A drug-loadable microsphere and its preparation method

A technology of drug-loaded microspheres and microparticles, which can be used in the preparation of microspheres, pharmaceutical formulations, and microcapsule preparations. It can solve the problems of poor controlled release ability of the microsphere skeleton, reduced encapsulation efficiency, and inapplicability of temperature-sensitive protein polypeptide microspheres. etc. to achieve good biocompatibility, good adhesion and delivery, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

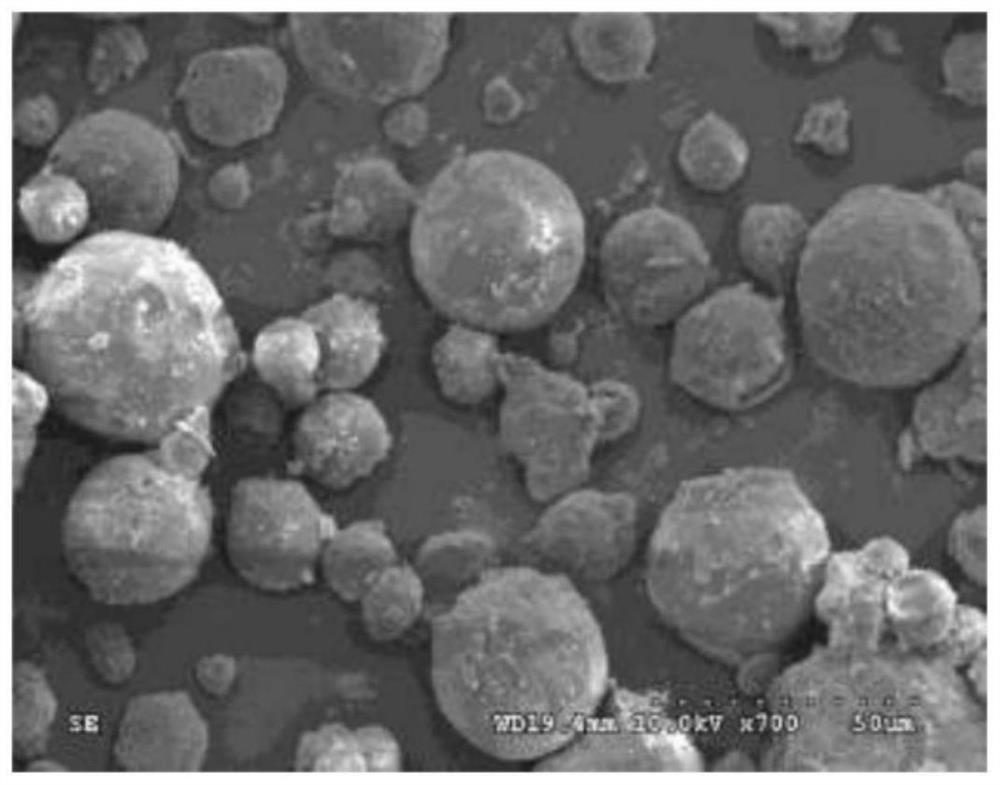

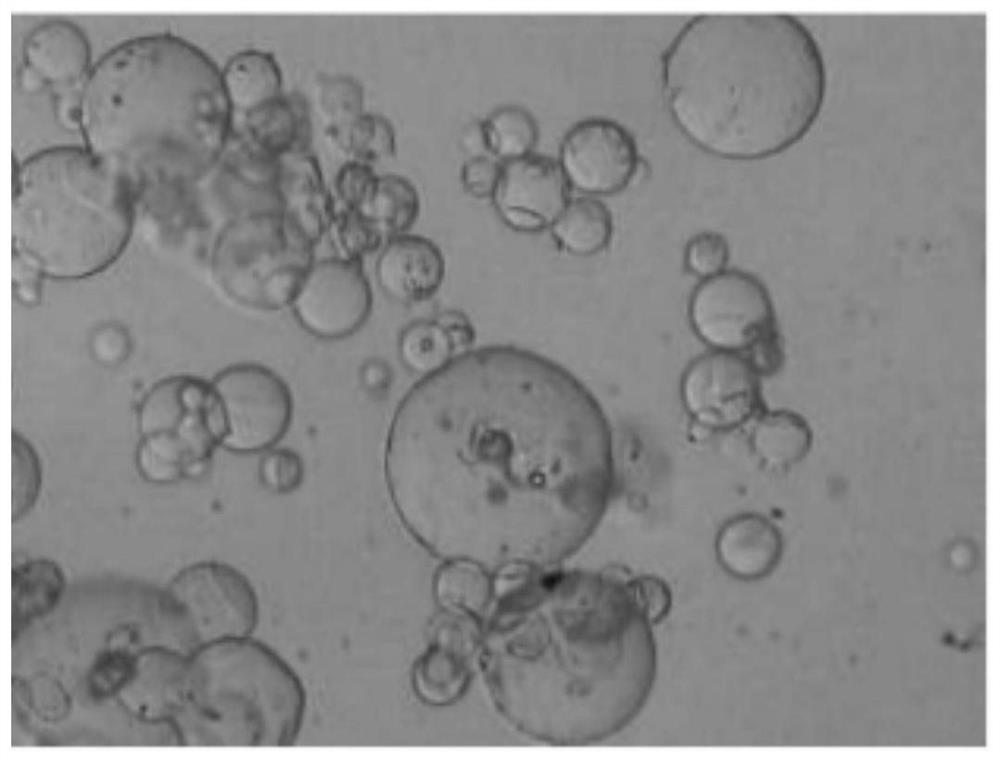

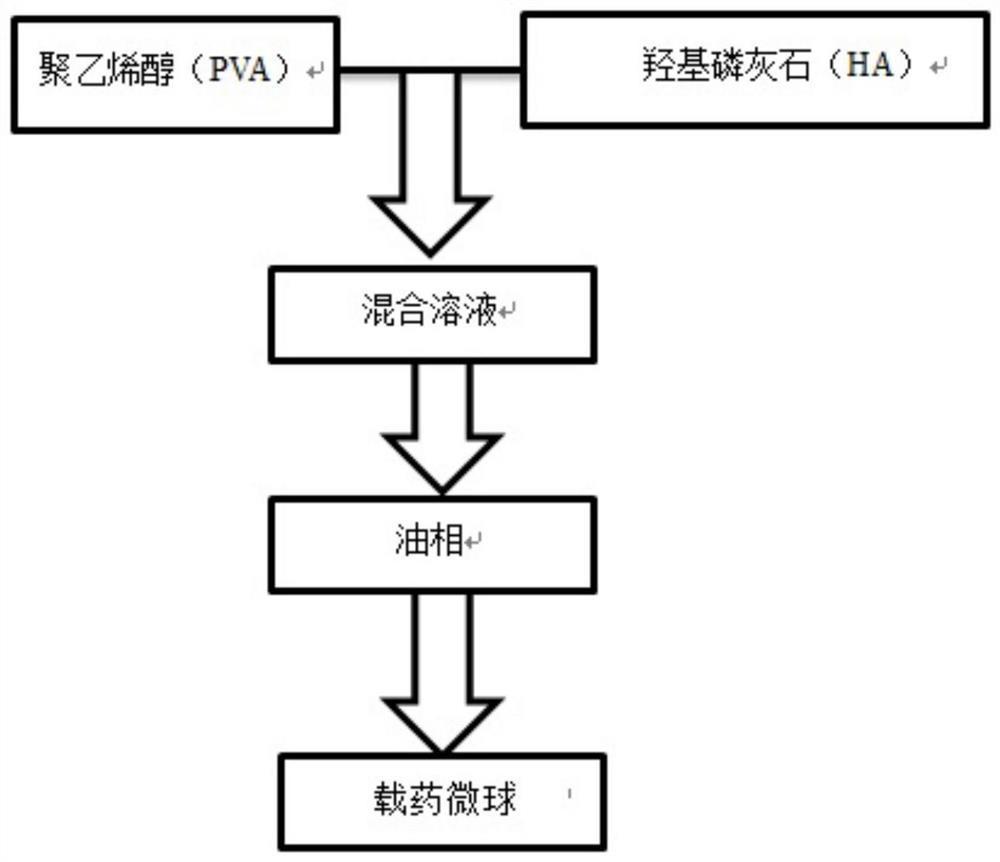

[0045] The preparation method of the drug-loaded microspheres of the present invention, as attached image 3 Shown, described preparation method comprises the steps:

[0046] (1) Mix the aqueous solution of polyvinyl alcohol and hydroxyapatite particles evenly; the mass ratio of polyvinyl alcohol to water is 1:100;

[0047] (2) Add concentrated hydrochloric acid to the uniformly mixed solution in step (1), the mass ratio of concentrated hydrochloric acid to polyvinyl alcohol is 14:100-15:100, and then add glutaraldehyde to obtain a pre-reaction solution, pre-reaction After 3 seconds, add the pre-reaction liquid dropwise to the mixed oil phase before the pre-reaction liquid condenses, and stir in an oil bath at 50°C-60°C to continue the reaction for at least 3 hours; the mixed oil phase includes liquid paraffin and dehydration Sorbitan fatty acid ester;

[0048] (3) Collect the reacted mixture in step (2), filter, wash, and freeze-dry to obtain drug-loaded microspheres;

[0...

Embodiment 2

[0051] An embodiment of the drug-loadable microspheres of the present invention, the drug-loadable microspheres described in this embodiment are prepared by the following method:

