Fe3O4/porous carbon nanofiber and preparation method and application thereof

A technology of nanofibers and porous carbons, applied in nanocarbons, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of low electrical conductivity, lack of surface area, high contact resistance and insufficient capacitance display, etc., to achieve fast ion transmission, electrochemical The effect of excellent performance and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

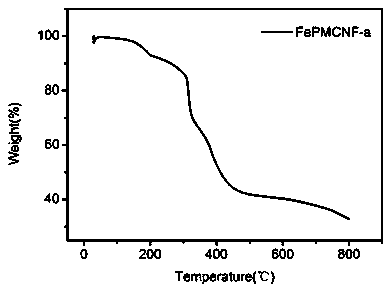

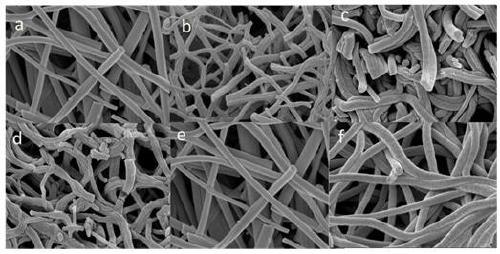

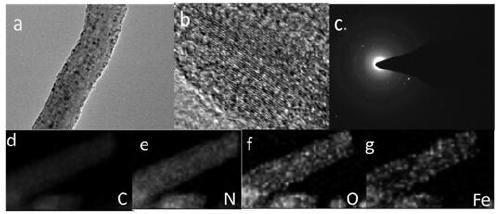

[0042] The embodiment of the present invention provides a kind of Fe 3 o 4 / Porous carbon nanofibers and their preparation methods and applications solve the problem of relatively poor cycle stability of pseudocapacitor electrode materials in the prior art, and are prone to structural collapse and iron oxide as a pseudocapacitor electrode material has high contact resistance and insufficient capacitance display The problem.

[0043] The specific technical solution to solve the above problems in the embodiment of the application is: a kind of Fe 3 o 4 A preparation method for porous carbon nanofibers, comprising the following steps:

[0044] S1. Dissolving straw liquefied carbon, polyacrylonitrile, polymethyl methacrylate and iron acetylacetonate in N,N-dimethylformamide and mixing to obtain an electrospinning solution;

[0045] Specifically, the straw is one of hemp straw, corn straw, wheat straw, rice straw and rapeseed straw.

[0046] Specifically, the specific preparat...

Embodiment 2

[0055] A kind of Fe of the embodiment of the present invention 3 o 4 A preparation method for porous carbon nanofibers, comprising the following steps:

[0056] S5: Weigh a certain amount of wheat straw, wash it with deionized water, dry it in an oven at 80°C for 8 hours, crush the dried straw and pass it through a 100-mesh sieve, add 5 times the mass of straw powder and 10% of the mass of phenol and straw powder Phosphoric acid, wherein phosphoric acid is used as a catalyst, refluxed in an oil bath at 160°C for 2.5h, cooled to room temperature to obtain straw liquefied carbon;

[0057] S6: 1 part of liquefied carbon from corn stalks, 9 parts of polyacrylonitrile and 0.3 part of iron acetylacetonate were dissolved in N,N-dimethylformamide and mixed to obtain an electrospinning solution;

[0058] S7: Add the electrospinning solution into a syringe with a stainless steel needle, the positive high voltage of electrospinning is 15kV, the negative high voltage is -2kV, the distan...

Embodiment 3

[0061] A kind of Fe of the embodiment of the present invention 3 o 4 A preparation method for porous carbon nanofibers, comprising the following steps:

[0062] S5: Weigh a certain amount of hemp stalks, wash them with deionized water, and dry them in an oven at 80°C for 8 hours. Crush the dried stalks and pass them through a 100-mesh sieve. Add 5 times the weight of phenol and 10% of the weight of the straw powder Phosphoric acid, wherein phosphoric acid is used as a catalyst, refluxed in an oil bath at 160°C for 2.5h, cooled to room temperature to obtain straw liquefied carbon;

[0063] S6: Take 1 part of liquefied carbon of cannabis straw, 9 parts of polyacrylonitrile, 1.11 parts of polymethyl methacrylate and 0.3333 parts of iron acetylacetonate, dissolve them in N, N-dimethylformamide and mix them to obtain an electrospinning solution;

[0064] S7: Add the electrospinning solution into a syringe with a stainless steel needle, the positive high voltage of electrospinning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com