Composite molecular sieve, desulfurization adsorbent, preparation method and application thereof

A composite molecular sieve and adsorbent technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, refined hydrocarbon oil, etc., can solve the problems of frequent regeneration of adsorbents, high energy consumption, low sulfur adsorption capacity, etc. , The effect of high adsorption capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

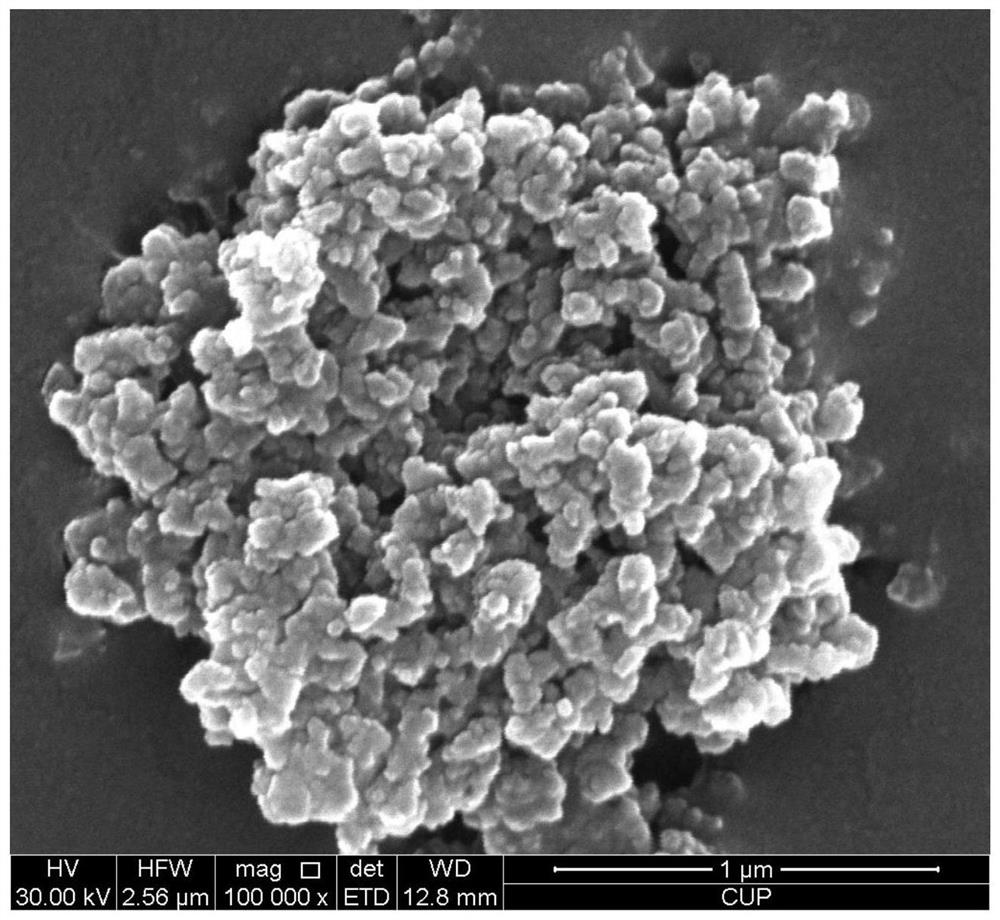

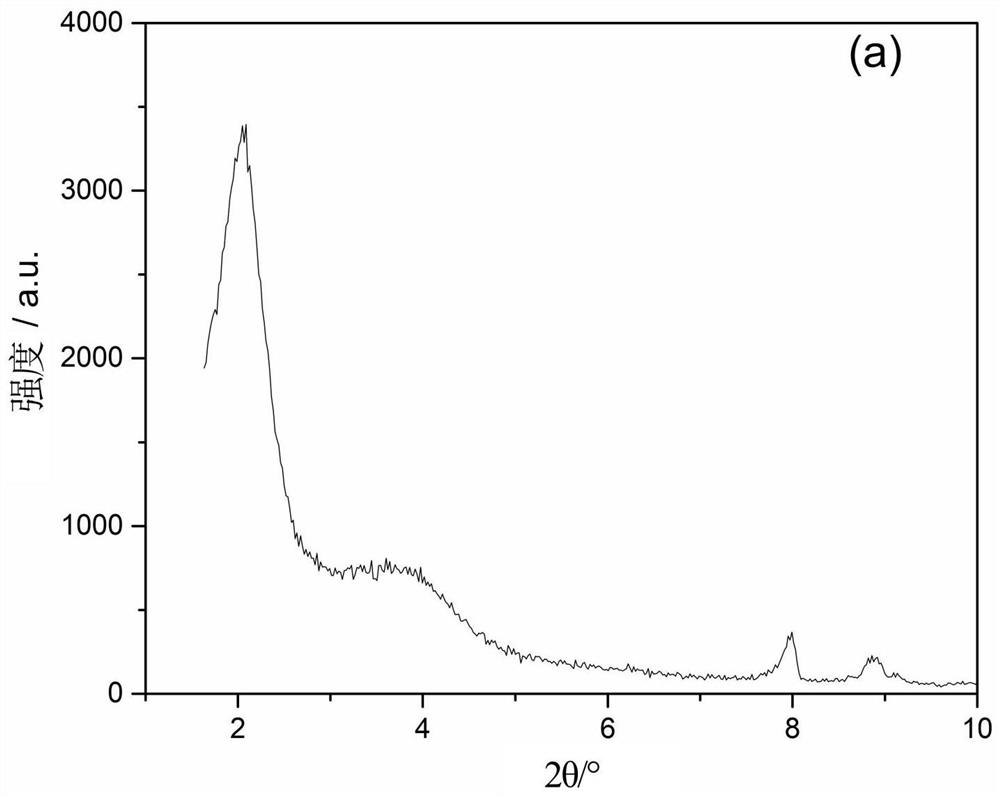

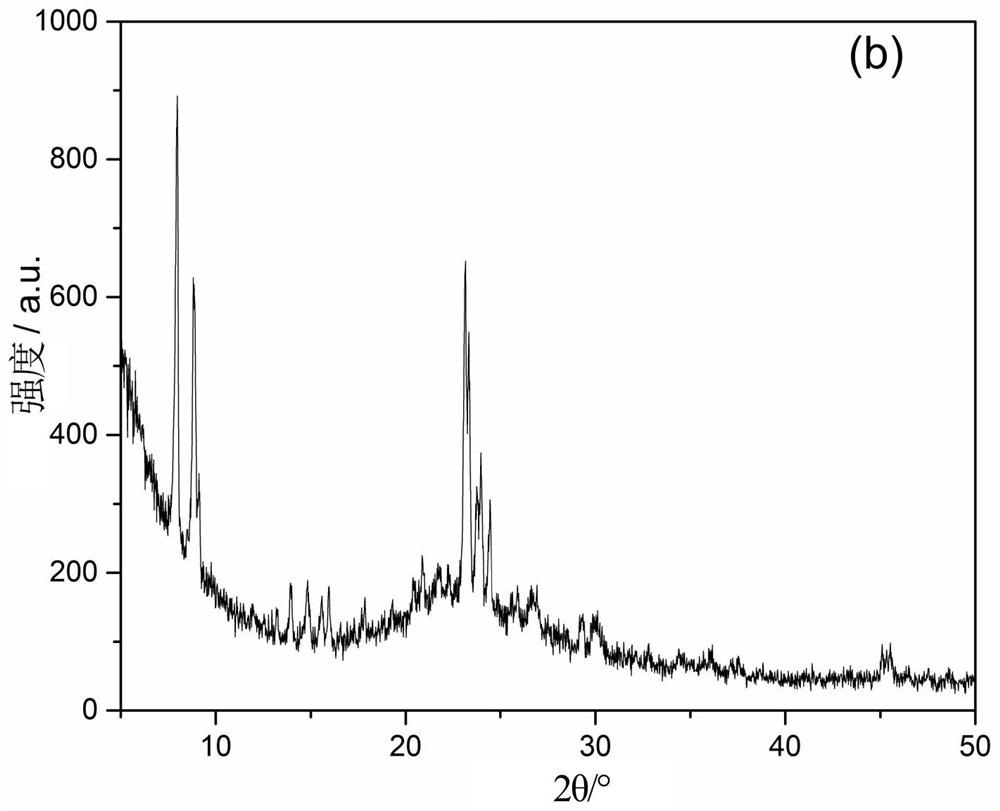

[0045] This embodiment provides a method for preparing a desulfurization adsorbent, the preparation process of which is as follows:

[0046] 1. Preparation of zinc in situ modified mordenite molecular sieve:

[0047] (1) Take 4.6g of Zn(NO 3 ) 2 ·6H 2 O is dissolved in the deionized water of 50ml, prepares zinc nitrate solution, stand-by;

[0048](2) Dissolve 12.0g of NaOH in 200ml of deionized water, then add 19.5g of NaAlO 2 , stirred until a clear solution is formed;

[0049] (3) Add 306.0g of silica sol (SiO 2 Content 30wt%), after stirring to form sol, then pour into zinc nitrate solution, stir evenly;

