluminum foil 3 is bonded to the surface of one side of the PVC substrate 1, and the linear thermal expansion coefficient of the aluminum foil 3 is 23×10 -6 m / m·°C, the aluminum foil 3 is bonded on the PVC substrate 1 through the hot melt adhesive 2, and the hot melt adhesive 2 is polyester hot melt adhesive. In order to enhance the bonding strength between the aluminum foil 3 and the PVC substrate 1 , the PVC substrate 1 is also embossed with embossed patterns.

[0027] The internal lubricant that the present invention uses is modified butyl stearate, and the modification method of modified butyl stearate is: natural kapok fiber is under nitrogen atmosphere, 200 ℃ of carbonization 6 hours, obtain carbonized kapok fiber, then Dissolve 30 parts of butyl stearate in 200 parts of ethanol, then add 12 parts of carbonized kapok fib...

Embodiment 2

[0031] The difference with Example 1 is that the weight ratio of PVC sheet material, calcium zinc stabilizer, reinforcing agent mbs resin, toughening agent chlorinated polyethylene, external lubricant polyethylene wax, internal lubricant and flame retardant magnesium oxide is 120:5.3:1.7:2.3:2.6:3.4:8.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com