A method and system for microwave-assisted regeneration of a three-way catalyst

A three-way catalyst and microwave-assisted technology, which is applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of automatic management of unfavorable configuration control systems, insignificant improvement of catalyst regeneration efficiency, and regeneration activity The problem of large amount of component supplementation and impregnation can be achieved to facilitate the automatic management of radiation conditions, improve energy utilization, and reduce uneven thermal stress damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

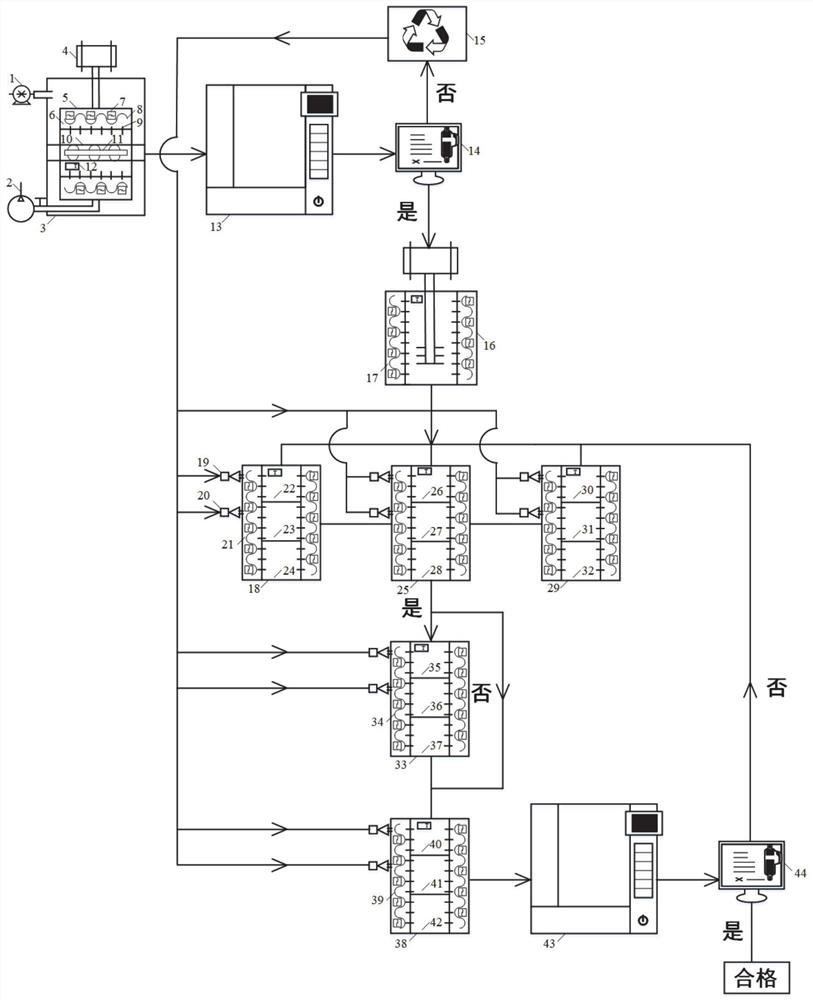

Method used

Image

Examples

Embodiment 1

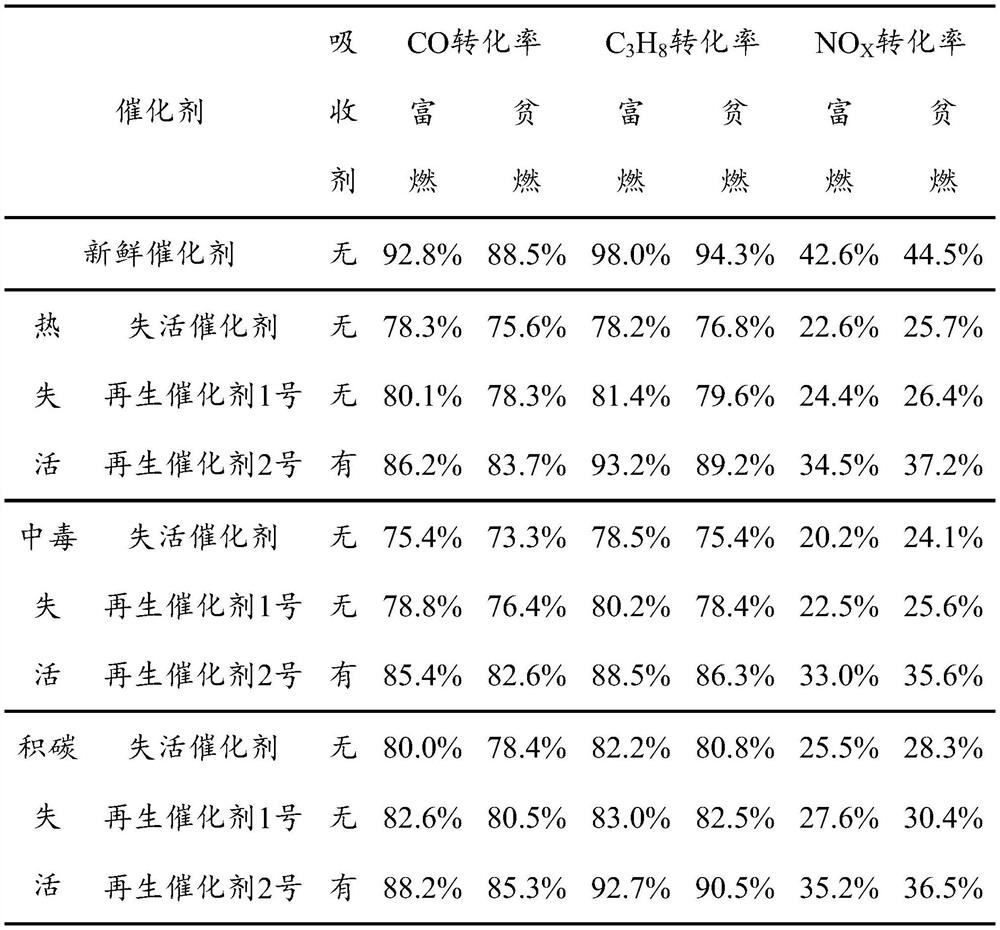

[0123] The test materials are the same model of seven-generation Accord 2.4 vehicle-mounted fresh three-way catalyst and deactivated three-way catalyst, and microwave-assisted fuel vehicle three-way catalyst regeneration is performed as follows:

[0124] In the first step, the catalyst is fixed in the pretreatment device, and after 0.2MPa nitrogen is purged on the surface and inside of the three-way catalyst for 20 minutes, the dispensing device adds dodecylbenzene with a volume ratio of 2:1 to the pretreated three-way catalyst Sodium sulfonate to the pretreatment device, at 30°C, the ultrasonic controller assembly adjusts the ultrasonic power to 200W, the pulse width is 10ms, and the power density is 0.30W / cm 2 , the first microwave control component adjusts the microwave energy to 20W / kg, the microwave frequency to 1000MHz, the ultrasonic microwave chemical reactor cooperates with sodium dodecylbenzenesulfonate to deeply clean the catalyst for 60min, the ultrasonic power of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com