Flexible reaction device and method for trifluoroethanol/trifluoroethyl methacrylate

A technology of trifluoroethyl methacrylate and trifluoroethanol, which is applied in the field of fluorine-containing fine chemicals, can solve problems such as unsatisfactory reaction rate and product yield, reduced income, and difficult separation, and achieve production capacity The effect of high utilization rate, stable product quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

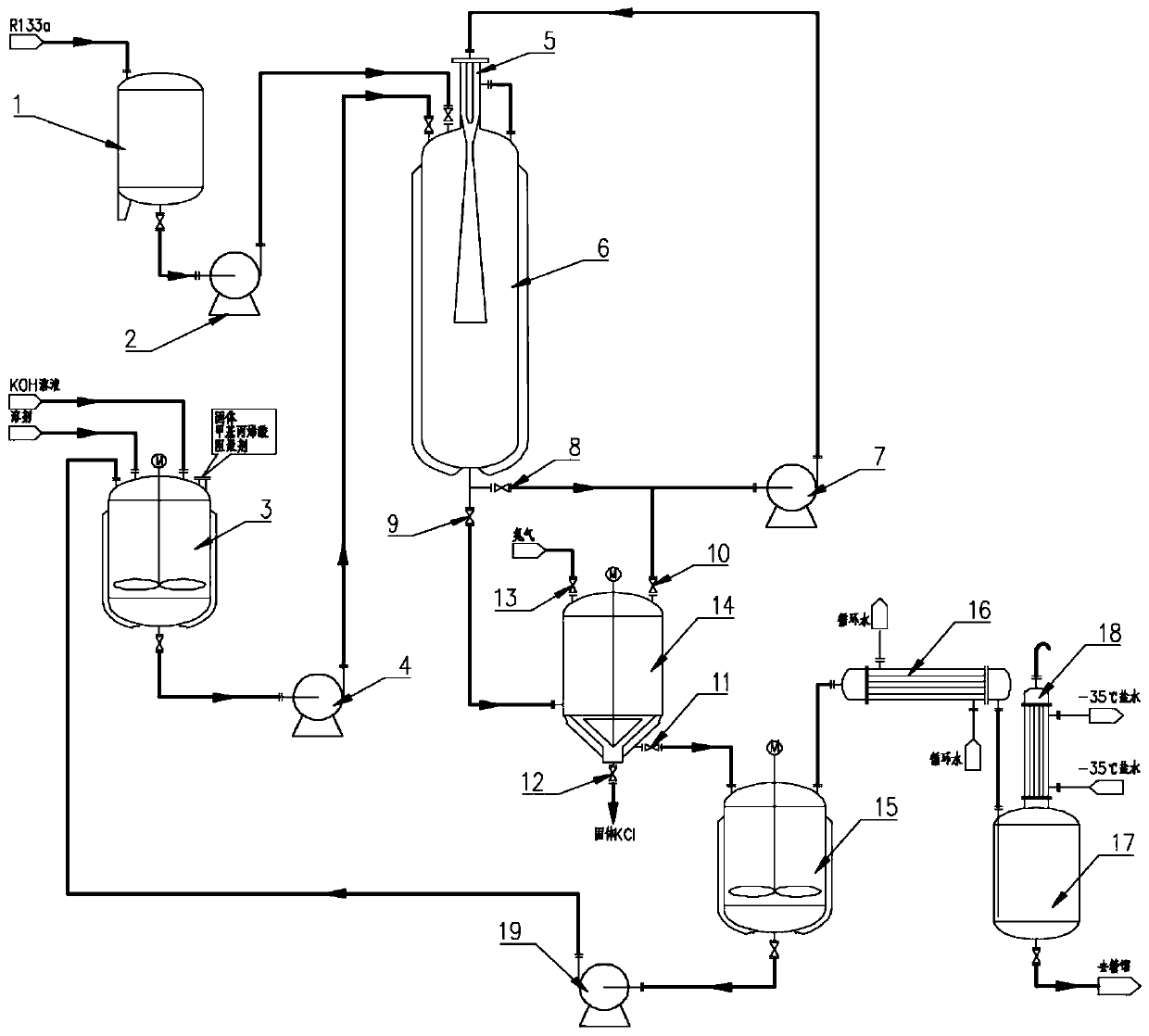

[0049] Such as figure 1 As shown, a flexible reaction device of trifluoroethanol / trifluoroethyl methacrylate, the device includes R-133a metering tank 1, R-133a metering pump 2, raw material mixing kettle 3, raw material feeding pump 4, Venturi Injector 5, reactor 6, reaction circulation pump 7, filter 14, distillation kettle 15, distillation condenser 16, receiving tank 17, tail gas condenser 18, bottom feeding pump 19;

[0050] The Venturi injector 5 is arranged on the upper end of the reactor 6, and the suction port of the Venturi injector 5 is communicated with the side top of the reactor 6 by an air duct; the R-133a metering tank 1 is passed through the R-133a metering pump 2 It is connected with the feed port of the reactor 6, the raw material mixing tank 3 is connected with the feed port of the reactor 6 through the raw material feeding pump 4, and the feed port at the lower end of the reactor 6 passes through the inlet of the reaction circulation pump 7 and the Venturi...

Embodiment 2

[0055] A flexible reaction device of trifluoroethanol / trifluoroethyl methacrylate as described in Example 1, the difference is: the medium of the tail gas condenser 18 provided at the upper end of the receiving tank 17 is -35°C to -30°C °C frozen brine. The outer side of the raw material mixing kettle 3 is provided with a heating or cooling jacket, and the raw material mixing kettle 3 is provided with a stirring device. A heating or cooling jacket is provided on the outside of the still 15, and a stirring device is provided on the still 15.

Embodiment 3

[0057] Utilize the method for producing trifluoroethanol by the production device described in embodiment 1 or 2, comprise steps as follows:

[0058] (1) first open the second valve 9 and the third valve 10 on the filter, close the first valve 8, the fourth valve 11, the fifth valve 12, the sixth valve 13, through the raw material mixing kettle 3, to the reactor 6 and Squeeze metered N-methylpyrrolidone solvent into the filter 14, then close the second valve 9 and the third valve 10, open the first valve 8, start the reaction circulation pump 7 to circulate, and form the injection reaction loop; 48wt%KOH After the aqueous solution and N-methylpyrrolidone solvent are mixed in the raw material mixing tank 3, they are pumped into the reactor 6 by the raw material feeding pump 4, and then the R-133a is injected into the R-133a metering tank 1 through the R-133a metering pump 2 Reactor 6; the molar ratio of KOH to N-methylpyrrolidone is 1:5~6, and the molar ratio of R-133a to KOH i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com