Preparation process of novel transparent ceramic with high light transmittance

A technology of transparent ceramics and preparation technology, which is applied in the field of ceramic preparation, can solve the problems that micropores cannot be eliminated, restrict the development and production application of transparent ceramics, and the transparency of ceramics cannot be significantly improved, so as to promote material migration and grain boundary movement, reduce Generation of impurities and pores, effects of improving transparency and strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

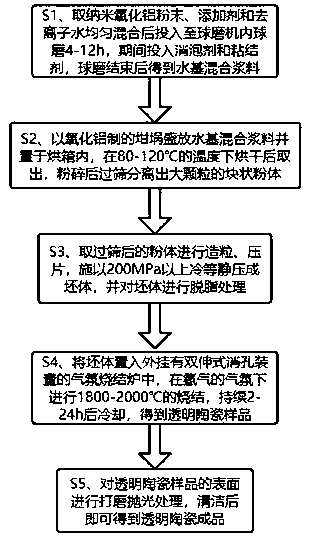

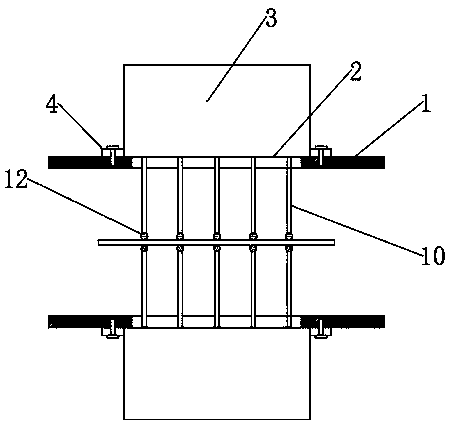

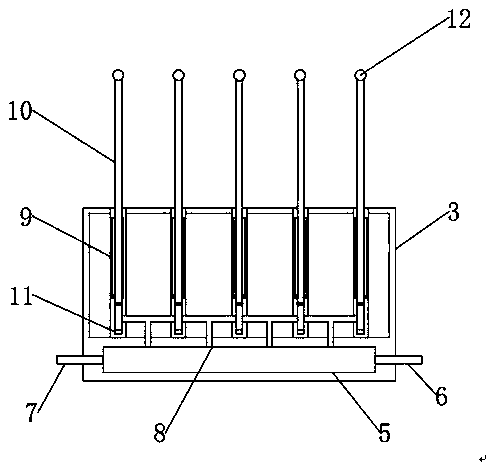

[0041] see Figure 1-2 , a high-transmittance novel transparent ceramic preparation process, comprising the following steps:

[0042] S1. Take the nano-alumina powder, additives and deionized water and mix them evenly, put them into the ball mill for 4 hours, during which defoamer and binder are put in, and the water-based mixed slurry is obtained after the ball milling;

[0043] S2. The water-based mixed slurry is placed in an alumina crucible and placed in an oven, dried at a temperature of 80°C, taken out, crushed and sieved to separate large-grain block powder;

[0044] S3. Take the sieved powder for granulation and tabletting, apply cold isostatic pressing above 200MPa to form a green body, and degrease the green body;

[0045] S4. Put the green body into an atmosphere sintering furnace with a double-extending hole elimination device, and sinter at 1800°C in a hydrogen atmosphere. After cooling for 2 hours, the sintering temperature is controlled at a heating rate of 6°C...

Embodiment 2

[0055] see Figure 1-2 , a high-transmittance novel transparent ceramic preparation process, comprising the following steps:

[0056] S1. Take the nano-alumina powder, additives and deionized water and mix them evenly, put them into the ball mill for 8 hours, during which defoamer and binder are put in, and the water-based mixed slurry is obtained after the ball milling;

[0057] S2. The water-based mixed slurry is placed in an alumina crucible and placed in an oven, dried at a temperature of 100°C, taken out, pulverized, and sieved to separate large particle block powder;

[0058] S3. Take the sieved powder for granulation and tabletting, apply cold isostatic pressing above 200MPa to form a green body, and degrease the green body;

[0059] S4. Put the green body into an atmosphere sintering furnace with a double-extended hole elimination device, and sinter at 1900°C in a hydrogen atmosphere. After cooling for 12 hours, the sintering temperature is controlled at a heating rat...

Embodiment 3

[0065] see Figure 1-2 , a high-transmittance novel transparent ceramic preparation process, comprising the following steps:

[0066] S1. Take the nano-alumina powder, additives and deionized water and mix them evenly, put them into the ball mill for 12 hours, during which defoamer and binder are put in, and the water-based mixed slurry is obtained after the ball milling;

[0067] S2. The water-based mixed slurry is placed in an alumina crucible and placed in an oven, dried at a temperature of 120° C., taken out, crushed and sieved to separate large-grain block powder;

[0068] S3. Take the sieved powder for granulation and tabletting, apply cold isostatic pressing above 200MPa to form a green body, and degrease the green body;

[0069] S4. Put the green body into an atmosphere sintering furnace with a double-extended hole elimination device, sinter at 2000°C in a hydrogen atmosphere, and cool after 24 hours. The sintering temperature is controlled at a heating rate of 8°C / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com