Holding agent for weakly weathered limestone fracture integrity

A limestone, weak weathering technology, applied in the directions of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of large particle size and impermeability, achieve low cost and improve compression resistance. The effect of strength and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

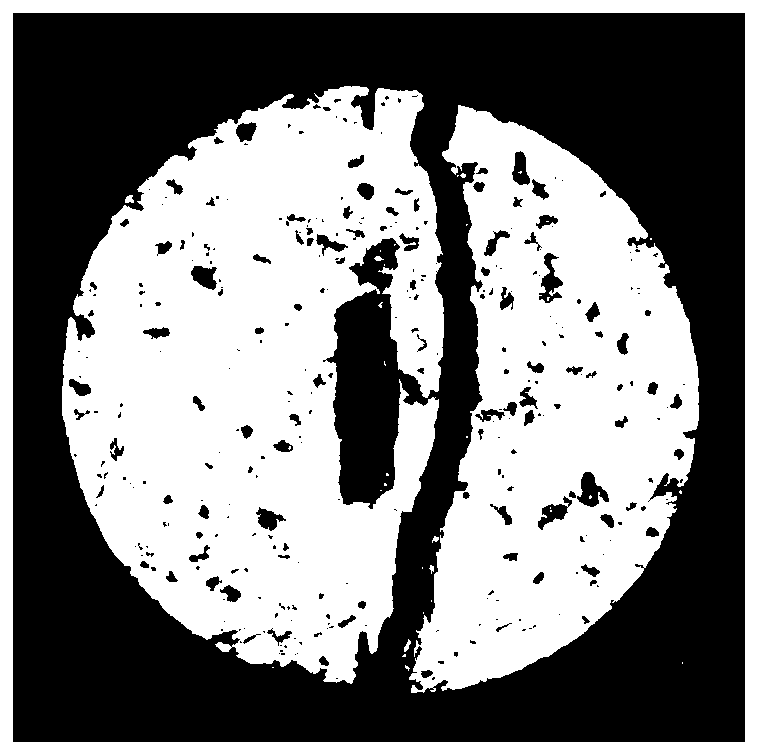

Image

Examples

Embodiment 1

[0040] A supporting agent for the integrity of weakly weathered limestone fractures, the raw materials and dosage are shown in the following table:

[0041]

[0042]

[0043] The preparation method of component A is: add E-44 epoxy resin, n-butyl polyacrylate, lignin and ethanol according to the raw materials and dosage ratio in the above table into the reaction kettle with its own temperature adjustment system and stirring device, Stir and react at 50°C for 30 minutes, then add diallyl phthalate, nano-graphene particles, polyglycidyl methacrylate, half the amount of resorcinol bisglycidyl ether, and stir well Then gradually add the remaining half of the amount of resorcinol bisglycidyl ether and liquid nitrile rubber, that is, resorcinol bisglycidyl ether is added in two times, and then continue to react for 1 to 2 hours, and then filter to obtain component A ,spare.

[0044] The preparation method of component B is: in the reaction kettle with its own temperature adju...

Embodiment 2

[0047]A supporting agent for the integrity of weakly weathered limestone fractures, the raw materials and dosage are shown in the following table:

[0048]

[0049]

[0050] The preparation method of component A is: add E-44 epoxy resin, n-butyl polyacrylate, lignin and ethanol according to the raw materials and dosage ratio in the above table into the reaction kettle with its own temperature adjustment system and stirring device, Stir and react at 50°C for 30 minutes, then add 1,2-diallyl phthalate, micron graphite particles, polyglycidyl methacrylate, add half the amount of resorcinol bisglycidyl ether, and stir well Gradually add the remaining half of the amount of resorcinol bisglycidyl ether and liquid nitrile rubber, that is, resorcinol bisglycidyl ether is added in two times, and then continue to react for 1 to 2 hours, and then filter to obtain component A. spare.

[0051] The preparation method of component B is: in the reaction kettle with its own temperature ...

Embodiment 3

[0054] A supporting agent for the integrity of weakly weathered limestone fractures, the raw materials and dosage are shown in the following table:

[0055]

[0056] The preparation method of component A is: add E-44 epoxy resin, n-butyl polyacrylate, lignin and ethanol according to the raw materials and dosage ratio in the above table into the reaction kettle with its own temperature adjustment system and stirring device, Stir and react at 50°C for 30 minutes, then add 1,2-diallyl phthalate, micron graphite particles, polyglycidyl methacrylate, add half the amount of resorcinol bisglycidyl ether, and stir well Gradually add the remaining half of the amount of resorcinol bisglycidyl ether and liquid nitrile rubber, that is, resorcinol bisglycidyl ether is added in two times, and then continue to react for 1 to 2 hours, and then filter to obtain component A. spare.

[0057] The preparation method of component B is: in the reaction kettle with its own temperature adjustment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com