[0052] (1) Mix the aqueous solution of polyvinyl alcohol and hydroxyapatite particles evenly; the mass ratio of polyvinyl alcohol to water is 2:100;

[0053] (2) Add concentrated hydrochloric acid to the uniformly mixed solution in step (1), the mass ratio of concentrated hydrochloric acid to polyvinyl alcohol is 14:100-15:100. Then add glutaraldehyde to obtain a reaction solution. After pre-reaction for 10 seconds, add the pre-reaction solution dropwise to the mixed oil phase before the pre-reaction solution condenses, and stir in an oil bath at 50°C-60°C to continue the reaction for 4 hours; The mixed oil phase includes liquid paraffin and sorbitan fatty acid ester;

[0054] (3) Collect the reacted mixture in step (2), filter, wash, and freeze-dry to obtain drug-loaded microspheres;

[0055] In ...

Embodiment 3

[0057] An embodiment of the drug-loadable microspheres of the present invention, the drug-loadable microspheres described in this embodiment are prepared by the following method:

[0058] (1) Mix the aqueous solution of polyvinyl alcohol and hydroxyapatite particles evenly; the mass ratio of polyvinyl alcohol to water is 3:100;

[0059] (2) Add concentrated hydrochloric acid to the uniformly mixed solution in step (1), the mass ratio of concentrated hydrochloric acid to polyvinyl alcohol is 14:100-15:100. Then add glutaraldehyde to obtain a reaction solution. After pre-reaction for 30 seconds, add the pre-reaction solution dropwise to the mixed oil phase before the pre-reaction solution condenses, and stir in an oil bath at 50°C-60°C to continue the reaction for at least 3 hours. ; The mixed oil phase includes liquid paraffin and sorbitan fatty acid ester;

[0060] (3) Collect the reacted mixture in step (2), filter, wash, and freeze-dry to obtain drug-loaded microspheres;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com