[0050] (4) Transfer the sol solution to a hydrothermal reaction kettle, and crystallize at 150° C. for 90 hours;

[0051] (5) After the crystallization is completed, the product is filtered, dried at 100°C for 10 hours, and then roasted at 500°C for 3 hours to obtain a zinc in-situ modified mordenite molecular sieve, calculated as zinc oxide, zinc The content is a...

Embodiment 2

[0112] This embodiment provides a method for preparing a desulfurization adsorbent, the preparation process of which is as follows:

[0113] 1. Preparation of zinc in situ modified ZSM-5 molecular sieve:

[0114] (1) Take 2.5g of ZnCl 2 Dissolve in 50ml of deionized water to prepare a zinc chloride solution for use;

[0115] (2) Dissolve 14.2g of NaOH in 400ml of deionized water, then add 12.5g of NaAlO 2 And the tetraethylammonium hydroxide solution (25wt%) of 25.0g, stir until forming clear solution;

[0116] (3) Add 294.0g of silica sol (SiO 2 Content 30wt%), after stirring to form sol liquid, then pour into zinc chloride solution, stir evenly;

[0117] (4) Transfer the sol solution to a hydrothermal reaction kettle, and crystallize at 180° C. for 40 hours;

[0118] (5) After the crystallization is completed, filter the product, dry it at 110°C for 10 hours, and then roast it at 500°C for 3 hours to obtain a zinc in-situ modified ZSM-5 molecular sieve, calculated as zi...

Embodiment 3

[0129] This embodiment provides a method for preparing a desulfurization adsorbent, the preparation process of which is as follows:

[0130] 1. Preparation of zinc in situ modified ZSM-5 molecular sieve:

[0131] (1) Take 4.2g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 40ml deionized water to prepare a zinc nitrate solution for use;

[0132] (2) Dissolve 14.2g of NaOH in 400ml of deionized water, then add 7.9g of NaAlO 2 And the tetraethylammonium hydroxide solution (25wt%) of 25.0g, stir until forming clear solution;

[0133] (3) Add 327.0g of silica sol (SiO 2 Content 30wt%), after stirring to form sol, then pour into zinc nitrate solution, stir evenly;

[0134] (4) Transfer the sol solution to a hydrothermal reaction kettle, and crystallize at 180° C. for 40 hours;

[0135] (5) After the crystallization is completed, filter the product, dry it at 110°C for 10 hours, and then roast it at 500°C for 3 hours to obtain a zinc in-situ modified ZSM-5 molecular sieve, calculate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com