Preparation and seeding method of a kind of ectomycorrhizal fungus granule

A technology of ectomycorrhizal fungus and granules, which can be applied in botany equipment and methods, horticulture, agriculture, etc., and can solve the problem that input and output are not suitable for large-scale promotion and application, not suitable for large-scale promotion and application, and reduce the activity of bacteria, etc. problem, to achieve the effects of simple production and sowing methods, good water retention, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

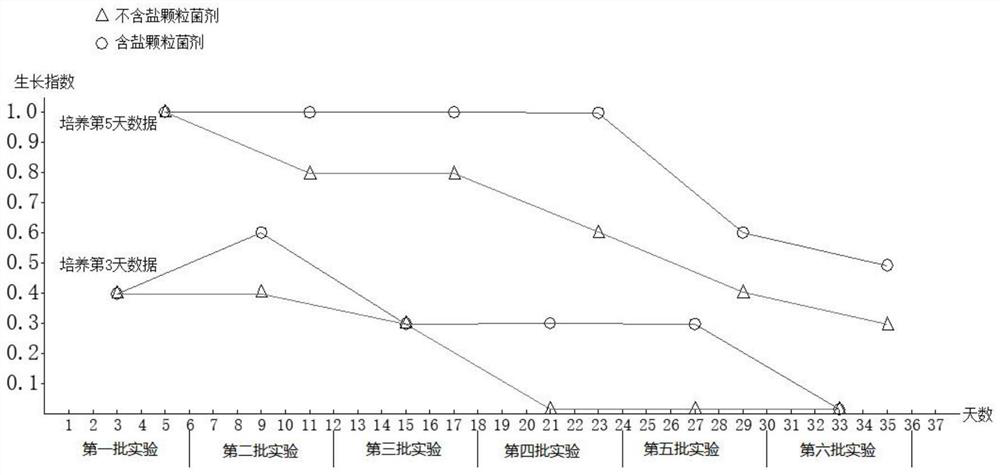

Examples

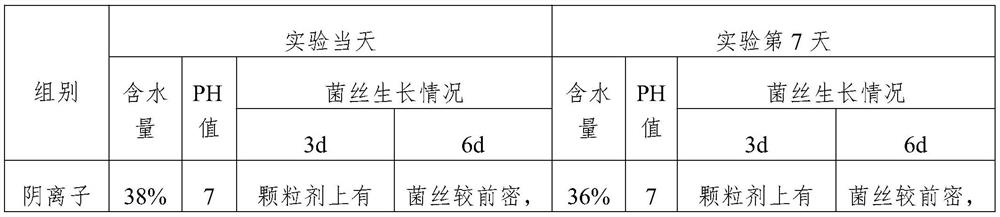

Embodiment 1

[0092] A preparation method for ectomycorrhizal fungus granule strains, comprising the following steps:

[0093] (1) placing the ectomycorrhizal bacteria in the container, stirring and breaking the mycelium to obtain the ectomycorrhizal bacteria liquid; the stirring speed is 250r / min, and the time is 3min;

[0094] (2) The nutrient solution is added in the ectomycorrhizal solution of step (1) and stirred evenly to obtain a mixed solution; the nutrient solution and the ectomycorrhizal solution are mixed according to equal volumes; the nutrient solution consists of the following Made from raw materials in parts by weight: 20 parts of raw corn flour, 10 parts of glucose, 0.3 parts of calcium chloride, 0.3 parts of sodium chloride, 1 part of magnesium sulfate, 2 parts of potassium dihydrogen phosphate, 0.05 parts of VB1, potassium indole butyrate 0.5 parts; the preparation method is: add raw corn flour to water, heat and stir at 60°C to dissolve the raw corn flour into corn liquid...

Embodiment 2

[0101] A preparation method for ectomycorrhizal fungus granule strains, comprising the following steps:

[0102] (1) placing the ectomycorrhizal bacteria in the container, stirring and breaking the mycelium to obtain the ectomycorrhizal bacteria liquid; the stirring speed is 300r / min, and the time is 5min;

[0103] (2) The nutrient solution is added in the ectomycorrhizal solution of step (1) and stirred evenly to obtain a mixed solution; the nutrient solution and the ectomycorrhizal solution are mixed according to equal volumes; the nutrient solution consists of the following Made from raw materials in parts by weight: 50 parts of raw corn flour, 40 parts of glucose, 1 part of calcium chloride, 1 part of sodium chloride, 1-3.5 parts of magnesium sulfate, 5 parts of potassium dihydrogen phosphate, 0.15 parts of VB1, indole 2 parts potassium acid potassium; the preparation method is as follows: add raw corn flour to water, heat and stir at 100°C to dissolve the raw corn flour i...

Embodiment 3

[0110] A preparation method for ectomycorrhizal fungus granule strains, comprising the following steps:

[0111] (1) placing the ectomycorrhizal bacteria in the container, stirring and breaking the mycelium to obtain the ectomycorrhizal bacteria liquid; the stirring speed is 260r / min, and the time is 3.5min;

[0112] (2) The nutrient solution is added in the ectomycorrhizal solution of step (1) and stirred evenly to obtain a mixed solution; the nutrient solution and the ectomycorrhizal solution are mixed according to equal volumes; the nutrient solution consists of the following Made from raw materials in parts by weight: 30 parts of raw corn flour, 20 parts of glucose, 0.5 parts of calcium chloride, 0.5 parts of sodium chloride, 1.5 parts of magnesium sulfate, 3 parts of potassium dihydrogen phosphate, 0.08 parts of VB1, potassium indole butyrate 1.0 parts; the preparation method is: add raw corn flour to water, heat and stir at 70°C to dissolve the raw corn flour into corn l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com